|

市場調查報告書

商品編碼

1404505

氣體感測器、氣體偵測、氣體分析儀:市場佔有率分析、產業趨勢與統計、成長預測,2024-2029Gas Sensor, Detector and Analyzer - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029 |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

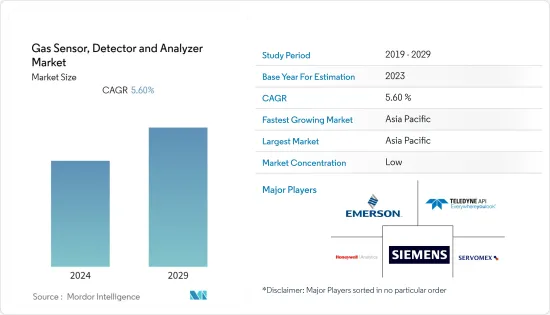

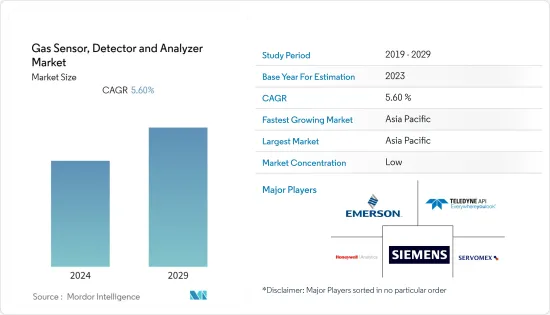

今年氣體感測器、氣體偵測和氣體分析儀市值為46.7億美元,預計未來五年將以5.6%的複合年成長率成長,達到61.3億美元。

氣體感測器是化學感測器,可以測量其附近的成分氣體的濃度。這些感測器包含多種用於精確量化介質氣體含量的技術。氣體偵測使用其他技術測量和顯示空氣中特定氣體的濃度。氣體偵測的特點是它們可以在環境中偵測的氣體類型。氣體分析儀廣泛應用於多個終端用戶產業的安全設備整體,以維持職場的足夠安全。

主要亮點

- 頁岩氣和緻密油的發現不斷增加,推動了全球對氣體分析儀的需求。政府立法和職業安全與健康法規的執行也強制在某些工業環境中使用氣體分析儀。社會對氣體洩漏和廢氣危險的認知不斷提高,也促進了氣體分析儀的普及。製造商正在將氣體分析儀與行動電話和其他無線設備整合,以提供即時監控、遠端控制和資料備份。

- 氣體洩漏和其他意外污染可能導致爆炸後果、人身傷害和火災危險。在密閉空間中,許多危險氣體甚至會取代氧氣而導致附近工人窒息。這些後果威脅著員工、設備和財產的安全。

- 手持式氣體偵測工具透過監測使用者靜止和移動時的呼吸區域來確保工人的安全。這些設備在許多可能存在氣體危險的情況下至關重要。空氣中氧氣、易燃物和有毒氣體的監測對於確保每個人的安全至關重要。手持式氣體偵測具有內建警報器,可提醒工作人員注意密閉空間等應用中的潛在危險情況。當觸發警報時,易於讀取的大型液晶顯示器會確認有害氣體或氣體濃度。

- 近年來,由於技術創新,氣體感測器和偵測的製造成本穩步上升。雖然市場現有企業已經能夠適應這些變化,但新參與企業和中型製造商面臨重大挑戰。

- 由於新冠肺炎 (COVID-19) 疫情的爆發,受訪市場中的多個最終用戶行業都受到了營運減少和工廠臨時關閉的影響。例如,在可再生能源產業,全球供應鏈是一個主要問題,生產大幅放緩,新測量系統和感測器的支出減少。硫化氫 (H2S) 和二氧化碳 (CO2) 的檢測和監測在天然氣加工中非常重要,因此對氣體分析儀產生了大量需求。

氣體感測器、氣體偵測和氣體分析儀的市場趨勢

石油和天然氣產業預計將佔據主要市場佔有率

- 在石油和天然氣行業,保護加壓管道免受腐蝕和洩漏並最大限度地減少停機時間是一項重要責任。根據NACE(美國腐蝕工程師協會)的研究,石油和天然氣生產行業每年因腐蝕造成的總成本約為13.72億美元。

- 氣體樣品中是否有氧氣可確定加壓管路系統是否有洩漏。連續且未被發現的洩漏會使情況惡化,同時影響管道的運作流量效率。此外,管道系統中硫化氫 (H2S) 和二氧化碳 (CO2) 等氣體的存在會產生腐蝕性和破壞性混合物,與氧氣反應並結合,從內部劣化管道壁。

- 降低這些高成本是業界採用氣體分析儀進行預防措施的動力之一。氣體分析儀透過有效檢測此類氣體的存在來幫助監控洩漏,從而延長管道系統的使用壽命。石油和天然氣產業正在轉向 TDL 技術(可調諧二極體雷射),該技術可實現高解析度偵測可靠性並避免傳統分析儀的常見干擾。

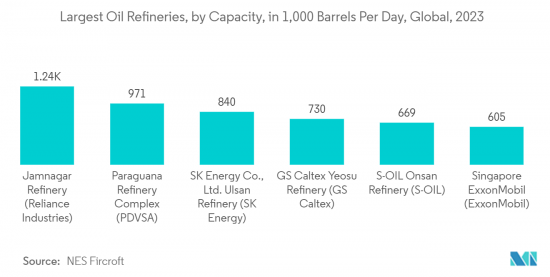

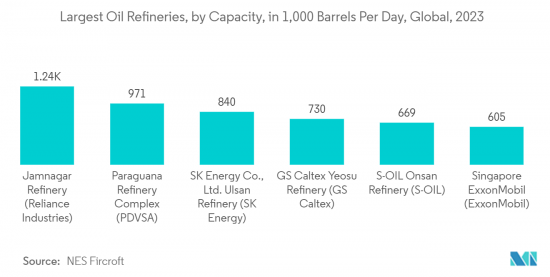

- 根據國際能源總署 (IEA) 2022 年 6 月的公告,全球淨精製能力預計將在 2022 年增加 100 萬桶/日,並在 2023 年進一步增加 160 萬桶/日。這些趨勢預計將進一步推動市場需求,因為煉廠氣體分析儀通常用於表徵原油精製過程中產生的氣體。

- 據 IEA 稱,2021 年全球天然氣供應量預計將增加 4.1%,部分原因是 COVID-19 大流行後市場復甦。硫化氫 (H2S) 和二氧化碳 (CO2) 的檢測和監測在天然氣加工中非常重要,因此對氣體分析儀產生了大量需求。

亞太地區預計將佔據主要市場佔有率

- 石油和天然氣、鋼鐵、電力、化學品和石化領域新工廠投資的增加以及國際安全標準和實踐的採用增加預計將影響市場成長。亞太地區是近年來唯一一個油氣產能成長的地區。該地區新建了大約四家煉油廠,使全球原油產量增加近 75 萬桶/日。

- 由於石油和天然氣行業中用於製程監控、提高安全性、提高效率和提高品質的應用,該地區的工業發展正在推動氣體分析儀的成長。因此,該地區的煉油廠正在將氣體分析儀引入其工廠。

- 預計亞太地區將成為預測期內全球氣體感測器市場成長最快的地區之一。這是由於嚴格的政府法規的加強和持續的環保意識提升宣傳活動。此外,根據 IBEF 的數據,根據 2019-25 年國家基礎設施管道,能源產業計劃在預計資本支出總額 1.11 億印度盧比(1.4 兆美元)中所佔比例最高(24%)。

- 該地區最近政府監管也大幅加強。此外,政府對智慧城市計劃的投資激增可能為智慧感測器設備創造巨大潛力,並推動該地區氣體感測器市場的成長。

- 亞太地區各國的快速工業化是推動氣體偵測市場成長的主要因素之一。煙、霾和有毒氣體排放是由火電廠、煤礦、海綿鐵、鋼鐵、鐵合金、石油和化學等高污染行業產生的。氣體偵測通常用於偵測可燃性氣體、易燃、有毒氣體,確保工業操作安全。

氣體感測器/氣體偵測/氣體分析儀產業概況

氣體感測器、氣體偵測和氣體分析儀市場分散,因為世界各地有許多參與者。目前,有幾家知名公司正在開發以檢測器為中心的應用產品。分析儀部分應用廣泛,包括臨床測試、環境排放控制、爆炸物檢測、農業儲存、出貨和職場危險監測。市場參與者正在採取合作、合併、擴張、創新、投資和收購等策略來增強其產品供應並獲得永續的競爭優勢。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間的敵對關係

- 產業價值鏈分析

- 歐洲主要發電、輸電及配電公司

- 歐洲氫價值鏈

- 歐洲主要產氫國

- 歐洲氫工業相關人員

- 評估 COVID-19 對產業的影響

第5章市場動態

- 市場促進因素

- 提高職業事故安全意識

- 手持設備的普及

- 市場抑制因素

- 高成本、產品缺乏差異化

第6章市場區隔

- 氣體分析儀

- 科技

- 電化學

- 順磁性的

- 氧化鋯

- 無損紅外線

- 最終用戶產業

- 油和氣

- 化學/石化

- 水/污水

- 製藥

- 其他

- 地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東/非洲

- 科技

- 氣體感測器

- 類型

- 毒性

- 電化學

- 半導體

- 光電離

- 易燃

- 催化劑

- 紅外線的

- 最終用戶產業

- 油和氣

- 化學/石化

- 水/污水

- 金屬/礦業

- 公用事業

- 其他

- 地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東/非洲

- 類型

- 氣體偵測

- 通訊類型

- 有線

- 無線的

- 偵測類型

- 固定的

- 攜帶的

- 最終用戶產業

- 油和氣

- 化學/石化

- 水/污水

- 金屬/礦業

- 公用事業

- 其他

- 地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東/非洲

- 通訊類型

第7章競爭形勢

- 公司簡介

- Emerson Electric Company

- Teledyne API

- Siemens AG

- Servomex Group Limited(Spectris PLC)

- Honeywell Analytics Inc.

- Draegerwerk AG & Co KGaA

- Industrial Scientific Corporation

- MSA Safety Incorporated

- Crowncon Detection Instruments Limited

- Yokogawa Electric Corporation

- Control Instruments Corporation

- Membrapor AG

- Senseir AB

- Eaton Corporation PLC

- GfG Gas Detection UK Ltd

- Figaro Engineering Inc.

- Robert Bosch GmbH

- Thermofisher Scientific Inc.

- Detector Electronics Corporation

- Alphasense Limited

- California Analytical Instruments

- Testo SE & Co. KGaA

- Trolex Ltd

- Bacharach Inc.

- MKS Instruments Inc.

- RKI Instruments Inc.

- Horiba Ltd

- SGX Sensortech Limited(Amphenol Limited)

- Afriso-Euro-Index GmbH

- General Electric Company

- NGK Spark Plugs USA Inc.

- Delphi Technologies(BorgWarner Inc.)

- Denso Corporation

- 供應商市場佔有率分析

第8章投資分析

第9章市場機會與未來成長

The Gas Sensor, Detector and Analyzer Market was valued at USD 4.67 billion the current year and is expected to grow at a CAGR of 5.6%, reaching USD 6.13 billion by the next five years. Gas sensors are chemical sensors that can measure the concentration of a constituent gas in its vicinity. These sensors embrace different techniques for quantifying a medium's exact amount of gas. A gas detector measures and indicates the concentration of certain gases in the air via other technologies. These are characterized by the type of gases they can detect in the environment. Gas analyzers find applications across safety instruments used in multiple end-user industries to maintain adequate safety in the workplace.

Key Highlights

- The global demand for gas analyzers has been boosted by an increase in shale gas and tight oil discoveries since these resources are utilized to stop corrosion in the infrastructure of natural gas pipelines. The use of gas analyzers has also been enforced in several industrial settings by government law and the enforcement of occupational health and safety rules. The growing public consciousness of the dangers of gas leaks and emissions contributed to the increased adoption of gas analyzers. Manufacturers are integrating gas analyzers with mobile phones and other wireless devices to offer real-time monitoring, remote control, and data backup.

- Gas leaks and other unintentional contamination can result in explosive consequences, physical harm, and fire risk. In confined spaces, numerous hazardous gases can even asphyxiate workers in the vicinity by displacing oxygen, which results in death. These outcomes jeopardize employee safety and the safety of equipment and property.

- Handheld gas detection tools keep personnel safe by monitoring a user's breathing zone while stationary and moving. These devices are critical in many situations where gas risks may exist. It is essential to monitor the air for oxygen, combustibles, and poisonous gases to ensure the safety of all people. Handheld gas detectors include built-in sirens that alert workers to potentially hazardous situations within an application, such as a confined space. When an alert is triggered, a large, easy-to-read LCD verifies the concentration of dangerous gas or gases.

- The production costs for gas sensors and detectors have steadily risen due to recent technological changes. While the market incumbents have been able to adapt to these changes, new entrants and mid-range manufacturers face considerable challenges.

- With the onset of COVID-19, multiple end-user industries in the market studied have been affected by reduced operations, temporary factory closures, etc. For instance, in the renewable energy industry, significant concerns revolve around global supply chains, which are considerably slowing down production, thus, aiming at reduced spending for new measurement systems and sensors. The detection and monitoring of hydrogen sulfide (H2S) and carbon dioxide (CO2) is pertinent in natural gas processing, creating significant demand for gas analyzers.

Gas Sensor, Detector, and Analyzer Market Trends

Oil and Gas Industry Segment is Expected to Hold Significant Market Share

- In the oil and gas industry, protecting a pressurized pipeline from corrosion and leaks and minimizing downtime are a few of the crucial responsibilities of the industry. As per a NACE (National Association of Corrosion Engineers) study, the total annual cost of corrosion in the oil and gas production industry is around USD 1.372 billion.

- The presence of oxygen in the gas sample determines a leak in the pressurized pipeline system. The continuous and undetected leak may worsen the situation while impacting on operational flow efficiency of the pipeline. Moreover, the presence of gases, such as hydrogen sulfide (H2S) and carbon dioxide (CO2), in the pipeline system reacting with oxygen can combine and form a corrosive and destructive mixture that can deteriorate the pipeline wall inside out.

- Mitigating such expensive costs is one of the drivers for adopting gas analyzers for preventive actions in the industry. Gas analyzer helps monitor leaks to extend the life of pipeline systems by effectively detecting the presence of such gases. The oil and gas industry is moving toward the TDL technique (tunable diode laser), which enables the reliability of detecting with precision because of its high-resolution TDL technique and avoids common interferences with traditional analyzers.

- As per the International Energy Agency's (IEA) June 2022, net global refining capacity is expected to expand by 1.0 million b/d in 2022 and by an additional 1.6 million b/d in 2023. With refinery gas analyzers commonly used to characterize gases produced during crude oil refining, such trends are expected to increase the market demand further.

- According to IEA, global natural gas supply increased by an estimated 4.1% globally in 2021, partly supported by the market recovery post the COVID-19 pandemic. The detection and monitoring of hydrogen sulfide (H2S) and carbon dioxide (CO2) is pertinent in natural gas processing, creating significant demand for gas analyzers.

- There are many ongoing and upcoming projects in the industry, with massive investments toward expanding production. For instance, the West Path Delivery 2023 project is expected to add about 40 km of new natural gas pipeline to the existing 25,000-km NGTL system, which ships gas across Canada and to the U.S. markets. Such projects are expected to continue during the forecast period, which will fuel the demand for gas analyzers.

Asia Pacific is Expected to Hold Significant Market Share

- Increased investments in new plants in oil and gas, steel, power, chemical, and petrochemicals and the rising adoption of international safety standards and practices are expected to influence market growth. Asia Pacific is the only region to register an oil and gas capacity growth in recent years. About four new refineries were added in the area, which has added nearly 750,000 barrels per day to global crude oil production.

- The development of industries in the region is driving the growth of gas analyzers, owing to their use in the oil and gas industry, such as monitoring processes, increased safety, enhanced efficiency, and quality. Hence, the refineries in the region are deploying gas analyzers in the plants.

- During the forecast period, Asia Pacific is anticipated to be one of the fastest-growing global gas sensors market regions. This is due to a rise in strict governmental regulations and ongoing environmental awareness campaigns. Further, according to IBEF, as per the National Infrastructure Pipeline 2019-25, energy sector projects accounted for the highest share (24%) out of the total expected capital expenditure of INR 111 lakh crore (USD 1.4 trillion).

- Also, the strict government regulations have recently shown significant growth in this region. Moreover, the surge in the government's investments in smart city projects creates a significant potential for smart sensor devices, likely to impel regional Gas Sensors Market growth.

- Rapid industrialization across the different countries in the Asia Pacific region is one of the primary factors driving the growth of the gas detectors market. Smoke, fumes, and toxic gas emissions occur due to highly polluting industries such as thermal power plants, coal mines, sponge iron, steel and ferroalloys, petroleum, and chemicals. Gas detectors are commonly used to detect combustible, flammable, and toxic gases and ensure safe industrial operations.

Gas Sensor, Detector, and Analyzer Industry Overview

The gas analyzer, sensor, and detector market is fragmented due to the presence of many players worldwide. Currently, some prominent companies are developing products with applications centering on the detector. The analyzer segment has applications across clinical assaying, environmental emission control, explosive detection, agricultural storage, shipping, and workplace hazard monitoring. Players in the market are adopting strategies such as partnerships, mergers, expansion, innovation, investment, and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

- December 2022 - Servomex Group Limited (Spectris PLC) extended its offerings to the Asian market by opening a new service center in Korea. As the service center is officially unveiled at Yongin, customers from the semiconductor industry, as well as the industrial process and emissions for oil and gas, power generation, and steel industry, can access invaluable advice and assistance.

- August 2022 - Emerson has announced opening a gas analysis solutions center in Scotland to help plants meet sustainability goals. The center has access to more than ten different sensing technologies that can measure more than 60 other gas components.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Major Power Generation, Transmission, and Distribution Companies in Europe

- 4.5 Hydrogen Value Chain in Europe

- 4.5.1 Major Hydrogen Producing Countries in Europe

- 4.5.2 Stakeholders in the European Hydrogen Industry

- 4.6 An Assessment of the Impact of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Safety Awareness Regarding Occupational Hazards

- 5.1.2 Proliferation of Handheld Devices

- 5.2 Market Restraints

- 5.2.1 High Costs and Lack of Product Differentiation

6 MARKET SEGMENTATION

- 6.1 Gas Analyzers

- 6.1.1 Technology

- 6.1.1.1 Electrochemical

- 6.1.1.2 Paramagnetic

- 6.1.1.3 Zirconia

- 6.1.1.4 Non-disruptive IR

- 6.1.2 End-user Industry

- 6.1.2.1 Oil and Gas

- 6.1.2.2 Chemicals and Petrochemicals

- 6.1.2.3 Water and Wastewater

- 6.1.2.4 Pharmaceuticals

- 6.1.2.5 Other End-user Industries

- 6.1.3 Geography

- 6.1.3.1 North America

- 6.1.3.2 Europe

- 6.1.3.3 Asia-Pacific

- 6.1.3.4 Latin America

- 6.1.3.5 Middle-East and Africa

- 6.1.1 Technology

- 6.2 Gas Sensor

- 6.2.1 Type

- 6.2.1.1 Toxic

- 6.2.1.1.1 Electrochemical

- 6.2.1.1.2 Semiconductor

- 6.2.1.1.3 Photoionization

- 6.2.1.2 Combustible

- 6.2.1.2.1 Catalytic

- 6.2.1.2.2 Infrared

- 6.2.2 End-user Industry

- 6.2.2.1 Oil and Gas

- 6.2.2.2 Chemicals and Petrochemicals

- 6.2.2.3 Water and Wastewater

- 6.2.2.4 Metal and Mining

- 6.2.2.5 Utilities

- 6.2.2.6 Other End-user Industries

- 6.2.3 Geography

- 6.2.3.1 North America

- 6.2.3.2 Europe

- 6.2.3.3 Asia-Pacific

- 6.2.3.4 Latin America

- 6.2.3.5 Middle-East and Africa

- 6.2.1 Type

- 6.3 Gas Detectors

- 6.3.1 Communication Type

- 6.3.1.1 Wired

- 6.3.1.2 Wireless

- 6.3.2 Type of Detector

- 6.3.2.1 Fixed

- 6.3.2.2 Portable

- 6.3.3 End-user Industry

- 6.3.3.1 Oil and Gas

- 6.3.3.2 Chemicals and Petrochemicals

- 6.3.3.3 Water and Wastewater

- 6.3.3.4 Metal and Mining

- 6.3.3.5 Utilities

- 6.3.3.6 Other End-user Industries

- 6.3.4 Geography

- 6.3.4.1 North America

- 6.3.4.2 Europe

- 6.3.4.3 Asia-Pacific

- 6.3.4.4 Latin America

- 6.3.4.5 Middle-East and Africa

- 6.3.1 Communication Type

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles*

- 7.1.1 Emerson Electric Company

- 7.1.2 Teledyne API

- 7.1.3 Siemens AG

- 7.1.4 Servomex Group Limited (Spectris PLC)

- 7.1.5 Honeywell Analytics Inc.

- 7.1.6 Draegerwerk AG & Co KGaA

- 7.1.7 Industrial Scientific Corporation

- 7.1.8 MSA Safety Incorporated

- 7.1.9 Crowncon Detection Instruments Limited

- 7.1.10 Yokogawa Electric Corporation

- 7.1.11 Control Instruments Corporation

- 7.1.12 Membrapor AG

- 7.1.13 Senseir AB

- 7.1.14 Eaton Corporation PLC

- 7.1.15 GfG Gas Detection UK Ltd

- 7.1.16 Figaro Engineering Inc.

- 7.1.17 Robert Bosch GmbH

- 7.1.18 Thermofisher Scientific Inc.

- 7.1.19 Detector Electronics Corporation

- 7.1.20 Alphasense Limited

- 7.1.21 California Analytical Instruments

- 7.1.22 Testo SE & Co. KGaA

- 7.1.23 Trolex Ltd

- 7.1.24 Bacharach Inc.

- 7.1.25 MKS Instruments Inc.

- 7.1.26 RKI Instruments Inc.

- 7.1.27 Horiba Ltd

- 7.1.28 SGX Sensortech Limited (Amphenol Limited)

- 7.1.29 Afriso-Euro-Index GmbH

- 7.1.30 General Electric Company

- 7.1.31 NGK Spark Plugs USA Inc.

- 7.1.32 Delphi Technologies (BorgWarner Inc.)

- 7.1.33 Denso Corporation

- 7.2 Vendor Market Share Analysis