|

市場調查報告書

商品編碼

1402988

故障分析:市場佔有率分析、產業趨勢/統計、成長預測,2024-2029Failure Analysis - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029 |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

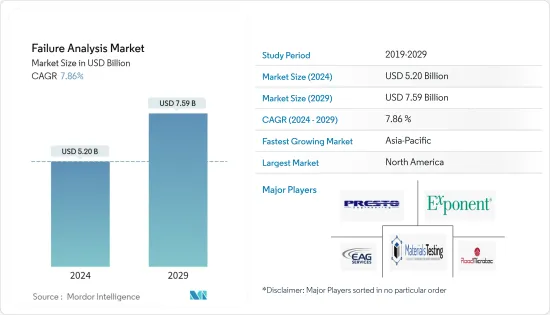

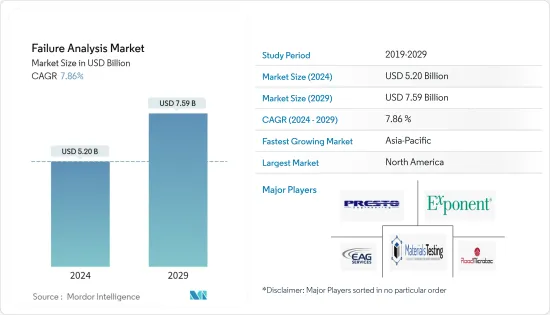

故障分析市場規模預計到 2024 年為 52 億美元,預計到 2029 年將達到 75.9 億美元,在預測期內(2024-2029 年)複合年成長率為 7.86%。

汽車製造商對故障分析的需求不斷增加,以及採用基於視覺和人工智慧 (AI) 的分析工具進行性能分析、動態車輛研究、事故重建等,正在推動市場成長。

主要亮點

- 故障分析是收集和分析資料,以確定故障原因、糾正措施和責任。了解故障的根本原因對於防止未來發生類似事件至關重要。常見原因包括組裝錯誤、誤用/濫用、緊固件有缺陷、維護不善、製造缺陷、材料品質不佳、熱處理不當、意外操作條件、設計錯誤、品質保證差、環境保護不足、鑄造故障等。

- 最終用戶產業的自動化正在刺激市場開拓。為電動車、行動電話、能源系統和其他系統開發電池的公司依靠測試來提高產量,從而創造更有效率、更清潔、更安全的能源來源。公司使用電子顯微鏡技術來了解原子層次的結構。我們也使用光譜工具來發現材料中導致缺陷和低效率的關鍵變化。

- 故障分析技術用於識別現有設備中的問題和缺陷以及現代設備和各行業使用的設備中遇到的問題。由於更嚴格的使用規範、政府安全法規和品管要求,對故障分析設備的需求不斷增加。國家監管部門對技術和工業標準的製定、制定和發布具有管轄權。例如,美國無損檢測協會(ASNT)是其成員,提供NDT相關參考資料、NDT培訓文件和技術會議。

- 顯微鏡的使用型態正在改變。與電子顯微鏡、掃描探針顯微鏡、數位顯微鏡和混合顯微鏡等高階產品相比,傳統顯微鏡因其先進的功能、高解析度和高放大倍率而逐漸失去市場佔有率。然而,這些顯微鏡價格昂貴,這是限制其在醫院、病理實驗室和小型企業中使用的主要因素。

故障分析市場趨勢

汽車產業推動了故障分析的需求

- 隨著對價廉但高品質零件的需求持續成長,汽車產業不斷面臨新的挑戰。必須非常小心,以確保此類組件的設計和製造品質足以承受各種操作環境。

- 在汽車行業,有缺陷的產品可能會導致安全問題和產品召回,從而導致財務損失以及公司的品牌形象。視覺缺陷檢測使製造商能夠高精度地發現和分類汽車零件上的刮痕、凹痕和裂縫等缺陷。這可以避免有缺陷的零件進入生產線,提高品質,並提高安全性和法規遵循。

- 汽車產業正在見證 ADAS 系統、連網汽車、物聯網設備和智慧感測器的快速進步,這些技術可以防止因汽車關鍵零件故障而導致的潛在事故。根據世界衛生組織2022年6月發布的報告,每年約有130萬人死於交通事故。另外還有 2,000 萬至 5,000 萬人遭受非致命傷害,其中許多人因受傷而殘疾。

- 汽車設備故障的可能原因包括產品設計、製造流程、受污染的原料、產品包裝、不當處理和不當校準。這些因素引發了人們對汽車零件製造品質以及為避免此類事故而採取的預防措施的擔憂。

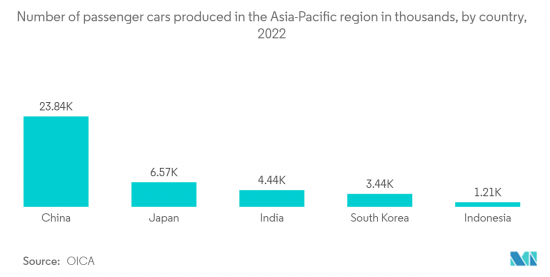

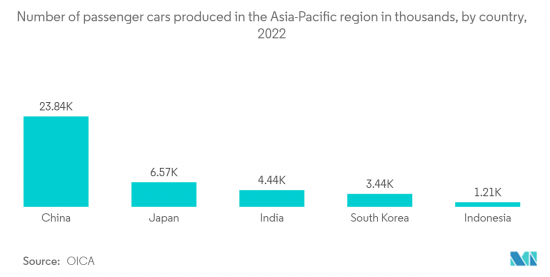

- 近年來,由於小客車和先進車輛的需求增加,亞太地區汽車工業顯著成長。由於該地區人口密度高,小客車的使用量不斷增加。因此,小客車和豪華車的產量不斷增加,推動了該地區的市場成長。根據OICA統計,2022年中國汽車工業生產了約2,380萬輛小客車。

- 汽車零件可能會以各種故障模式發生故障並導致嚴重事故。因此,有必要識別汽車零件更頻繁失效的失效模式。也進行故障分析以確定事故原因。進行此分析是為了了解汽車的哪個部分導致了事故。

北美佔最大市場佔有率

- 以美國為中心的北美地區是最早引入故障分析技術的地區之一,最初引入該技術是為了防止現有商業模式受到重大干擾。該地區是世界上大多數最著名組織的所在地。例如,該國的汽車產業由通用汽車和福特主導,並且嚴重依賴自動化。

- 此外,美國是原油生產的領導者之一,在北美各地擁有多個石油鑽探設施。在各種石油鑽井平台事故造成的破壞性影響之後,對故障分析技術的需求變得更加強烈。最引人注目的事件是2010年的深水地平線漏油事件,當時機械故障導致超過450萬桶石油洩漏到海洋中。

- 近年來,該國經歷了一系列關鍵基礎設施故障。最近的兩個例子,即 2022 年 9 月將加州電網推至極限的熱浪,以及 8 月洪水後密西西比州傑克遜供水系統出現故障,都是維修積壓不斷增加和氣候變遷加劇的跡象。2030 年代進入基礎設施故障的黃金時代。

- 為了從根本上改革美國基礎設施,《兩黨基礎設施法案》(基礎設施投資和就業法案)於2021年11月獲得國會通過,並由拜登總統簽署成為法律。該法重點關注國家基礎設施現代化的關鍵領域,包括改善和重組道路、大眾交通工具、橋樑、港口、鐵路和機場。

- 同樣,為了吸引私營和公共部門投資,加拿大基礎設施銀行負責向加拿大或加拿大部分地區的基礎設施計劃投資 350 億美元,這些項目將從該投資中產生收益。

失效分析產業概述

故障分析市場競爭非常激烈,有幾家主要企業進入該市場。這些領先公司以其強大的市場影響力而聞名,正在積極尋求向各個工業領域的擴張。其中許多公司採用策略聯盟來提高市場佔有率和盈利。此外,在該市場營運的公司也在進行收購以增強其產品能力。該領域的知名公司包括 Exponent Inc.、Rood Microtec GmbH 和 EAG Inc.。

2022 年 12 月,Rood Microtec NV 和 NOVELDA 宣佈建立合作夥伴關係,以鑑定、測試和供應 NOVELDA 的下一代 UWB(超寬頻)設備。這些 UWB 感測器具有驚人的能力,可以檢測最輕微的運動,並監測呼吸和心率。這項突破性技術使 NOVELDA 成為世界上最可靠的佔用感測器供應商。該感測器在各種室內應用中具有巨大潛力,包括家用電器、家庭自動化和智慧建築。 NOVELDA UWB 感測器有望徹底改變使用者體驗、提高安全性並有助於節約能源。

2022年5月,TEC Eurolab與TWI簽署了合作備忘錄(MoU),並於2022年10月開始全面運作。該合作備忘錄將加強對全球 TWI 成員的支持,特別關注歐洲及其他地區的跨國合作機會。該協議為航空、汽車、環境測試、金屬和非金屬材料鑑定、失效分析和非破壞性檢驗等多個領域的聯合測試項目提供了機會。這種夥伴關係有望提高這些領域的能力和服務。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 新進入者的威脅

- 買方議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭公司之間敵對關係的強度

- 產業價值鏈分析

- 宏觀趨勢對市場的影響

第5章市場動態

- 市場促進因素

- 基礎設施老化和維護需求增加

- 技術進步推動市場成長

- 材料、設計和生產方法的創新

- 市場抑制因素

- 設備成本高是市場問題

第 6 章 技術概覽

- 失效模式與影響分析(FMEA)

- 失效模式/影響/死亡分析 (FMECA)

- 功能故障分析

- 斷裂物理分析

- 失效物理分析

- 故障樹分析(FTA)

- 其他

第7章市場區隔

- 依技術

- 二次離子質譜 (SIMS)

- 能量色散 X光光譜 (EDX)

- 化學機械平坦化 (CMP)

- 其他

- 按設備

- 掃描電子顯微鏡(SEM)

- 聚焦離子束 (FIB) 裝置

- 穿透式電子顯微鏡(TEM)

- 雙束系統

- 最終用戶產業

- 車

- 油和氣

- 防禦

- 建造

- 製造業

- 其他

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東/非洲

第8章競爭形勢

- 公司簡介

- Presto Engineering Inc.

- TV SD Limited

- Rood Microtec GmbH

- EAG Inc.

- MASER Engineering BV

- NanoScope Services Ltd

- CoreTest Technologies

- TEC Materials Testing

- McDowell Owens Engineering Inc.

- Leonard C Quick & Associates Inc.

- Crane Engineering

- Exponent Inc.

第9章 投資展望

第10章市場的未來

The Failure Analysis Market size is estimated at USD 5.20 billion in 2024, and is expected to reach USD 7.59 billion by 2029, growing at a CAGR of 7.86% during the forecast period (2024-2029).

The increasing requirement for failure analysis among automobile manufacturers, who also employ vision and artificial intelligence (AI)-based analysis tools for performance analysis, dynamic vehicle studies, accident reconstruction, etc., is augmenting the market's growth.

Key Highlights

- Failure analysis refers to gathering and analyzing data to determine the cause of failure and corrective actions or liability. It is crucial to understand the root cause of failure to prevent similar incidents in the future. Common causes include assembly error, misuse or abuse, fastener failure, inadequate maintenance, manufacturing defects, low-quality material, improper heat treatments, unforeseen operating conditions, design errors, insufficient quality assurance, inadequate environmental protection, and casting discontinuities.

- Automation across the end-user industries has fueled the development in the market studied. Companies developing batteries for electric vehicles, mobile phones, energy systems, and other systems rely on testing to enhance the output, creating a more efficient, cleaner, and safer energy source. Companies use electron microscopy technologies to understand structures that level down at the atomic scale. They also use spectroscopy tools to discover critical changes in materials that cause defects and inefficiency.

- For the identification of problems and deficiencies in existing equipment, as well as those encountered with recent equipment or devices employed across different industries, failure analysis techniques have been applied. The demand for failure analysis equipment is increasing due to stricter use specifications, government safety rules, and high-quality control requirements. Regulatory authorities in various countries have jurisdiction over the development, production, and publication of technical industrial standards. For instance, the American Society for Nondescriptive Testing (ASNT) is a member that provides NDT-related reference materials, NDT training documentation, and technical conferences.

- The usage patterns of the microscopes have changed. Due to its advanced features, high resolution, and magnification power, conventional microscopes are gradually losing their market share in comparison with higher-end products like electron microscopes, scanning probe microscopes, and digital or hybrid microscopes. However, these microscopes are expensive, and this is a major factor limiting the use of them in hospitals, pathology laboratories, or small businesses.

Failure Analysis Market Trends

Automotive Sector is Driving the Demand for Failure Analysis

- The automotive industry has constantly faced new challenges as the demand for inexpensive, high-quality components has repeatedly increased. Extreme diligence must be imparted to ensure that such components are designed and manufactured with sufficient quality to withstand various service environments.

- Safety issues and product recalls, which may cost the company financially as well as its brand image, can be caused by defective products within the automobile industry. Visual defect detection allows manufacturers to find and classify defects in the parts of vehicles, like scratches, dents, or cracks, at a very accurate level. This helps avoid entry into production lines of faulty parts, improve quality, and increase safety and legal compliance.

- The automotive industry has witnessed rapid advancements in ADAS systems, connected vehicles, IoT devices, and smart sensors, which could prevent potential accidents due to malfunctioning of some of the vehicle's vital parts. According to a report published by the WHO in June 2022, every year, the lives of approximately 1.3 million people are cut short as a result of a road traffic crash. Between 20 and 50 million more people suffer non-fatal injuries, with many incurring a disability as a result of their injury.

- Potential causes for automotive device failure may include product design, manufacturing processes, contamination of the source materials, product packaging, improper handling, and improper calibration. These factors have raised concerns over the quality of manufacturing automotive parts and the preventive measures that can be implemented to avoid such incidents.

- Recently, the Asia-Pacific witnessed considerable growth in the automotive industry due to the increasing demand for passenger and advanced vehicles. Passenger vehicles find increased usage due to population density in the region. Therefore, the growing production of passenger and luxury cars is driving the market's growth in the region. According to OICA, China's automotive industry produced approximately 23.8 million passenger cars in 2022.

- The automobile component may fail in different failure modes, causing severe accidents. Therefore, it is essential to identify the failure mode for which the automobile component fails more frequently. Failure analysis is also done to establish the cause of an accident. The analysis is employed to see which component in the automobile caused the accident.

North America Occupies the Largest Market Share

- North America, majorly due to the United States, is one of the earliest adopters of failure analysis techniques, introduced originally to ensure no significant disruptions in the existing business models. The region is home to most of the prominent organizations in the world. For instance, the automotive sector in the country is ruled by General Motors and Ford, which rely heavily on automation.

- Furthermore, the United States is one of the leaders in crude oil production and has several oil rigs spread out across North America. The need for failure analysis techniques is being felt more acutely after the devastating effects of various oil rig accidents, the most notable being the Deepwater Horizon oil spill that occurred in 2010, discharging over 4.5 million barrels of oil into the sea due to a mechanical failure.

- The country has been witnessing critical infrastructure failures for the last few years. Two recent examples, an intense heat wave that pushed California's power grid to its limits in September 2022 and the failure of the water system in Jackson, Mississippi, amid flooding in August, show how a growing maintenance backlog and increasing climate change are turning the 2020s and 2030s into a golden age of infrastructure failure.

- To overhaul the US infrastructure, in November 2021, the Bipartisan Infrastructure Law (Infrastructure Investment and Jobs Act) was passed by Congress and signed into law by President Biden, seeking to invest significant investments in critical infrastructures. It emphasized key sectors to modernize the country's infrastructure landscape, including improving and rebuilding roads, public transit, bridges, ports, rail, and airports.

- Similarly, to attract both private and public sector investment, the Canada Infrastructure Bank is responsible for investing USD 35 billion in revenue-producing infrastructure projects in Canada or parts of Canada by virtue of its investments.

Failure Analysis Industry Overview

The failure analysis market is highly competitive, featuring several key players. These leading companies, known for their significant market presence, are actively seeking to expand their operations across various industry sectors. Many of these firms are employing strategic collaborations to bolster their market share and profitability. Moreover, companies operating within this market are also engaging in acquisitions to enhance their product capabilities. Notable players in this sector include Exponent Inc., Rood Microtec GmbH, and EAG Inc.

In December 2022, Rood Microtec N.V. and NOVELDA proudly announced their partnership for the qualification, testing, and supply of NOVELDA's next-generation UWB (UltraWideband) devices. These UWB sensors have the remarkable capability of detecting even the slightest movements, as well as monitoring breathing and heartbeats. This groundbreaking technology positions NOVELDA as a provider of the most dependable human presence sensors worldwide. These sensors hold tremendous potential for various indoor applications, including consumer electronics, home automation, and smart buildings. The NOVELDA UWB Sensor promises to revolutionize user experiences, enhance safety, and contribute to energy conservation.

In May 2022, TEC Eurolab entered into a Memorandum of Understanding (MoU) with TWI, which became fully operational in October 2022. This MoU is expected to provide enhanced support to TWI members globally, with a particular emphasis on Europe and other cross-border collaboration opportunities. The agreement opens up opportunities for joint testing programs in various areas such as aeronautics, automotive, environmental testing, metal and non-metallic materials qualification, failure analysis, non-destructive testing, and more. This collaboration promises to advance the capabilities and services available in these fields.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions And Market Definition

- 1.2 Scope Of The Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Impacts of Macro Trends on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Ageing Infrastructure and Increasing Need for Maintenance

- 5.1.2 Technological Advancements Drive the Market Growth

- 5.1.3 Innovation in Materials, Design, and Production Methods

- 5.2 Market Restraints

- 5.2.1 High Equipment Cost Challenge the Market

6 TECHNOLOGY SNAPSHOTS ( TECHNIQUE)

- 6.1 Failure Modes Effect Analysis (FMEA)

- 6.1.1 Failure Modes, Effects, and Criticality Analysis (FMECA)

- 6.1.2 Functional Failure Analysis

- 6.1.3 Destructive Physical Analysis

- 6.1.4 Physics of Failure Analysis

- 6.1.5 Fault Tree Analysis(FTA)

- 6.1.6 Other Failure Mode Effect Analysis

7 MARKET SEGMENTATION

- 7.1 By Technology

- 7.1.1 Secondary ION Mass Spectrometry (SIMS)

- 7.1.2 Energy Dispersive X-ray Spectroscopy (EDX)

- 7.1.3 Chemical Mechanical Planarization (CMP)

- 7.1.4 Other Technology Types

- 7.2 By Equipment

- 7.2.1 Scanning Electron Microscope (SEM)

- 7.2.2 Focused Ion Beam (FIB) System

- 7.2.3 Transmission Electron Microscope (TEM)

- 7.2.4 Dual Beam System

- 7.3 By End-user Vertical

- 7.3.1 Automotive

- 7.3.2 Oil and Gas

- 7.3.3 Defense

- 7.3.4 Construction

- 7.3.5 Manufacturing

- 7.3.6 Other End-user Verticals

- 7.4 By Geography

- 7.4.1 North America

- 7.4.2 Europe

- 7.4.3 Asia-Pacific

- 7.4.4 Latin America

- 7.4.5 Middle East and Africa

8 COMPETITIVE LANDSCAPE

- 8.1 Company Profiles

- 8.1.1 Presto Engineering Inc.

- 8.1.2 TV SD Limited

- 8.1.3 Rood Microtec GmbH

- 8.1.4 EAG Inc.

- 8.1.5 MASER Engineering BV

- 8.1.6 NanoScope Services Ltd

- 8.1.7 CoreTest Technologies

- 8.1.8 TEC Materials Testing

- 8.1.9 McDowell Owens Engineering Inc.

- 8.1.10 Leonard C Quick & Associates Inc.

- 8.1.11 Crane Engineering

- 8.1.12 Exponent Inc.