|

市場調查報告書

商品編碼

1406120

晶片貼裝設備:市場佔有率分析、產業趨勢/統計、成長預測,2024-2029Die Attach Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029 |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

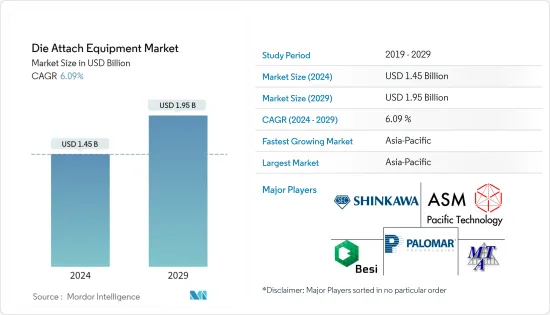

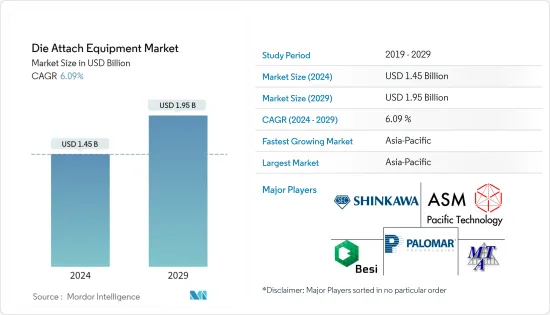

晶片貼裝設備市場規模預計到 2024 年為 14.5 億美元,預計到 2029 年將達到 19.5 億美元,在預測期內(2024-2029 年)複合年成長率為 6.09%。

物聯網 (IoT) 設備中擴大使用堆疊晶粒技術推動了成長。最近的趨勢表明,由於醫療、軍事、光電和無線電子等新興和現有應用,對混合電路的需求仍然強勁。

主要亮點

- C2W混合鍵合是一種很有前景的新技術,可實現直接 Cu-Cu 鍵合,並可取代 3D 堆疊記憶體和高階邏輯應用中的 TCB。然而,C2W混合鍵合仍處於早期階段。 2.5D結構的邏輯元件預計將於2022年至2023年上市,將可大幅支撐設備市場的成長。

- 對金錫共晶貼片技術的需求將推動市場的發展。傳統上,晶片採用各種晶片黏合產品進行安裝,包括金屬填充導電環氧樹脂、高鉛焊料和金矽焊料,以確保設備在整個生命週期內具有可靠的功能。然而,由於發熱增加、對更小型設備的需求、RoHS 和 REACH 的頒布以及向 GaAs 晶片的轉變,傳統材料的使用受到限制。對裝置高可靠性的需求促使工程師評估各種用於晶粒連接的新材料。

- 對分立功率元件的需求正在推動市場發展。銅夾作為傳統引線接合法和帶狀鍵結的替代品越來越受歡迎。晶片連接功能是分立功率元件封裝解決方案的標誌。寬能能隙半導體晶粒技術(SiC 和 GaN)的採用帶來了新的創新封裝解決方案,包括銀燒結晶片連接(材料包括環氧模塑膠和互連材料)。 EV/HEV 應用中從分立 SiC 逐漸過渡到 SiC 模組、嵌入式晶粒封裝系統以及 GaN 裝置在多晶片系統中的整合只是此類趨勢的幾個例子。因此,對分立功率元件晶片貼裝設備的需求不斷增加。

- 然而,主要是加工過程中的尺寸變化、使用壽命以及透過設備加工過程中移動部件的機械不平衡對設備的功能提出了課題,並可能抑制市場。

- 此外,COVID-19 的影響不會對設備需求產生重大影響。例如,在大流行期間,Palomar Technologies 宣布已受委託生產關鍵的半導體元件,以應對 COVID-19。該公司的 3880 貼片機設備訂單加速成長,該設備支援無線通訊和網路頻寬、遠端醫療、機器人物聯網和視訊會議。這種加速對於其他市場參與者來說也是類似的。因此,疫情期間對設備的需求仍然較高。由於對物聯網設備、自動化和智慧技術的需求,這種需求將在大流行後繼續成長。

晶片貼裝設備市場趨勢

LED將實現顯著成長

- 晶片黏接材料對於中、高和超高高功率LED 的性能和可靠性至關重要。隨著 LED普及的提高,對晶片貼裝設備的需求也增加。為特定晶片結構和應用選擇適當的晶片黏接材料取決於多種考慮因素,包括封裝製程(吞吐量和產量比率)、性能(熱和光輸出)、可靠性(流明維持率)和成本。共晶金錫、銀填充環氧樹脂、焊料、矽膠和燒結材料均已用於 LED 晶片貼裝。

- 例如,SFE提供了一種採用環氧樹脂黏劑的黏合方法,LED環氧樹脂晶片黏合機的特點是索引時間為0.2秒/週期(90%運轉率),晶片尺寸為250*250標準,並且透過兩種方式提供引線框架辨識相機。其軟體功能提供自動安裝水平和拾取水平教學功能。

- 此外,導電黏劑(主要是載銀環氧樹脂)構成了最廣泛使用的 LED 熱晶片黏合材料(單位)。它們與現有的後端封裝設備相容,並提供有吸引力的成本/性能平衡(通常高達 50W/mK 熱量,具有二次回流相容性)。由於它附著在裸矽上,因此它是無後端金屬化晶粒(例如矽基氮化鎵)的最優選材料。

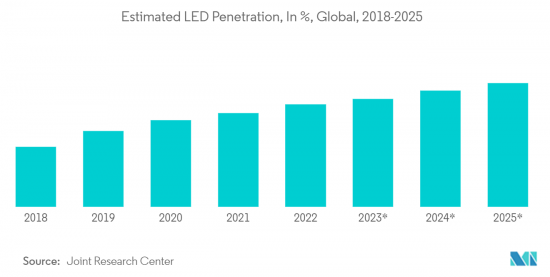

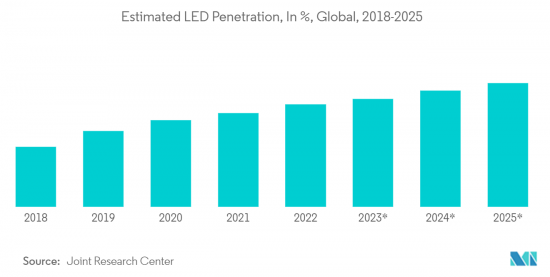

- 而且,在LED市場上,有許多對手和競爭者,但ASM是這個市場的突出參與者之一,其LED環氧樹脂高速固晶機AD830在LED市場上佔據主導地位。隨著越來越多的國家尋求逐步淘汰傳統燈泡,LED 繼續佔據市場主導地位。根據聯合研究中心的數據,基於銷售額的LED普及正在增加,預計到2025年將達到75.8%的普及。這增加了晶片貼裝設備市場的需求。

- 此外,2022年9月,Palomar Technologies宣布推出新型貼片機3880-II,該機榮獲2022年軍事+航空電子創新獎。這款新機器包括可最大限度提高生產率、將編程時間縮短高達 95% 並提高整體鍵合機生產率的選項。

亞太地區市場成長顯著

- 亞太地區是晶片貼裝設備產業顯著成長的地區。全球超過 60% 的 OSAT(外包半導體組裝和測試)公司總部位於亞太地區。這些 OSAT 公司在其半導體製造製程中使用晶片貼裝設備。此外,該地區 IDM(整合設備製造商)的數量正在增加,預計這將很快推動市場成長。

- 在中國和台灣,光電、MEMS和MOEMS等多種裝置被用於智慧型手機、穿戴式裝置和白色家電等電子產品的大規模生產。所有這些設備在零件組裝過程中都需要晶片連接設備。

- 此外,預計韓國、中國(主要是日本)的老年人口在預測期內將加快醫療服務的需求,人工呼吸器、透析和包含 MEMS 壓力感測器的血壓監測設備等設備。亞太經社會預測,該地區60歲及以上老年人口將從目前的9.55人增加到2025年的10.64人,2050年將增加到18.44人,佔世界人口的60%。對 MEMS 壓力感測器晶片貼裝設備的需求推動了該市場的成長。

- 此外,由於政府的舉措,印度許多智慧城市正在發展,預計將採用電子解決方案用於監視、維護和監控等目的。根據smartcities.gov.in報道,中央政府已撥款9.77億美元用於60個此類智慧城市的發展。這促使了對更多 CMOS 影像感測器的需求,進一步推動了市場成長。

- 高功率雷射在工業領域有廣泛的需求,其應用範圍廣泛,包括切割、焊接和機械加工。該公司正在轉向雷射技術,以利用其高性能和可靠性。雷射二極體的進步顯著增加了對環氧樹脂加工設備和共晶接合技術的需求。

- 隨著物聯網、人工智慧和ADAS的發展,記憶體的需求預計將進一步增加。因此,比以往任何時候都更需要提高記憶體晶片製造的生產率並提高後處理中的裝置可靠性。為了解決這個問題,2022 年 8 月,史丹佛大學的工程師創建了一種更有效率、更靈活的 AI 晶片。這有可能將人工智慧的力量帶入小型邊緣設備,有助於提高記憶體製造的吞吐量和可靠性。

晶片貼裝設備產業概況

由於本地和全球參與者的存在滲透到激烈的市場中,晶片貼裝設備市場呈現碎片化。此外,隨著公司專注於透過開發和聯盟來提高設備效能,例如吞吐量和產量比率,市場競爭正在加劇。

- 2022 年 10 月,Hermetic Solutions Group (HSG) 從 RHP Technologies 收購了 DiaCool 智慧財產權。這擴大了 HSG 的產品範圍,並在未來為客戶提供更多選擇。 HSG 用於散熱器、晶片片和散熱器的 DiaCool 鑽石複合材料為客戶提供了優於傳統層壓板和 MMC 材料的顯著優勢。

- 2022 年 10 月,Kulicke 和 Soffa 收到了多個熱壓解決方案的新訂單,並成功將其第一台助焊劑熱壓接合機 (TCB)出貨給主要客戶,鞏固了其在先進LED 組件領域的地位。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 市場概況

- 市場促進因素

- 對 AuSn 共晶晶片貼裝技術的需求不斷成長

- 對分立功率元件的需求

- LED 區隔市場顯著成長

- 市場抑制因素

- 加工和使用壽命期間的尺寸變化和機械不平衡

- 價值鏈分析

- 產業吸引力—五力分析

- 新進入者的威脅

- 買家/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭公司之間敵對關係的強度

- COVID-19 市場影響評估

第5章市場區隔

- 類型

- 固晶機

- 覆晶鍵合機

- 接合技術

- 環氧樹脂

- 共晶

- 軟焊料

- 混合鍵合

- 其他

- 應用

- 記憶

- 射頻,MEMS

- LED

- CMOS影像感測器

- 邏輯

- 光電子/光電

- 其他

- 地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東/非洲

第6章 競爭形勢

- 公司簡介

- Palomar Technologies, Inc.

- Shinkawa Ltd.

- MicroAssembly Technologies, Ltd.

- ASM Pacific Technology Limited

- Be Semiconductor Industries NV

- Kulicke and Soffa Industries, Inc.

- Dr. Tresky AG

- Fasford Technology Co Ltd.

- Inseto UK Limited

- Anza Technology Inc.

第7章 投資分析

第8章 市場機會及未來趨勢

The Die Attach Equipment Market size is estimated at USD 1.45 billion in 2024, and is expected to reach USD 1.95 billion by 2029, growing at a CAGR of 6.09% during the forecast period (2024-2029).

Growth is fueled by the increased use of stacked die technology in the Internet of Things (IoT) devices. In recent trends, the demand for hybrid circuits has remained strong due to emerging and existing applications in medical, military, photonics, wireless electronics, etc.

Key Highlights

- C2W hybrid bonding is a promising emerging technology that can enable direct Cu- Cu bonding and replace TCB for 3D stacked memory and high-end logic applications. However, C2W hybrid bonding is still in its early stages level. It is expected to hit the market in 2022/23 for logic devices with 2.5D structures, significantly assisting the equipment market's growth.

- The demand for the AuSn Eutectic Die-Attach technique drives the market. Traditionally, various die-attach products, which include metal-filled conductive epoxies, high lead-containing solders, and gold-silicon solders, were sufficient to mount the chip and have it perform reliably for the life of the device. However, the trend towards increasing heat generation, demand for compact devices, enactment of RoHS and REACH legislation, and the transition to GaAs chips limited the use of conventional materials. The demand for high device reliability has led engineers to evaluate various new materials for their die attachment.

- The suggested solder preforms are eutectic gold-tin and can be implemented for high volume or lab quantity adoption using a Palomar Technologies' die bonder. This equipment can handle the complete die-attach process, including high-accuracy pick-and-place of substrates, eutectic gold-tin preforms, and components; eutectic die-attach; and pulsed-heat reflow using a computer-controlled Pulse Heat Stage (PHS).

- The demand for discrete power devices drives the market. Copper clips are becoming increasingly popular as an alternative to traditional wire and ribbon bonding. Die-attach functionality is a feature of packaging solutions for discrete power components. The adoption of wide-bandgap semiconductor die technologies (SiC and GaN) brings new innovative packaging solutions, including silver sintering die-attach (materials include epoxy molding compounds and interconnection materials). The progressive transition from discrete SiC towards SiC modules in EV/HEV applications, the embedded-die packaged systems, and the integration of GaN devices in multichip systems are just a few examples of such a trend. This factor enhances the demand for the die attaches equipment for the discrete power devices.

- However, primarily dimensional changes during processing and service life and mechanical unbalance of moving parts during processing through equipment challenges the equipment's functionality which could restrain the market.

- Further, the impact of COVID-19 does not highly affect the demand for equipment. For instance, during the pandemic, Palomar Technologies announced that they got a request for manufacturing critical semiconductor components to address COVID-19. They saw an acceleration of orders of their 3880 Die Bonder equipment to assist in wireless communications and networking bandwidth, remote medicine, IoT in robotics, and video conferencing. This acceleration is similar for other market players. Hence, the demand for equipment has remained relatively high during the pandemic. This demand will continue to grow post-pandemic owing to the need for IoT devices, automation, and smart technologies.

Die Attach Equipment Market Trends

LED to Witness Significant Growth

- Die attach material is key in the performance and reliability of mid, high, and super-high power LEDs. The demand for die-attach equipment is increasing with an increasing LED penetration rate. The selection of suitable die-attach material for a particular chip structure and application depends on various considerations, which include the packaging process (throughput and yield), performance (thermal dissipation output and light output), reliability (lumen maintenance), and cost. Eutectic gold-tin, silver-filled epoxies, solder, silicones, and sintered materials have all been used for LED die attach.

- For instance, SFE provides an Epoxy Adhesive bonding method where its LED Epoxy Die Bonder machine features an index time of 0.2 Sec /Cycle (90 Percent Rate of Operation) with a chip size of 250 * 250 standards, providing lead frame recognition through 2 Cameras. Its software function provides auto mount level & pick-up level teaching functions.

- Further, conductive adhesives (mostly silver-filled epoxies) constitute LEDs' most extensive thermal die-attach materials (by unit number). They are compatible with existing back-end packaging equipment and provide an attractive cost/performance balance (typically up to 50 W/mK thermals with secondary reflow compatibility). As they stick to bare silicon, they are the most preferred material for dies without back-end metallization like GaN on silicon.

- Further, in the LED market, there are a lot of rivals or competitors, and ASM is one of the prominent players in this market, and its LED Epoxy High speed die bonder AD830 dominates in the LED market. As more and more countries are getting close to phasing out conventional bulbs, LEDs are continuing their march to the top of the market. According to Joint Research Center, The penetration rate of LEDs based on sales is raising and is expected to reach a penetration rate of 75.8 % by 2025. This factor enhances the demand for the die attaches equipment market.

- Furthermore, in September 2022, Palomar Technologies launched a new 3880-II die-bonder, which won the 2022 military+Aerospace electronics Innovation Award. This new machine includes options to maximize productivity, reduce programming time by up to 95% and improve overall bonder productivity.

Asia-Pacific Accounts for Significant Market Growth

- Asia-Pacific accounted for the significant growth of the die-attach equipment industry. More than 60% of OSAT (Outsourced Semiconductor Assembly And Test) players present across the world have their headquarters in the APAC region. These OSAT companies use die-attach equipment in the semiconductor fabrication process. Additionally, an increasing number of IDMs (Integrated Device Manufacturers) in the region is expected to boost the market growth shortly.

- In China and Taiwan, the mass production of electronic products, including smartphones, wearables, and white goods, uses several devices, such as optoelectronics, MEMS, and MOEMS. All these devices require die-attach equipment in the assembly process of these components.

- Further, South Korea, China, and mostly Japan's old age population are anticipated to accelerate the need for healthcare services during the forecast period, thus providing scope for devices, such as ventilators, dialysis, and blood pressure monitoring devices constituting MEMS pressure sensors. ESCAP estimates that the geriatric population in the region, aged 60 years and older, could penetrate at the rate of 10.64 by 2025 with 9.55 in the current year and raise to 18.44 by 2050, which represent 60 percent of the worlds population. The instance caters to the growth of the market due to the demand for die-attach equipment for MEMS pressure sensor.

- Furthermore, India is also witnessing growth in a number of smart cities, due to government initiatives and are expected to incorporate electronic solutions for purposes, such as surveillance, maintenance, monitoring, etc. According to smartcities.gov.in, the central government has allotted USD 977 million into the development of 60 such smart cities. This leads to the demand for a higher number of CMOS image sensors, which further supports the market growth.

- High Power lasers are finding extensive demand in industrial sectors for a wide range of applications, including cutting, welding, and fabrication. Companies are moving towards Laser technologies to take advantage of high performance and reliability. The advancement in laser diode significantly increases the demand for equipment, which processes the technique of Epoxy and Eutectic bonding.

- Further memory demand is expected to increase with the development of IoT, AI, and ADAS. As a result, productivity improvement in memory chip manufacturing and improvement of post-processing device reliability will be required more than in the past. To address this, in August 2022, Stanford engineers created a more efficient and flexible AI chip, which could bring the power of AI into tiny edge devices that contributes to improved throughput and reliability in memory production.

Die Attach Equipment Industry Overview

The die-attach equipment market is fragmented as the presence of local and global players penetrates the intense rivalry in the market. Further, players are focusing on improving their equipment performance in terms of throughput and yield through development and partnership, making the market more competitive. Key players are Be Semiconductor Industries N.V., ASM Pacific Technology Limited, Palomar Technologies Inc, etc. Recent developments in the market are -

- In October 2022, Hermetic Solutions Group (HSG) acquired the Intellectual property of DiaCool, from RHP Technologies. This expands HSG's product lineup and offers customers significantly more options for many years. HSG's DiaCool diamond composite material for heat sinks, die tabs, and heat spreaders provide customers with significant advantages over conventional laminate or MMC materials.

- In October 2022, Kulicke and Soffa received multiple new purchase orders for its thermo-compression solution and successfully shipped its first Fluxless Thermo-Compression Bonder (TCB) to a key customer and continues its position in the advanced LED Assembly.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Demand of AuSn Eutectic Die-Attach Technology

- 4.2.2 Demand of Discrete Power Devices

- 4.2.3 LED Segment to Witness Significant Growth

- 4.3 Market Restraints

- 4.3.1 Dimensional Changes During Processing and Service Life and Mechanical Unbalance

- 4.4 Industry Value Chain Analysis

- 4.5 Industry Attractiveness - Porter's Five Forces Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers/Consumers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

- 4.6 Assessment of Impact of COVID-19 on the Market

5 MARKET SEGMENTATION

- 5.1 Type

- 5.1.1 Die Bonder

- 5.1.2 Flip Chip Bonder

- 5.2 Bonding Technique

- 5.2.1 Epoxy

- 5.2.2 Eutectic

- 5.2.3 Soft Solder

- 5.2.4 Hybrid Bonding

- 5.2.5 Other Bonding Techniques

- 5.3 Application

- 5.3.1 Memory

- 5.3.2 RF & MEMS

- 5.3.3 LED

- 5.3.4 CMOS Image Sensor

- 5.3.5 Logic

- 5.3.6 Optoelectronics / Photonics

- 5.3.7 Other Applications

- 5.4 Geography

- 5.4.1 North America

- 5.4.2 Europe

- 5.4.3 Asia Pacific

- 5.4.4 Latin America

- 5.4.5 Middle East and Africa

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Palomar Technologies, Inc.

- 6.1.2 Shinkawa Ltd.

- 6.1.3 MicroAssembly Technologies, Ltd.

- 6.1.4 ASM Pacific Technology Limited

- 6.1.5 Be Semiconductor Industries N.V.

- 6.1.6 Kulicke and Soffa Industries, Inc.

- 6.1.7 Dr. Tresky AG

- 6.1.8 Fasford Technology Co Ltd.

- 6.1.9 Inseto UK Limited

- 6.1.10 Anza Technology Inc.