|

市場調查報告書

商品編碼

1429471

精製催化劑:市場佔有率分析、產業趨勢、成長預測(2024-2029)Refining Catalysts - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

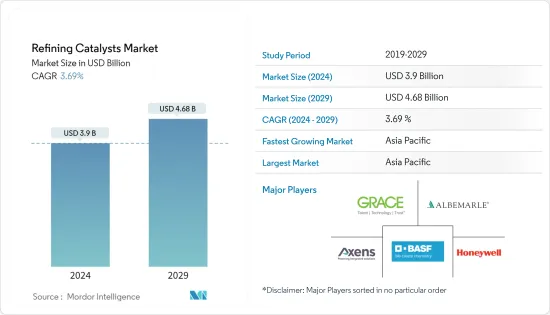

精製催化劑市場規模預計到 2024 年為 39 億美元,預計到 2029 年將達到 46.8 億美元,在預測期內(2024-2029 年)複合年成長率為 3.69%。

由於精製產品的消費減少,COVID-19 疫情對市場產生了負面影響。但2021年,產業復甦,市場需求恢復。

主要亮點

- 短期來看,煉油廠投資增加和高辛烷值燃料需求增加是推動市場的主要因素。

- 另一方面,貴金屬價格的波動預計將阻礙市場成長。

- 焦點轉向奈米催化劑似乎是未來的一個機會。

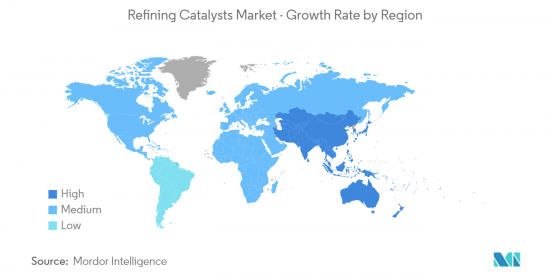

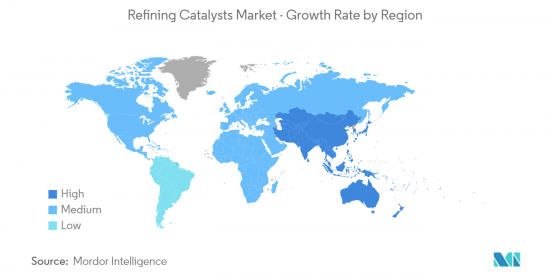

- 亞太地區是精製催化劑最大的市場,幾乎佔全球佔有率的一半。

精製催化劑市場趨勢

流體化媒裂(FCC)催化劑主導市場

- 流體化媒裂(FCC) 製程在從原油生產輕量產品的煉油廠中發揮重要作用。

- FCC設備將各種類型的原料,包括裂解瓦斯油、瓦斯油、脫瀝青瓦斯油和真空/常壓樹脂,轉化為更輕、更高價值的產品,如瓦斯油、噴射機燃料、液化石油氣、煤油和汽油。你。

- 原料在FCC設備中進行高溫、中壓加熱。同時,原料與催化劑接觸,將高沸點烴液體的長鏈分子分解成較小的分子,然後以蒸氣形式回收。

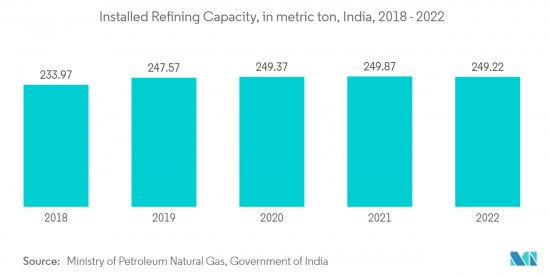

- 在 FCC 製程中,催化劑以細粉形式使用。先前,FCC設備中使用非晶質二氧化矽-氧化鋁等催化劑裂解減壓瓦斯油。然而,20 世紀 60 年代初沸石作為 FCC 催化劑的商業性應用標誌著催化裂解歷史上的重大突破。例如,印度石油公司(IOC)計劃斥資43.9億美元擴建其位於哈里亞納邦帕尼帕特的煉油廠。擴建計畫預計將於2024年9月完成,將使煉油廠的產量從每年1,500萬噸增加到2,500萬噸。

- 由於上述因素,FCC催化劑在預測期內對推動精製催化劑的市場需求非常重要。

亞太地區主導市場

- 亞太地區是石油精製催化劑最大的市場,幾乎佔全球佔有率的一半,也是成長最快的市場。

- 中國是主要市場佔有者,佔該地區的40%以上。中國精製能力佔世界精製能力的14%以上。

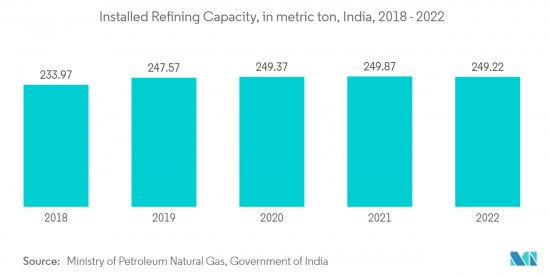

- 此外,印度最大的精製之一印度石油公司計劃在未來五到七年內投資229.1億美元(其中76.4億美元)擴建其現有的棕地煉油廠。

- 在韓國,由於乙烯工廠產能增加以及亞洲塑膠需求增加,預計石腦油用量將持續擴大。例如,韓國2022年燃料油產量約13.6億公升,較2021年成長28.55%。近年來,韓國燃料油產量增加。因此,該國燃料產量的增加預計將導致精製催化劑市場需求的增加。

- 此外,印尼正在加快計劃,幾乎提高其精製能力,以盡量減少對進口石油產品的依賴。政府希望在 2030 年將國內石油產量增加到 100 萬桶/日。這將需要鼓勵額外的研究和投資來改善老化油田的採收方法。

- 上述因素預計將在預測期內推動該國煉油精製市場的發展。

精製催化劑產業概況

精製催化劑市場因其性質而部分整合。該市場的主要企業包括(排名不分先後)WR Grace &Co.-Conn、Albemarle Corporation、 BASF SE、Axens 和 Honeywell International。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 調查先決條件

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 促進因素

- 對高辛烷值燃料的需求加速成長

- 擴大石油和天然氣活動

- 其他司機

- 抑制因素

- 貴金屬價格波動

- 其他阻礙因素

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章市場區隔(市場規模、金額/數量)

- 產品

- CoMo

- 鎳鉬

- 氧化鋁貴金屬

- NiW

- 沸石

- 其他產品

- 過程

- 加氫處理

- 汽油

- 煤油

- 柴油引擎

- 真空瓦斯油

- 催化裂解汽油

- 剩餘飼料

- 流體化媒裂(FCC)

- 渣油催化裂解(RFCC)

- 加氫裂解

- 加氫處理

- 地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 東南亞國協

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 西班牙

- 俄羅斯

- 歐洲其他地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東/非洲

- 沙烏地阿拉伯

- 南非

- 其他中東/非洲

- 亞太地區

第6章 競爭形勢

- 併購、合資、聯盟、協議

- 市場佔有率(%)**/排名分析

- 主要企業策略

- 公司簡介

- Albemarle Corporation

- Axens

- BASF SE

- China Petrochemical Corporation

- Exxon Mobil Corporation

- Topsoe

- Honeywell International

- JGC C & C

- Johnson Matthey

- Royal Dutch Shell PLC

- WR Grace & Co.-Conn

- Chevron Lummus Global(CLG)

- KNT Group

第7章 市場機會及未來趨勢

- OPEC國家未來投資與產能擴張

- 其他機會

The Refining Catalysts Market size is estimated at USD 3.9 billion in 2024, and is expected to reach USD 4.68 billion by 2029, growing at a CAGR of 3.69% during the forecast period (2024-2029).

The COVID-19 outbreak negatively impacted the market due to reduced consumption of oil-refined products. However, the industry witnessed a recovery in 2021, thus rebounding the demand for the market studied.

Key Highlights

- Over the short term, increasing investment in refineries and the accelerating demand for higher octane fuel are the major factors driving the market studied.

- On the flip side, the volatility in precious metal prices is expected to hinder market growth.

- The shifting focus toward nanocatalysts will likely act as an opportunity in the future.

- Asia-Pacific region accounted for the largest market for refining catalysts, with almost half of the global share, and is also expected to be the fastest-growing market.

Refining Catalysts Market Trends

Fluid Catalytic Cracking (FCC) Catalysts to Dominate the Market

- The fluid catalytic cracking (FCC) process plays a crucial role in refineries while producing lighter products from crude oil.

- FCC unit helps in converting a variety of feed types, such as cracked gas oil, gas oil, deasphalted gas oils, vacuum/atmospheric resins, and others, into lighter and high-value products, such as diesel oil, jet fuel, LPG, kerosene, and gasoline.

- The feedstock is heated at high temperatures and moderate pressure in the FCC unit. Along with this, the feedstock is brought in contact with a catalyst which helps break the long-chain molecules of the high-boiling hydrocarbon liquids into small molecules, which are further collected as vapors.

- In the FCC process, the catalysts are used as fine powders. Previously, catalysts, such as amorphous silica-alumina, were used for cracking vacuum gas oils in the FCC unit. However, in the early 1960s, zeolite was commercially introduced as an FCC catalyst, a significant advancement in the history of catalytic cracking. For instance, the Indian Oil Corporation (IOC) intends to spend USD 4.39 billion on expanding its oil refinery in Panipat, Haryana. The extension scheme, which is expected to be completed by September 2024, will expand the refinery's production from 15 million tons annually to 25 million tons annually.

- Due to the abovementioned factors, FCC catalysts are important in propelling the market demand for refining catalysts in the forecast period.

Asia-Pacific to Dominate the Market

- Asia-Pacific region accounted for the largest market for refining catalysts, with almost half of the global share, and is also expected to be the fastest-growing market.

- China is the primary market holder, accounting for more than 40% of the region. China's refinery capacity accounts for over 14% of the world's refining capacity.

- Additionally, one of the top oil refiners in India, Indian Oil Corp, plans to invest USD 22.91 billion, including USD 7.64 billion, for expanding its existing brownfield refineries in the next 5 to 7 years.

- Naphtha use will likely continue expanding in South Korea due to capacity additions at ethylene plants and the rising demand for plastics in Asia. For instance, in 2022, the production volume of fuel oil in South Korea amounted to around 1.36 billion liters, which shows an increase of 28.55% compared to 2021. Fuel oil production in South Korea has risen in recent years. Therefore, increasing the production volume of fuel in the country is expected to create an upside demand for the refining catalysts market.

- Moreover, Indonesia is speeding up plans to nearly increase its oil refining capacity to minimize its reliance on imported petroleum products. By 2030, the government wants to increase domestic petroleum output to 1 million bpd. It seeks to do this by stimulating additional research and investment in improved recovery procedures for aging fields.

- All the factors above, in turn, are expected to drive the market for refining catalysts in the country during the forecast period.

Refining Catalysts Industry Overview

The refining catalysts market is partially consolidated in nature. The major players in this market include (not in any particular order) W. R. Grace & Co.-Conn, Albemarle Corporation, BASF SE, Axens, and Honeywell International, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Accelerating Demand for Higher-Octane Fuel

- 4.1.2 Expansion of Oil and Gas Activities

- 4.1.3 Other Drivers

- 4.2 Restraints

- 4.2.1 Volatility in Precious Metal Prices

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value and Volume)

- 5.1 Product

- 5.1.1 CoMo

- 5.1.2 NiMo

- 5.1.3 Alumina-based Noble Metal

- 5.1.4 NiW

- 5.1.5 Zeolites

- 5.1.6 Other Products

- 5.2 Process

- 5.2.1 Hydrotreating

- 5.2.1.1 Gasoline

- 5.2.1.2 Kerosene

- 5.2.1.3 Diesel

- 5.2.1.4 Vacuum Gas Oil

- 5.2.1.5 Catalytic Cracking Gasoline

- 5.2.1.6 Residual Feed

- 5.2.2 Fluid Catalytic Cracking (FCC)

- 5.2.3 Residue Fluid Catalytic Cracking (RFCC)

- 5.2.4 Hydrocracking

- 5.2.1 Hydrotreating

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN Countries

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Spain

- 5.3.3.6 Russia

- 5.3.3.7 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Albemarle Corporation

- 6.4.2 Axens

- 6.4.3 BASF SE

- 6.4.4 China Petrochemical Corporation

- 6.4.5 Exxon Mobil Corporation

- 6.4.6 Topsoe

- 6.4.7 Honeywell International

- 6.4.8 JGC C & C

- 6.4.9 Johnson Matthey

- 6.4.10 Royal Dutch Shell PLC

- 6.4.11 W. R. Grace & Co.-Conn

- 6.4.12 Chevron Lummus Global (CLG)

- 6.4.13 KNT Group

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Upcoming Investments and Capacity Additions in OPEC Countries

- 7.2 Other Opportunities