|

市場調查報告書

商品編碼

1406130

貨櫃裝卸設備-市場佔有率分析、產業趨勢與統計、2024年至2029年成長預測Container Handling Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029 |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

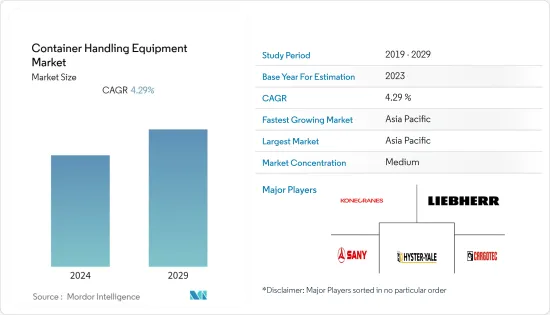

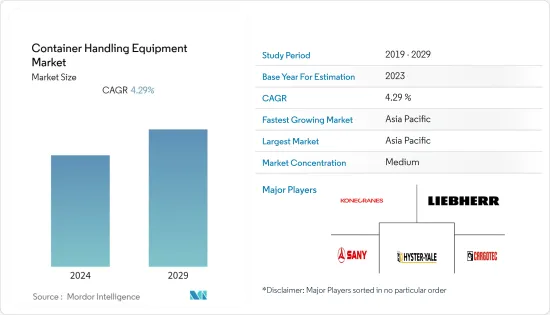

貨櫃裝卸設備市場目前價值 73.4 億美元,預計未來五年將成長至 94.3 億美元,預測期內收益複合年成長率為 4.29%。

從中期來看,國際商業的擴張和貨運需求的成長決定了近幾十年來全球經濟的發展。由於全球化和工業化,中國和印度等亞太國家預計將保持最高的成長率,因為它們擁有涉及大規模進出口的大型製造設施。

港口碼頭自動化趨勢的變化、電子商務產業的興起,以及對電氣和混合設備的需求不斷成長,重點是生產現場的勞動力預防措施和嚴格的排放法規,正在推動貨櫃裝卸設備市場的發展。創新的商業機會。

港口碼頭自動化趨勢的變化、電子商務行業的成長以及對電動和混合設備的需求不斷增加,重點關注工人安全和生產現場嚴格的排放標準,推動了貨櫃裝卸設備市場的發展。和創新的商業機會。

貨櫃貨物裝卸設備市場趨勢

越來越重視貨櫃裝卸設備的電動

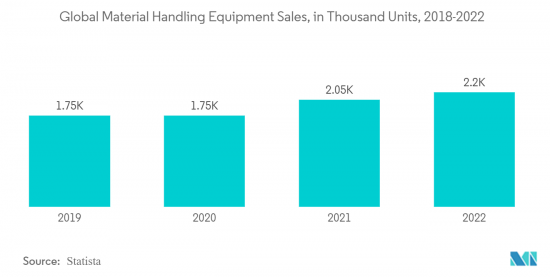

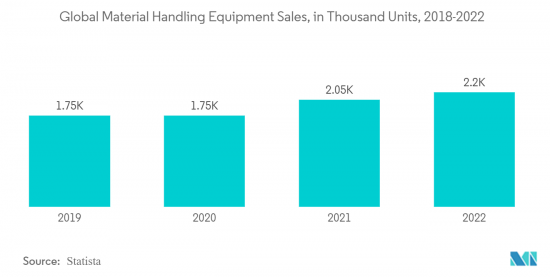

全球經濟成長和工業化程度不斷提高正在推動各行業對貨櫃裝卸設備的需求。銷售成長的原因是其應用範圍廣泛,包括建設業、製造業、港口貨物裝卸業等。

推動搬運設備銷售的另一個因素是電子商務、零售和物流行業的快速擴張,特別是在印度、巴西、新加坡和墨西哥等新興經濟體。

生態效率對於貨物和材料處理變得極為重要。隨著世界各地的港口和碼頭不斷提高能源效率和減少排放,電動是席捲整個產業的最新趨勢。事實證明,港口設施電氣化可以顯著減少排放氣體。隨著各國注重減少排放,預計未來幾年電動和混合電動貨櫃的採用將會增加。

此外,一些電子商務公司正在部署新策略來縮短交貨時間,例如大力投資自動堆高機和電動堆高機,以加快裝載和提貨的過程。隨著世界各地對柴油車實施更嚴格的排放法規以控制二氧化碳排放,製造商現在正在提供更環保的堆高機型號。此外,政府在這方面的舉措將在預測期內提振市場需求。

更嚴格的排放法規可能會要求貨櫃裝卸設備製造商在不犧牲其電力能力的情況下提高其產品的能源效率。根據美國環保署(EPA)新的越野車輛/設備(包括建築、農業採礦和物料搬運設備)排放標準,所有新購買的堆場卡車和帶入港口或聯運鐵路堆場的非堆場卡車設備必須配備Tier 4 Final 越野引擎或車型年份(MY) 2010 或更高版本的公路式引擎。因此,製造商逐漸在新型貨櫃裝卸機械中採用 Tier 4 引擎技術。

堆高機技術的進步使倉庫環境對每個人來說都更加安全。例如,可以透過使其更容易快速轉向來降低堆高機事故的可能性。工人不會因受傷而失去工作,生產力也保持不變。此外,較低的事故率意味著更少的堆高機維修。

由於上述全球發展,預計在預測期內對貨櫃裝卸設備的需求將會成長。

亞太地區仍維持市場領先地位

亞太地區由中國、印度等全球主要新興經濟體組成,對原料及最終產品的需求量較大,貨櫃進出口量較大。

中國是亞太地區主要國家之一,擁有經濟成長支撐的最活躍的工業活動。中國有34個貨櫃港口和2000個小港口。上海是世界上最大的港口,運輸能力達4,330萬個標準箱。

該國的成長率很高,但逐漸放緩(隨著人口老化和經濟從投資轉向消費、從製造業轉向服務業、從外需轉向內需的再平衡)。然而,由於中國人事費用和材料成本較低,許多企業在中國生產產品,然後出口到所需目的地。結果,中國已成為世界主要出口國之一。

近年來,中國港口建設取得長足發展,全球貨運量和貨櫃吞吐量前10名的港口中有7個位於中國。作為上海港的主港,洋山深水港規模龐大,貨櫃吞吐量至少佔總貨櫃吞吐量的40%。隨著四期工程的啟用,上海港年貨櫃吞吐量將超過4000萬標準箱,總合美國所有港口年貨櫃吞吐量的總和。

印度是亞太地區主要國家之一,其進出口活動受到其經濟成長的支持。孟買港是全國最大、最繁忙的港口。

據港口、航運和水道部稱,印度最繁忙的國營貨櫃門戶賈瓦哈拉爾·尼赫魯港務局 (JNPA) 處理了 4,177,000 標準箱,高於去年同期的 3,222,000 標準箱。

日本有許多主要的貨物裝卸設備製造商,當地企業壟斷了港口貨物裝卸設備的設計和製造。他們還有自己的設計、製造和品質標準。因此,其他國家的產品要進入日本市場需要付出很大的努力。

日本正面臨人口老化和人口減少的挑戰,這就是為什麼公司正在投資開發碼頭和貨櫃裝卸自動化等先進技術,以提高生產力和安全性。此外,為了降低貨櫃裝卸設備的營運成本,人們已經開始採用最新技術對舊設備進行改造。通力起重機和卡爾瑪是為舊設備提供改造服務的眾多公司中的兩家。這包括舊設備的自動化。

隨著上述開拓在全部區域的發生,市場可能會在預測期內顯著成長。

貨櫃裝卸設備產業概況

幾家主要企業主導著貨櫃裝卸設備市場,包括卡哥特科公司、利勃海爾集團、三一集團、海斯特-耶魯物料搬運公司和科尼集團。本公司大力投資於新的和先進的產品創新的研發。全球製造設施的擴張預計將在未來幾年提振市場。例如

- 2023年9月,環球港口在東方港裝卸公司(VSC)的遠東碼頭安裝了設備。本公司與上海振華重工(ZPMC)簽署採購港口貨櫃裝卸設備的合作備忘錄。

- 2022年10月,豐田物料搬運在北美推出更新版豐田三輪電動堆高機。這款新型電動堆高機為其細分市場中最暢銷的堆高機帶來了新功能和技術。

- 2022 年 1 月,卡哥特科旗下卡爾瑪與 Westport AS 簽署協議,在挪威提供世界上第一台配備組合充電系統的電動正面堆垛機。該訂單還包括一份為期五年的卡爾瑪全面保養服務契約,該合約將累計入卡哥特科的 2022 年第一季訂單,併計劃於 2022 年第四季度初交貨。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 調查先決條件

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 市場促進因素

- 越來越重視貨櫃裝卸設備的電動

- 市場抑制因素

- 貨櫃裝卸設備的資金成本高且複雜

- 波特五力分析

- 供應商的議價能力

- 買家/消費者的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間敵對關係的強度

第5章市場區隔(市場規模)

- 依設備類型

- 堆高機

- 堆疊起重機

- 移動式港口起重機

- 膠輪高架起重機

- 依推進類型

- 柴油引擎

- 電動式

- 混合

- 按地區

- 北美洲

- 美國

- 加拿大

- 北美其他地區

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 歐洲其他地區

- 亞太地區

- 印度

- 中國

- 日本

- 韓國

- 其他亞太地區

- 世界其他地區

- 南美洲

- 中東/非洲

- 北美洲

第6章 競爭形勢

- 供應商市場佔有率

- 公司簡介

- Cargotec Corp.

- Liebherr Group

- SANY Group

- Shanghai Zhenhua Heavy Industries Co. Ltd(ZPMC)

- Hyster-Yale Materials Handling Inc.

- Anhui HELI Forklifts Group Co. Ltd

- Hoist Material Handling Inc.

- CVS Ferrari SpA

- Lonking Holdings Limited

- Konecranes

第7章 市場機會及未來趨勢

The Container Handling Equipment Market is valued at USD 7.34 billion in the current year and is expected to grow to USD 9.43 billion by the next five years, registering a CAGR of 4.29% in terms of revenue during the forecast period.

Over the medium term, the expansion of international commerce and the rising need for cargo transportation defined global economic development in recent decades. Due to large-scale manufacturing facilities involved in large-scale imports and exports, Asia-Pacific nations such as China and India are predicted to include the highest growth rates as a result of globalization and industrialization.

The shifting trends toward automation of port terminals, the rising e-commerce industry, and growing requirements for electric and hybrid equipment, with emphasis on precaution for labor on the production floor and stringent emission norms, provide innovative business opportunities in the container handling equipment market.

The container handling equipment market may see innovative new opportunities as a result of shifting trends toward port terminal automation, the growing e-commerce industry, and growing demands for electric and hybrid equipment, with an emphasis on worker safety on the production floor and stringent emission standards.

Container Handling Equipment Market Trends

Growing Emphasis on the Electrification of Container Handling Equipment

The growing world economy and rising industrialization are driving the demand for container-handling equipment across different fields. Their use in industries like construction, manufacturing, and port handling, owing to the wide range of applications, are the reasons for their increased sales.

Another factor boosting the handling equipment sales is the rapid expansion of the e-commerce, retail, and logistics industries, especially in developing economies such as India, Brazil, Singapore, and Mexico.

Eco-efficiency became extremely important for cargo and material handling. As ports and terminals around the world move toward improved energy efficiency and reduced emissions, electrification is the latest trend sweeping across the industry. Electrification of port equipment proved to reduce emissions hugely. With countries focusing on reducing their emissions, the adoption of electric and hybrid-electric containers is expected to increase in the years to come.

In addition, some e-commerce companies are developing new strategies, including investing heavily in autonomous and electric forklifts to speed up the loading and picking up processes of products as they reduce the delivery time. Stringent emission norms for diesel vehicles across the globe to regulate CO2 emissions led the manufacturers to offer more environment-friendly forklift truck models. Furthermore, government initiatives in this regard boost demand in the market over the forecast period.

More stringent emission regulations may require manufacturers of container handling equipment to improve the energy efficiency of their products without sacrificing their power capabilities. According to the new emission standards for off-road vehicles/equipment (including construction, agricultural mining, and material handling equipment) by the Environmental Protection Agency (EPA), all newly purchased yard truck and non-yard truck equipment brought onto a port or intermodal rail yard must include either a Tier 4 final off-road engine or a model year (MY) 2010 or newer on-road engine. Thus, Tier 4 engine technology is gradually adopted by manufacturers in their new container handling equipment.

Forklift technology advancements make warehouse environments safer for everyone. For instance, reducing the likelihood of forklift accidents can be achieved by making it simpler to make a fast turn. Workers won't get hurt and lose their jobs, and productivity rates can stay the same. Additionally, fewer forklift repairs are required when accident rates drop.

With the development mentioned above across the globe, the demand for container handling equipment is likely to grow during the forecast period.

Asia-Pacific Remains the Market Leader

The Asia-Pacific region consists of major developing economies of the world, such as China and India, where a large volume of containers is exported and imported due to the high requirement for raw materials and final products.

China is one of the major countries in the Asia-Pacific region, with the highest industrial activities being supported by its growing economy. China includes 34 container ports and 2,000 minor ports. Shanghai is the world's largest port, with a capacity of 43.3 million TEU.

The country's growth rate is high but is gradually moving toward moderate (as the population ages and the economy rebalances from investment to consumption, manufacturing to services, and external to internal demand). However, due to low labor and material costs in China, many companies manufacture their products in China and later export them to required destinations. It helped China position itself as the world's leading exporter.

China's port construction developed so greatly in recent years that seven of the world's top 10 ports, in terms of both cargo and container throughput, are in China. As a major part of Shanghai Port, Yangshan Port boasts of a big container throughput, which accounts for at least 40% of the total. The opening of the fourth phase will help the annual container throughput in Shanghai Port surpass 40 million TEUs, which is equivalent to the sum of all US ports' annual container throughput.

India is one of the major countries in the Asia-Pacific region, with import and export activities being supported by its growing economy. Mumbai Port is the country's largest and busiest port.

According to the Ministry of Ports, Shipping and Waterways, India's busiest state-run container gateway, Jawaharlal Nehru Port Authority (JNPA), handled 4.177 million TEUs, up from 3.222 million TEUs during the same time previous year.

Japan contains many of the leading cargo-handling machinery manufacturers, and the local companies made the monopoly on designing and manufacturing the cargo handling equipment for ports in Japan. They had unique standards for design, manufacturing, and quality. Thus, it took a lot of work for the products of other countries to enter the market of Japan.

Japan is facing the problem of aging and decreasing population, which is the reason why companies are investing in the development of advanced technologies such as terminal container handling automation to improve productivity and safety. They also started to retrofit old equipment with the latest technology to reduce the operational costs of container handling equipment. Kone Cranes and Kalmar are two of many companies that provide retrofitting services for old equipment. It includes old equipment automation as well.

The development mentioned above across the region is likely to witness major growth for the market during the forecast period.

Container Handling Equipment Industry Overview

Several key players, such as Cargotec Corp, Liebherr Group, SANY Group, Hyster-Yale Materials Handling Inc., Konecranes, and others, dominate the container handling equipment market. Companies are investing heavily in research and development for the innovation of new and advanced products. The expansion of manufacturing facilities across the globe is anticipated to boost the market in the coming years. For instance,

- In September 2023, Global Ports equipped the Far Eastern terminal of Vostochnaya Stevedoring Company (VSC). They signed a memorandum of intent with Shanghai Zhenhua Heavy Industry Company (ZPMC) to buy portside container handling equipment.

- In October 2022, Toyota Material Handling launched an updated version of Toyota's 3-Wheel Electric Forklift in North America. The new updated electric forklift equipped with new features and technology to the top-selling forklift in the segment.

- In January 2022, Kalmar, part of Cargotec, agreed with Westport AS to supply the world's first electric reach stacker with a combined charging system in Norway. The order also includes a five-year Kalmar Complete Care service agreement, which was booked in Cargotec's Q1 2022 order intake, with delivery scheduled for early Q4 of 2022.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Drivers

- 4.1.1 Growing Emphasis on The Electrification of Container Handling Equipment

- 4.2 Market Restraints

- 4.2.1 High Capital Cost And Increasing Complexity of Container Handling Equipment

- 4.3 Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers/Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION (Market Size in Value (USD))

- 5.1 By Equipment Type

- 5.1.1 Forklift Truck

- 5.1.2 Stacking Crane

- 5.1.3 Mobile Harbor Crane

- 5.1.4 Rubber-tired Gantry Crane

- 5.2 By Propulsion Type

- 5.2.1 Diesel

- 5.2.2 Electric

- 5.2.3 Hybrid

- 5.3 By Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Rest of North America

- 5.3.2 Europe

- 5.3.2.1 Germany

- 5.3.2.2 United Kingdom

- 5.3.2.3 France

- 5.3.2.4 Italy

- 5.3.2.5 Spain

- 5.3.2.6 Rest of Europe

- 5.3.3 Asia-Pacific

- 5.3.3.1 India

- 5.3.3.2 China

- 5.3.3.3 Japan

- 5.3.3.4 South Korea

- 5.3.3.5 Rest of Asia-Pacific

- 5.3.4 Rest of the World

- 5.3.4.1 south America

- 5.3.4.2 Middle-East and Africa

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Vendor Market Share

- 6.2 Company Profiles*

- 6.2.1 Cargotec Corp.

- 6.2.2 Liebherr Group

- 6.2.3 SANY Group

- 6.2.4 Shanghai Zhenhua Heavy Industries Co. Ltd (ZPMC)

- 6.2.5 Hyster-Yale Materials Handling Inc.

- 6.2.6 Anhui HELI Forklifts Group Co. Ltd

- 6.2.7 Hoist Material Handling Inc.

- 6.2.8 CVS Ferrari SpA

- 6.2.9 Lonking Holdings Limited

- 6.2.10 Konecranes