|

市場調查報告書

商品編碼

1435966

單件揀選機器人 - 市場佔有率分析、產業趨勢與統計、成長預測(2024 - 2029)Piece Picking Robots - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

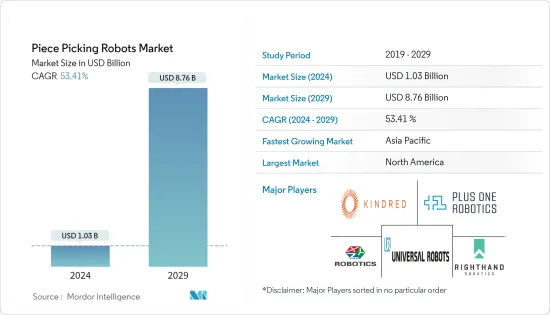

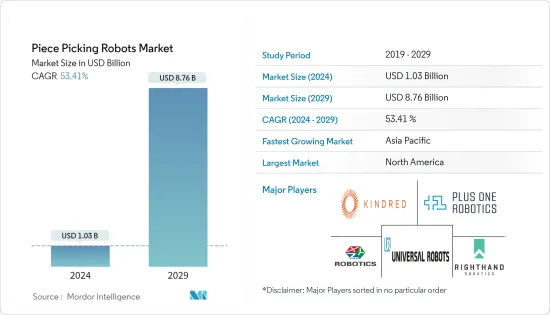

預計2024年單件揀選機器人市場規模為10.3億美元,預計到2029年將達到87.6億美元,在預測期內(2024-2029年)CAGR為53.41%。

COVID-19 顯著增加了自動化解決方案的銷售以及物流需求。儘管供應鏈因封鎖而中斷,但該行業卻取得了顯著成長。倉庫訂單取貨被認為是供應鏈中最耗時的部分,而揀貨機器人可望縮短這一時間。因此,移動工件揀貨機可以取代工人在倉庫內移動所花費的時間。

主要亮點

- 據inVia Robotics Inc.表示,工人在整個倉庫中從一個地點走到另一個地點所花費的時間約佔總揀貨時間的50%,佔所有營運成本的50%以上。此外,在當今緊張的勞動力市場中尋找和留住員工具有挑戰性,通常會導致僱用和培訓臨時工的重複且昂貴的循環。所有這些決定因素累積起來都在推動市場成長。

- 如今,全球安裝了數千台機器人,而五年前,這一領域還不存在。消費者行為推動公司滿足產品和交付個人化的需求。越來越多的公司意識到機器人技術為其業務帶來的眾多優勢。此清單範圍從更快、更準確的揀選到最小化的勞動力需求。勞動力短缺和對在傳統倉庫環境中工作缺乏興趣都發揮了分類機器人的價值。

- 值得注意的是,在製造領域,協作機器人和移動機器人滿足了靈活物料搬運的需求、機器人能夠在大型結構上操作的需求以及快速重新配置工作區域的需求。此外,兩個路線圖提供了對未來移動機器人系統的預測。例如,物料搬運研究所期望自主控制、人工智慧和機器人技術以及運動和手勢敏感技術方面的新能力,這些技術可能會導致物料搬運系統中人類、機器和電腦以全新的方式自由有效地互動。本研究所進一步預測,預計到2025年,紙箱和托盤層面都將實現經濟、高速的卡車裝卸自動化。

- 其次,對於製造業中使用的工件拾取移動機器人,美國機器人技術的最新路線圖預測,到2030年,自動駕駛汽車將能夠在人類可以駕駛的任何環境中行駛,而且比人類駕駛更安全、更可預測。車輛將能夠自行學習如何在以前未見過的場景中駕駛。

- 在勞動力資源不斷萎縮的背景下,製造和物流公司越來越需要滿足消費者對更多選擇和更快交付的需求,這促使企業尋找透過使用分類機器人來實現營運自動化的新方法。隨著公司尋找更有效地部署現有勞動力並最大限度地提高營運生產力和效率的方法,它們在工業應用中得到越來越多的採用。例如,2022年 4月,FedEx、iHerb 和許多其他公司轉向分類機器人系統來解決其履行挑戰。

- 據美國銀行表示,到2025年,45%的製造業將由機器人技術完成。順應這一趨勢,Raymond Limited(印度紡織巨頭)和Foxconn Technology(三星等大型科技製造商的中國供應商)等大公司已分別更換(或計劃更換)10,000 名和 60,000 名工人。將自動化技術融入他們的工廠。因此,增加對自動化的投資將推動市場的發展。

- 此外,工業領域機器人數量的增加將推動所研究的市場成長。據IFR表示,預計2021年全球將出貨約4,35,000台工業機器人。其中亞洲/澳洲的安裝量最多,預計2021年將達到3,06,000台。亞洲/澳洲的工業機器人安裝量預計將達到370,000台到2024年。

單件揀選機器人市場趨勢

協作機器人推動市場

- 協作移動機器人增強了人類的工作能力,提高了準確性,並引導倉庫員工糾正揀選位置並利用 UPC 掃描,進一步減少人為錯誤。根據HMC Investment Securities預測,預計到2025年,全球協作機器人市場規模將達到128億美元左右,單件揀選機器人市場可望獲得提振。

- 雖然協作機器人市場相對較新,但它有望在未來十年內大幅成長。協作機器人是能夠與人類工人一起安全工作並在工廠內外變得更加複雜和有用的機器人。協作機器人的功能不斷進步,同時變得更便宜且更廣泛使用。這兩個決定因素是未來市場爆炸性成長的重要因素。

- 透過協作式單件揀選機器人,有機會將自動化引進當前的揀選環境,而無需中斷或重新安排設置,並見證生產力的顯著提高。例如,2022年5月,現代汽車計畫在2025年在美國投資50億美元,進一步開發自動駕駛、機器人和人工智慧等領域的行動技術

- 推動市場的主要因素是先進機器人的引進,這些機器人能夠在智慧零件組裝和電子元件生產和組裝等領域與人類合作,刺激了對協作機器人的需求。根據 FMI 分析,在協作機器人市場中,2022年上半年觀察到 BPS 值之間的變化 -2022年上半年的展望反映了 99 個單位的成長,與2021年上半年相比,市場預計將飆升-2022年上半年成長81 個基點。

- 此外,2022年8月,Smart Robotics推出了最新的協作機器人系統,名為Smart Fashion Picker。智慧時尚挑選器的名字來自於它的功能 - 協作機器人可以直接從購物車或箱中挑選各種的時尚物品,這些物品被放置在保護性包裝中。智慧時裝挑選器解決了倉庫自動化轉型的痛點。

- 根據HMC Investment Securities預測,全球協作機器人(co-bot)銷售量在美國將達到134,400台左右,而中國預計到2025年銷售量最大,達到2,43,600台,這將進一步推動市場成長。

- 部署協作機器人的應用有很多:包裝、品質測試、物料搬運、機器維護、組裝、焊接等。其中,預計物料搬運領域的協作機器人安裝量將出現最顯著的成長。

- 根據機器人工業協會的說法,促使協作機器人擴大採用的主要因素之一是它們不斷降低的價格標籤。許多協作機器人的價格低於 4.5 萬美元,它們在工廠環境之外也變得可行。無論環境如何,低廉的價格都使自動化投資更容易取得,也更容易證明其合理性。

北美將佔據重要佔有率

- 在倉庫和電子商務履行設施中將協作機器人和移動機器人結合的單件揀選機器人使北美地區受益。美國的機器人大部分是從日本和歐洲進口的(資料來源:IFR)。儘管有許多重要的機器人系統整合商。

- 該地區的 3PL 公司擴大關注不同的客戶資料,以從他們的角度了解最佳應用程式。此外,還觀察到多種趨勢,例如投資、鼓勵駭客馬拉松、趨勢社群和新創實驗室。例如,2022年 10月,印度的 V-Trans 宣布計劃在未來三年內在印度前 40 個城市將其倉庫組合擴大五倍,面積超過 500 萬平方英尺,預計將大幅推動業務源於政府最近公佈的國家物流政策。

- 人們也認為,即使在 COVID-19 引發勞動力短缺問題之前,相關產業也需要進一步自動化。根據 Salary.com 的資料,截至2023年 5月 1 日,美國倉庫工人的平均時薪為 17 美元,但範圍通常在 15 美元至 18 美元之間。

- 具體來說,在農業領域,美國農民每年在勞動力上的支出超過 340 億美元(根據美國農業部的資料),H2B 簽證的稀缺和工人人口的老化導致了向自動化的轉變。儘管採用單件拾取機器人有些牽強,但已考慮了積極的發展。

單件揀選機器人產業概述

單件揀選機器人市場競爭適中,由幾個主要參與者組成。目前,這些參與者中很少有人在市場佔有率方面佔據主導地位。這些廠商提供靈活、經濟高效且高效的移動單件揀選機器人,可實現碼垛和卸垛、儲存和檢索、運輸和包裝等多種倉庫服務的自動化。主要參與者都致力於產品開發,並在現有產品線中引進先進技術,以獲得競爭優勢。市場上的知名企業包括 Plus One Robotics Inc.、Kindred Systems Inc.、Universal Robots A/S、XYZ Robotics Inc. 和 Righthand Robotics Inc. 等。

- 2023年 4月 - OSARO 宣佈建立合作夥伴關係,將其拾取機器人與突破性的 Geek+ 倉庫自動化系統整合。新聯盟為企業提供倉庫履行營運的一站式解決方案以及提高自主移動機器人系統(AMR)和自動儲存和檢索系統(ASRS)投資回報率的策略。

- 2022年 11月 - 亞馬遜推出了其倉庫機器人系列的最新產品,名為 Meet Sparrow,這是一種機械臂,能夠在包裝前挑選單個產品。亞馬遜的 Robin 和 Cardinal 機器人負責挑選和整理要寄送的包裹,而 Sparrow 則可以處理單一產品。此外,亞馬遜還宣布了其機器人團隊開發的另一種機器人:用於移動超大物品的自主移動機器人。該機器人的目標是從亞馬遜商店訂購的 10%的商品,這些商品太長、太寬或太笨重,無法放入公司的吊艙或傳送帶上。

附加優惠:

- Excel 格式的市場估算(ME)表

- 3 個月的分析師支持

目錄

第1章 簡介

- 研究假設和市場定義

- 研究範圍

第2章 研究方法

第3章 執行摘要

第4章 市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭激烈程度

- 產業價值鏈分析

- COVID-19 對自動化產業影響的評估

- 單件揀選機器人軟體技術與發展

第5章 市場動態

- 市場促進因素

- 從整箱或託盤揀選到單件流的轉變以及改進的技術投資

- 增加自動化投資

- 市場挑戰

- 速度較慢、夾具無法處理不尋常的物品以及可靠性問題

第6章 市場細分

- 按機器人類型

- 協作性

- 移動及其他

- 依最終用戶應用程式

- 製藥

- 零售/倉儲/配送中心/物流中心

- 其他最終用戶應用程式

- 按地理

- 北美洲

- 歐洲

- 亞太地區

- 世界其他地區

第7章 競爭格局

- 公司簡介

- Plus One Robotics Inc.

- Kindred Systems Inc.

- Universal Robots A/S

- XYZ Robotics Inc.

- Righthand Robotics Inc.

- Berkshire Grey Inc.

- Robomotive BV

- Lyro Robotics Pty Ltd.

- Knapp AG

- Grey Orange Pte. Ltd.

- Handplus Robotics

- Dematic Group(KION Group AG)

- Nomagic Inc.

- Fizyr BV

- Mujin Inc.

- Nimble Robotics Inc.

- Swisslog Holding AG

- Karakuri Ltd

- Osaro Inc.

- Covariant

- SSI Schaefer Group

第8章 投資分析

第9章 市場的未來

The Piece Picking Robots Market size is estimated at USD 1.03 billion in 2024, and is expected to reach USD 8.76 billion by 2029, growing at a CAGR of 53.41% during the forecast period (2024-2029).

COVID-19 significantly increased the sales of automated solutions, as well as the logistics requirements. Though the supply chain has been disrupted due to the lockdown, the industry has grown significantly. Warehouse order pickups are considered the most time-consuming part of the supply chain, with picking robots promising to shorten it. Mobile piece pickers, thus, can replace the number of hours that workers spend moving around the warehouse.

Key Highlights

- According to inVia Robotics Inc., the time workers spend walking from location to location throughout the warehouse accounts for about 50% of the total pick time and represents more than 50% of all operational costs. Additionally, finding and retaining staff in today's tight labor market is challenging, often resulting in a repetitive and expensive cycle of hiring and training temporary workers. All these determinants, on a cumulative basis, are fuelling market growth.

- There are thousands of robots installed worldwide today that did not exist in this segment just five years ago. Consumer behavior is driving companies to address the demand for the personalization of both products and delivery. More and more companies are realizing the numerous advantages robotics provides their businesses. That list ranges from faster, more accurate picking to minimized labor requirements. Both the labor shortage and a lack of interest in working in traditional warehouse settings play to the value of piece-picking robots.

- Notably, in the manufacturing sector, collaborative as well as mobile robots address the demand for flexible material handling, the need for robots to be able to operate on large structures, and the requirement for rapid reconfiguration of work areas. Moreover, two roadmaps provide predictions for future mobile robot systems. For instance, the material handling institute expects new capabilities in autonomous control, artificial intelligence, and robotics, along with motion- and gesture-sensitive technologies that could lead to material handling systems in which humans, machines, and computers interact freely and effectively in completely new ways. The institute further predicts that it is expected that economical, high-speed automation for loading and unloading trucks should be available, both at the carton and pallet level, by 2025.

- Secondly, for piece-picking mobile robots used in manufacturing, a recent roadmap for US robotics predicts that autonomous vehicles will be capable of driving in any environment in which humans can drive and, furthermore, be safer and more predictable than a human driver by 2030. Vehicles will be able to learn on their own how to drive in previously unseen scenarios.

- The rising need for manufacturing and logistics companies to meet consumer demands for greater choice and faster delivery, against a backdrop of a shrinking labor pool, is leading businesses to look for new ways of automating their operations through the use of piece-picking robots. They are being adopted in increasing numbers in industrial applications as companies look for ways both to deploy their existing workforces more effectively and maximize the productivity and efficiency of their operations. For instance, in April 2022, FedEx, iHerb, and many other companies turned to piece-picking robotic systems to solve their fulfillment challenges.

- According to the Bank of America, by 2025, 45% of all manufacturing will be performed by robotic technology. Following this trend, large firms, such as Raymond Limited (an Indian textile major) and Foxconn Technology (a China-based supplier for large technology manufacturers like Samsung), have replaced (or plan to replace) 10,000 and 60,000 workers, respectively, by incorporating automated technology into their factories. Hence increasing investment in automation drives the market.

- Moreover, the rise in the number of robots in industrial areas will drive the studied market growth. According to IFR, approximately 4,35,000 industrial robots were expected to be shipped worldwide in 2021. Asia/Australia had the most units installed, with an estimated 3,06,000 in 2021. Industrial robot installations in Asia/Australia are expected to reach 370,000 units by 2024.

Piece Picking Robots Market Trends

Collaborative Robots to Drive the Market

- Collaborative mobile robots augment humans' work to improve accuracy and lead warehouse associates to correct pick locations and utilize UPC scanning, further reducing human error. According to HMC Investment Securities, it is expected that, by 2025, the global co-bot market size will reach around USD 12.8 billion, and the Piece Picking Robots Market is envisioned to get a boost.

- While the collaborative robot market is relatively new, it's poised for massive growth over the next ten years. Collaborative robots are robots capable of safely working alongside human workers and becoming more sophisticated and useful inside and outside factory settings. Collaborative robots are advancing in capability while simultaneously becoming cheaper and more widely available. These two determinants are vital contributors to the explosive market growth ahead.

- With collaborative piece-picking robots, there is an opportunity to introduce automation into the current pick environment, not disrupt or rearrange the setup, and witness significant productivity gains. For instance, in May 2022, Hyundai plans USD 5 billion investment in the United States by 2025 to further develop mobility technologies in areas like autonomous driving, robotics, and A.I.

- The primary factor driving the market is the Introduction of advanced robots, capable of working with humans in areas like smart parts assembly and electronics component production and assembly, fueling the demand for collaborative robots. According to FMI analysis, in the Collaborative Robots market, the variation between the BPS values has been observed in H1, 2022 - Outlook over H1, 2022 Projected reflects a gain of 99 units, compared to H1, 2021, the market is expected to spike by 81 BPS in H1 -2022.

- Furthermore, in August 2022, Smart Robotics launched its latest collaborative robotic system named the Smart Fashion Picker. The Smart Fashion Picker's name is derived from its function - the cobot can pick a large variety of fashion items, which are placed in protective wrapping, straight from a cart or bin. The Smart Fashion Picker addresses the pain point of transformation within warehouse automation.

- According to HMC Investment Securities, global collaborative robots (co-bot) sales will reach around 134,400 units in the United States, and china is expected to sell the largest units accounting for 2,43,600 by 2025, which will further drive the market growth.

- There are quite a few applications where collaborative robots are deployed: packing, quality testing, material handling, machine tending, assembly, welding, and others. Among these, the material handling segment is expected to experience the most significant growth in collaborative robot installments.

- According to the Robotic Industries Association, one of the main factors contributing to the increasing adoption of collaborative robots is their constantly lowering price tag. With many collaborative robots available for under USD 45K, they are becoming viable outside the factory setting. No matter the setting, the low price tag makes automation investment more accessible and more comfortable to justify.

North America to Hold Significant Share

- The piece picking robots to combine cobots and mobile robots in warehouses and e-commerce fulfillment facilities has benefitted the North American region. Most of the USA robots are imported from Japan and Europe (source: IFR). Although the presence of numerous important robot system integrators.

- The 3PL companies in the region are increasingly looking at different customer profiles to understand the best applications from their perspectives. Also, multiple trends, such as making investments, encouraging hackathons, trend communities, and startup labs, are being observed. For instance, in October 2022, V-Trans from India announced a five-fold expansion plan in its warehouse portfolio to more than 5 million square feet in the top 40 cities of India over the next three years, as it expects a major boost to business from the government's recently announced National Logistics Policy.

- It is also believed the allied industry needed further automation even before COVID-19 casts the issue of labor tenuousness. According to Salary.com, the average hourly wage for a Warehouse Worker in the United States is USD 17 as of May 01, 2023, but the range typically falls between USD 15 and USD 18.

- Specifically, in the agriculture sector, where farmers have spent over USD 34 billion a year on labor in the United States (according to the USDA), the scarcity of H2B visas and an aging worker population has led to a shift to automation. Though it is farfetched on adopting piece pick robots, active developments have been considered.

Piece Picking Robots Industry Overview

The Piece Picking Robots Market is moderately competitive and consists of several major players. Few of these players currently dominate the market in terms of market share. These players offer flexible, cost-effective, and efficient mobile Piece Picking Robots, which can automate multiple warehouse services such as palletizing & depalletizing, storage & retrieval, transportation, and packaging. Major players are concentrating on product development and introducing advanced technologies in the existing product lines to gain a competitive advantage. Prominent players in the market include Plus One Robotics Inc., Kindred Systems Inc, Universal Robots A/S, XYZ Robotics Inc., and Righthand Robotics Inc., among others.

- April 2023 - OSARO announced a partnership that integrates its pick-and-place robots with groundbreaking Geek+ warehouse automation systems. The new alliance facilitates businesses with a one-stop solution for their warehouse fulfillment operations as well as a strategy to boost the ROI of their autonomous mobile robot systems (AMRs) and automated storage and retrieval systems (ASRS).

- November 2022 - Amazon unveiled the latest addition to its collection of warehouse robots named the Meet Sparrow, which is a robotic arm capable of picking individual products before they get packaged. Unlike Amazon's Robin and Cardinal robots, which pick and organize packages to be sent out for delivery, Sparrow can handle individual products. Further, Amazon announced another robot that is being developed by its robotics team: an autonomous mobile robot for moving oversized items. This robot targets the 10% of items ordered from the Amazon Store that are too long, wide or unwieldy to fit in the company's pods or on its conveyor belts.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porters Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of Impact of COVID-19 on the Automation Industry

- 4.5 Piece-picking Robot Software Technology and Evolution

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 A Shift from Full-case or Pallet Picking to Piece Flow and Improved Technology Investments

- 5.1.2 Increasing Investments in Automation

- 5.2 Market Challenges

- 5.2.1 Slower Speeds, Inability of the Grippers to Deal with Unusual Items, and Reliability Issues

6 MARKET SEGMENTATION

- 6.1 By Type of Robot

- 6.1.1 Collaborative

- 6.1.2 Mobile and others

- 6.2 By End User Application

- 6.2.1 Pharmaceutical

- 6.2.2 Retail/Warehousing/Distribution Centers/Logistics Centers

- 6.2.3 Other End User Applications

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia Pacific

- 6.3.4 Rest of the World

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Plus One Robotics Inc.

- 7.1.2 Kindred Systems Inc.

- 7.1.3 Universal Robots A/S

- 7.1.4 XYZ Robotics Inc.

- 7.1.5 Righthand Robotics Inc.

- 7.1.6 Berkshire Grey Inc.

- 7.1.7 Robomotive BV

- 7.1.8 Lyro Robotics Pty Ltd.

- 7.1.9 Knapp AG

- 7.1.10 Grey Orange Pte. Ltd.

- 7.1.11 Handplus Robotics

- 7.1.12 Dematic Group (KION Group AG)

- 7.1.13 Nomagic Inc.

- 7.1.14 Fizyr B.V.

- 7.1.15 Mujin Inc.

- 7.1.16 Nimble Robotics Inc.

- 7.1.17 Swisslog Holding AG

- 7.1.18 Karakuri Ltd

- 7.1.19 Osaro Inc.

- 7.1.20 Covariant

- 7.1.21 SSI Schaefer Group