|

市場調查報告書

商品編碼

1433834

工業自動化軟體:市場佔有率分析、產業趨勢與統計、成長預測(2024-2029)Industrial Automation Software - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

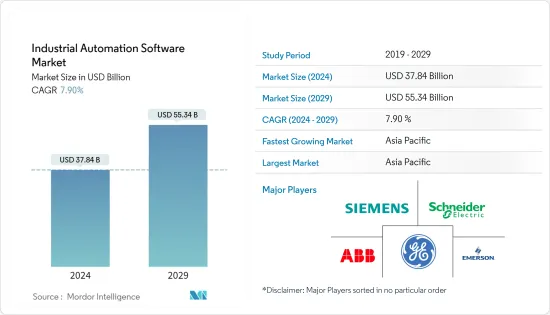

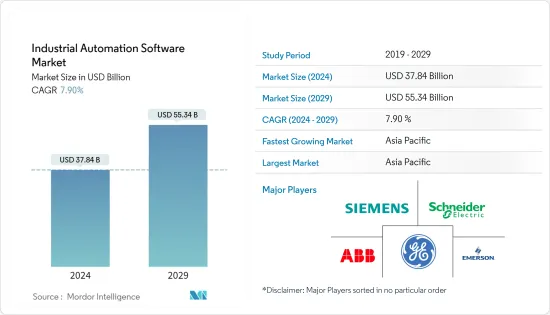

工業自動化軟體市場規模預計到 2024 年為 378.4 億美元,預計到 2029 年將達到 553.4 億美元,在預測期內(2024-2029 年)複合年成長率為 7.90%。

工業自動化軟體是控制整個工業過程的支撐系統。各行業不斷成長的動態需求以及複雜的操作和流程正在推動對工業自動化軟體的需求。工業自動化有助於減少操作所需的機器時間,而這只有透過強大的軟體才能實現。

主要亮點

- 各種類型的工業自動化具有多種優勢,包括更輕鬆的監控、減少廢棄物和提高生產速度。自動化透過標準化來提高質量,並以更低的成本按時為客戶提供可靠的產品。

- 連接工業機械和設備並獲取即時資料在採用SCADA、HMI、PLC系統、MES、APM、APC、PLM、OTS等軟體、提供可視化的控制系統軟體等時發揮重要作用。這些系統有助於減少產品故障、減少停機時間、安排維護、從反應狀態過渡到預測狀態,並為決策建立規格階段。

- 工業IoT(IIoT) 和工業 4.0 是物流鏈開發、生產和管理的新技術方法(稱為智慧工廠自動化)的核心。這些是工業領域的主要趨勢,機器和設備透過網路連接。

- 然而,實施工業自動化解決方案的初始成本很高。此外,僱用和培訓員工來支持解決方案的成本可能會增加總成本並阻礙市場成長。

- 新冠疫情之前製造業出現的趨勢包括全球範圍內擴大採用工業 4.0、隨著政府支持和法規的增加,越來越重視製造過程中的工業自動化。此外,MES與ERP層、SCADA與MES層的整合已經崩壞。儘管COVID-19大流行並沒有引發工業5.0,但它導致了工業4.0的引入,工業4.0利用了多種智慧製造技術。數位化工作流程和自動化不再是一個目標,而是正在成為一項要求。物聯網設備為製造商提供了在這場大流行期間維持收益流的途徑。

工業自動化軟體市場趨勢

SCADA 對市場成長有重大影響

- 監控和資料採集 (SCADA) 軟體在過去十年中經歷了快速成長。 SCADA 系統可協助最終用戶產業的員工分析資料並從遠端位置做出關鍵決策。此外,它還可以在人機介面 (HMI) 上處理、分發和顯示資料,有助於透過快速回應來緩解問題。

- SCADA 系統通常具有緊密配合的硬體和軟體組件。硬體收集資料並將其輸入電腦的處理單元,該單元以不同的時間間隔處理資料。 SCADA 系統記錄事件並將它們記錄在硬碟上的資料夾或將它們傳送到印表機。

- SCADA 系統在許多工業應用中發揮重要作用。在日常業務中使用 SCADA 的行業包括用水和污水系統、發電、輸電和配電系統以及石油和天然氣系統。例如,在石油和天然氣行業,SCADA 用於監控油井和泵站以及水泵壓力和管道流量。

- 2022年2月,通用電氣(GE)Digital宣布推出最新版本的CIMPLICITY 2022 HMI/SCADA軟體。該軟體可為各種規模的應用程式提供更快的回應、降低成本、提高安全性並盈利。 CIMPLICITY 還提供本地、雲端或混合架構的部署選項,從而降低基礎架構和維護成本。

- 人工工資是任何企業最大的支出之一。美國勞工統計局的數據顯示,2021年第三季美國工人的人事費用上漲1.3%,創20年來最大漲幅。 SCADA 等工業自動化解決方案可以減少任務所需的勞動時間,從而降低相關的人事費用。

歐洲市場成長顯著

- 機器人和自動化產業是德國機械工程領域最具創新性的產業之一。這家德國OEM是世界領先的 R&A 公司之一。人機協作 (HRC) 和機器視覺 (MV) 技術被認為是該全球中心的關鍵優勢,該中心容納了來自各個細分市場的機器人公司。包括機器學習和深度學習在內的人工智慧領域的技術發展,很可能會帶動傳統工業機器人和協作機器人的進一步應用。

- SECO 是一家創新嵌入式系統、物聯網 (IoT) 和人工智慧 (AI) 解決方案的全球供應商,最近在德國紐倫堡舉行的 2022 年嵌入式世界博覽會上宣布擴大其人機介面產品系列。除了該公司廣泛的 FLEXY VISION 系列之外,HMI產品系列還擴展到包括 Garz & Fricke 的模組化 Proven Concept (PCT) HMI 系列,具有齊平安裝、後部安裝和麵板安裝安裝選項、顯示智慧和介面。新增了單板電腦,它提供:

- 德國和歐洲的機器視覺產業在過去十年中發展迅速。機器視覺技術的應用不僅在汽車和電子電氣行業(包括半導體),還包括金屬、食品、包裝、非製造業(智慧交通技術、醫療診斷設備、外科技術等)等其他領域。 )正在取得進展。

- 製造技術中心(MTC)和拉夫堡大學產業政策研究中心(IPRC)最近發布的一份報告發現,加速英國工業自動化和機器人技術的採用可以顯著提高該國製造業的生產力。還將成立一個新的國家機器人研究中心,透過消除障礙並加速智慧協作機器人技術的普及來推進智慧製造。

- 許多歐盟研究與創新 (R&I) 計畫始終支持解決方案和技術的開發,使歐洲製造業能夠充分利用數位機會。許多計劃均由未來工廠官民合作關係關係資助,涵蓋數位自動化、製造資產流程最佳化、模擬和分析技術以及製造業中小企業的資訊通訊技術創新等領域。

工業自動化軟體產業概況

工業自動化軟體市場競爭適度,由有影響力的參與者組成。在這個市場上佔有重要佔有率的主要企業正致力於擴大海外基本客群。這些公司正在利用策略合作來增加市場佔有率並提高收益。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 競爭公司之間的敵對關係

- 替代品的威脅

- COVID-19 對產業的影響

第5章市場動態

- 市場促進因素

- 對品質和可靠製造的自動化需求不斷增加

- 對大規模生產的需求不斷增加,同時降低了營運成本

- 工業 4.0 和支援技術的快速採用

- 市場限制因素

- 缺乏專家,安全意識下降

- 實施工廠自動化解決方案的成本高昂

第6章市場區隔

- 依產品

- 監控/資料採集 (SCADA)

- 集散控制系統(DCS)

- 製造執行系統(MES)

- 人機介面 (HMI)

- 可程式邏輯控制器(PLC)

- 按最終用戶產業

- 電力業

- 汽車產業

- 石油和天然氣工業

- 其他

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東/非洲

第7章 競爭形勢

- 公司簡介

- Emerson Electric Company

- ABB Ltd

- Siemens AG

- General Electric Company

- Schneider Electric SE

- Honeywell International Inc.

- Rockwell Automation Inc.

- HCL Technologies Limited

- Parsec Automation Corporation

- SAP SE

- Tata Consultancy Services Limited

- Hitachi Ltd

第8章投資分析

第9章市場的未來

The Industrial Automation Software Market size is estimated at USD 37.84 billion in 2024, and is expected to reach USD 55.34 billion by 2029, growing at a CAGR of 7.90% during the forecast period (2024-2029).

Industrial automation software is the support system in controlling the overall industrial process. The increasing dynamic needs of various industries and complex operations and processes are driving the demand for industrial automation software. Industrial automation helps in reducing the machine hours required for operations, which can be made possible only through robust software.

Key Highlights

- The automation of various industries has offered various benefits, such as effortless monitoring, waste reduction, and increased production speed. Automation offers customers improved quality with standardization and dependable products on time and at a much lower cost.

- Connecting industrial machinery and equipment and obtaining real-time data have played a key role in the adoption of SCADA, HMI, and PLC systems, software such as MES, APM, APC, PLM, and OTS, and control system software that offers visualization. These systems help in reducing the faults in the product, reducing downtime, scheduling maintenance, switching from a reactive state to a predictive state, and creating prescriptive stages for decision-making.

- The Industrial Internet of Things (IIoT) and Industry 4.0 are at the center of new technological approaches for the development, production, and management of the logistics chain, otherwise known as smart factory automation. These are dominating trends in the industrial sector, with machinery and devices being connected via the internet.

- However, the initial costs associated with the implementation of industrial automation solutions are high. Additionally, the costs involved in hiring and training employees who are capable of handling the solution add to the total cost, which can hinder market growth.

- The trends that existed in the pre-COVID manufacturing industry include growing adoption of Industry 4.0 throughout the world, increasing emphasis on industrial automation in manufacturing processes with increasing government support, the growing emphasis on regulatory compliance, increasing complexity and integration of supply chains, surging demand for software systems that reduce time and cost and improve overall equipment effectiveness (OEE) and the collapse of the convergence of MES and ERP layers and SCADA and MES layers. While the COVID-19 pandemic has not triggered Industry 5.0, it has brought about the adoption of Industry 4.0, which utilizes several smart manufacturing technologies. Digital workflows and automation are no longer goals; they are becoming necessary requirements. IoT devices have offered manufacturers a path toward preserving revenue streams during this pandemic.

Industrial Automation Software Market Trends

SCADA has a Significant Impact on the Market Growth

- The supervisory control and data acquisition (SCADA) software experienced rapid growth over the past decade. SCADA system helps the end-user industry employees to analyze the data and make crucial decisions from a remote location. It further assists in mitigating the issues with a quick response as it processes, distributes, and displays the data on the human-machine interface (HMI).

- SCADA systems usually function in close coordination with hardware and software components. The hardware collects and feeds data into the processing unit of a computer, which then processes it at varying time intervals. SCADA systems either record and log events into a folder on a hard disk or send them to a printer.

- SCADA systems play an important role in a number of industrial applications. Some of the industries that use SCADA in their daily operations include water and wastewater systems, electric generation, transmission and distribution systems and oil and gas systems. For instance, in the Oil and Gas industry, SCADA is used to monitor well and pumping sites along with distribution pumping pressure and pipeline flow.

- In February 2022, General Electric (GE) Digital announced the launch of its latest version of CIMPLICITY 2022 HMI/SCADA software. For applications of all sizes, the software can deliver fast response, reduced costs, improved security, and increased profitability. CIMPLICITY also provides options to deploy on-prem, in the cloud, or in a hybrid architecture to reduce infrastructure and maintenance costs.

- The labor wage is one of the largest expenses for any business. As per the US Bureau of Labor Statistics, labor costs for workers in the US rose by 1.3% for the third quarter of 2021, which was the largest hike in 20 years. Industrial automation solutions, such as SCADA, enables the reduction in required labor hours for the tasks, thereby reducing the associated labour costs.

Europe Market to Witness Significant Growth

- The robotics and automation industry is one of the most innovative in the German mechanical engineering sectors. German OEMs rank among the world's leading R&A companies. Human-robot collaboration (HRC) and machine vision (MV) technologies are considered the major strengths in a global hub that hosts robotics players from all market segments. Technological developments in the field of artificial intelligence, including machine learning and deep learning, will lead to further applications of conventional industrial robots and collaborative robots.

- Recently, SECO, a global provider of innovative embedded systems, Internet of Things (IoT), and Artificial Intelligence (AI) solutions, presented its expanded Human Machine Interface product portfolio at embedded world 2022 in Nuremberg, Germany. In addition to the company's wide-ranging FLEXY VISION family, the HMI product portfolio was expanded to include the modular Proven Concept (PCT) HMI series by Garz & Fricke with flush mount, rear mount, and panel mount installation options and an accompanying single board computer providing display intelligence and interfaces.

- The machine vision industry in Germany and Europe has been growing at a fast rate over the past decade. Beyond the automotive industry and the electrical and electronics industries (including semiconductors), other sectors - including the metal, food, and packaging, as well as non-manufacturing industries (e.g., intelligent traffic technology, medical diagnostic equipment, and surgical technologies) - are increasingly making use of machine vision technology.

- As per a recent report produced by the Manufacturing Technology Centre (MTC) and Loughborough University's Industrial Policy Research Centre (IPRC), speeding up the adoption of industrial automation and robotics in the United Kingdom could lead to significant improvements in the country's manufacturing productivity. A new national robotics research center is also being set up in the country to advance smart manufacturing by eliminating barriers and accelerating the widespread use of smart collaborative robotics technologies.

- Much EU-based research & innovation (R&I) programs have constantly supported the development of solutions and technologies that enable the European manufacturing sector to fully utilize digital opportunities. Many of the projects are financed by the Factories of the Future Public-Private Partnership as they cover areas such as digital automation, process optimization of manufacturing assets, simulation and analytics technologies, and ICT innovation for manufacturing SMEs.

Industrial Automation Software Industry Overview

The Industrial Automation Software Market is moderately competitive and consists of some influential players. The key players with a noticeable share in the market are concentrating on expanding their customer base across foreign countries. These businesses are leveraging strategic collaborative actions to improve their market percentage and enhance their profitability.

- February 2022 - Emerson announced the opening of a new integrated manufacturing facility at Mahindra World City, in Chennai, Tamil Nadu. The 145,000-square-foot facility will manufacture major products of the company's Automation Solutions business which provides industrial customers in India and across Asia with technologies to improve productivity, safety, and environmental sustainability.

- July 2021 - Rockwell Automation announced the acquisition of Plex Systems for USD 2.22 billion to expand its industrial cloud software offering. Plex Systems is a pure software-as-a-service, cloud-native smart manufacturing platform operating at scale.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Intensity of Competitive Rivalry

- 4.2.5 Threat of Substitutes

- 4.3 Impact of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increase in Demand for Automation for Qualitative and Reliable Manufacturing

- 5.1.2 Growing Need for Mass Production with Reduced Operation Cost

- 5.1.3 Surge in Adoption of Industry 4.0 and Enabling Technologies

- 5.2 Market Restraints

- 5.2.1 Limited Availability of Professionals and Awareness of Security

- 5.2.2 High Implementation Costs for Factory Automation Solutions

6 MARKET SEGMENTATION

- 6.1 By Product

- 6.1.1 Supervisory Control and Data Acquisition (SCADA)

- 6.1.2 Distributed Control System (DCS)

- 6.1.3 Manufacturing Execution Systems (MES)

- 6.1.4 Human Machine Interface (HMI)

- 6.1.5 Programmable Logic Controller (PLC)

- 6.2 By End-user Industry

- 6.2.1 Power Industry

- 6.2.2 Automotive Industry

- 6.2.3 Oil and Gas Industry

- 6.2.4 Other End-user Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia Pacific

- 6.3.4 Latin America

- 6.3.5 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Emerson Electric Company

- 7.1.2 ABB Ltd

- 7.1.3 Siemens AG

- 7.1.4 General Electric Company

- 7.1.5 Schneider Electric SE

- 7.1.6 Honeywell International Inc.

- 7.1.7 Rockwell Automation Inc.

- 7.1.8 HCL Technologies Limited

- 7.1.9 Parsec Automation Corporation

- 7.1.10 SAP SE

- 7.1.11 Tata Consultancy Services Limited

- 7.1.12 Hitachi Ltd