|

市場調查報告書

商品編碼

1408184

用於物流應用的自主移動機器人:市場佔有率分析、行業趨勢和統計數據、2024年至2029年的成長預測Autonomous Mobile Robots For Intralogistics Applications - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029 |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

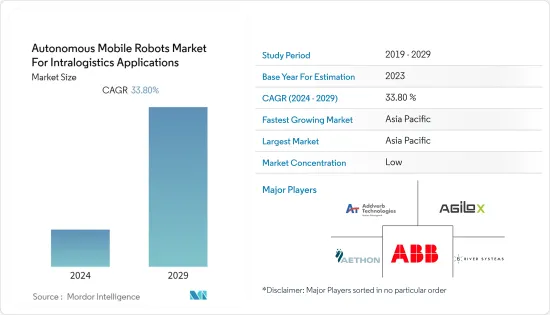

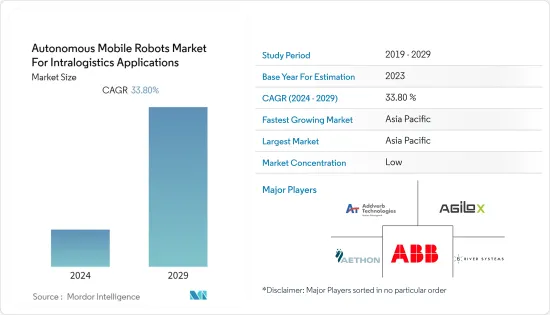

內部物流應用的自主移動機器人市場預計在預測期(2024-2029年)複合年成長率為33.80%

主要亮點

- 隨著技術的進步,自主機器人將在未來的供應鏈中變得更加普遍,並且能夠以更類似於人類的能力進行操作。隨著自主機器人能夠以更一致的品質和生產力水平全天候運作,執行人類無法完成的任務,未來供應鏈的好處將繼續成長。

- 自主移動機器人在全球市場快速成長的一個突出原因是由於其移動性而導致其物理尺寸不受限制,而這是工業機器人普遍反對的。因此,自主移動機器人可以在大型工作空間中運作並探索未知環境,使它們能夠在任何需要的地方執行任務。由於自主移動機器人必須在未知和不確定的環境中運行,因此它們比傳統工業機器人具有更高的智慧。

- 人工智慧、自動化、物聯網、運算能力和機器人等技術的結合將促成新一代智慧工廠的創建。機器人和自動化在過去幾年中發生了很大變化。電子、汽車、食品、金屬加工和物料搬運等不斷成長的行業正在增加對先進自動化的投資,為移動機器人創造了充足的機會。

- 特別是在製造業,由於對靈活物料搬運的需求、大型結構上機器人操作的需求以及工作區域的快速重新配置,自主移動機器人正在獲得發展勢頭。根據物料搬運協會的說法,兩個藍圖提供了對未來移動機器人系統的預測。

- 然而,移動機器人高昂的初始成本是許多考慮部署移動機器人的組織通用關心的問題。儘管初期成本較高,但隨著時間的推移,移動機器人可以提供顯著的投資收益(ROI),特別是在可以提高效率、降低人事費用和提高安全性的環境中。隨著 AMR 的成本不斷下降且其功能不斷增強,考慮實施可能產生的隱性成本非常重要。除了初始設定、部署和重新配置工作之外,還有其他成本,尤其是在機器人不方便使用者使用的情況下。這對市場成長提出了挑戰。

- 由於勞動力短缺、為限制病毒傳播而關閉製造設施以及全國範圍內的封鎖,COVID-19 大流行對自動駕駛市場產生了重大影響。由於對機器人消毒解決方案、工廠和倉庫的機器人物流解決方案或宅配機器人的高需求,COVID-19大流行進一步提振了市場。

自主移動機器人市場趨勢

最大的最終用戶產業是製造業

- 近年來,自動化徹底改變了製造業,並提高了生產力、效率和安全性。自動化技術的最新突破是自主移動機器人(AMR)。這些移動機器人因其能夠確保人類安全並滿足最佳效率的需求而在製造現場贏得了廣泛讚譽。技術的進步使製造商能夠創建適合業務需求的機器人,並將其有效地部署在各種應用中。

- 近年來,製造業受到勞動力市場緊張、對安全性和可靠性的日益重視以及供應鏈中斷的嚴重影響。為了應對這些挑戰,製造商正在藉助機器人等自動化技術來擴大業務,以滿足市場需求。 AMR技術的使用有可能徹底改變和取代傳統的生產方法,透過提高效率為製造業帶來持久的變化。

- AMR 擴大應用於汽車行業,並提供了許多前景。 AMR 可有效最佳化營運、降低成本並提高多個領域的生產力,包括組裝和物料搬運。其多功能性使其能夠有效地執行汽車製造中的焊接、組裝和零件運輸等各種任務。此外,由於所需零件的形狀和尺寸多種多樣,包括焊接車間和車輛組裝廠在內的汽車產業在自動化材料處理方面面臨挑戰。因此,該行業對 AMR 有需求。

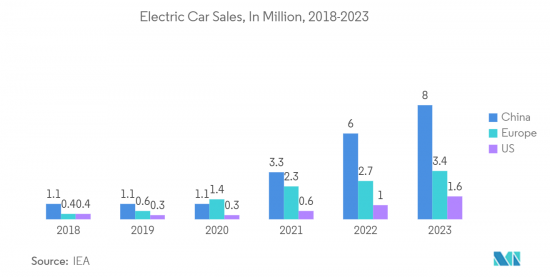

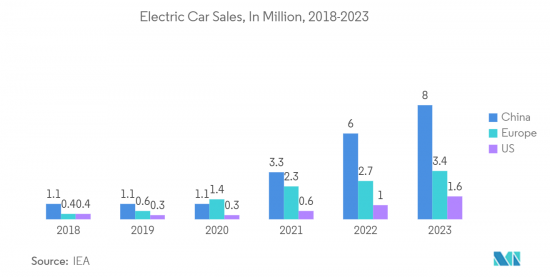

- 電動車(EV)市場正在快速成長,需要快速部署充電基礎設施來支援它。自動充電的整合已成為建立可靠、安全且經濟可行的充電系統的關鍵要素。 AMR充電站是允許機器人在需要時自主充電的設施。對充電站不斷成長的需求預計將為 AMR 技術的進步提供重大機會。

- 2023 年 3 月,中國 NaaS Technology Inc. 宣布推出一款自主移動充電機器人,以滿足日益成長的電動車(EV) 充電需求。這款尖端設備擁有主動車輛追蹤、智慧型充電和自動付款等先進功能,在充電過程中透過機械手臂無縫連接到電動車充電埠。 NaaS Technology Inc. 在納斯達克上市,交易代碼為 NAAS,截至 2022 年 12 月 31 日,已成功連接超過 515,000 個充電器。因此,充電站的投資和安裝將會增加,此類機器人充電設備的採用預計將帶動市場需求。

亞太地區佔主要市場佔有率

- 亞太地區非製造業投資大幅成長。這主要是由於該地區工業的快速成長以及策略性採用自動化技術以提高投資收益。機器人技術的不斷普及、電子商務的擴張以及新型倉儲設施的建立預計將使亞太 AMR 市場成為主導力量。

- 例如,香港憑藉其優越的地理位置、繁榮的營商環境以及新興企業的交通基礎設施,成功吸引了許多跨國公司和新創公司。 High Robotics是該地區的知名公司,透過引進全球首創的自主案件處理機器人(ACR)系統,有效解決了勞動力短缺問題並增強了電子商務產業。這項突破性技術將傳統基於機架的自主移動機器人 (AMR) 的適應性與自動儲存和搜尋系統 (ASRS) 的準確性和生產力無縫整合,徹底改變了倉庫管理。

- 中國擁有全球最大的製造業,產生很大佔有率的市場需求。此外,根據工業和資訊化部 (MIIT) 的數據,儘管因 COVID-19 限制措施導致生產和物流中斷,但與前一年同期比較該國工業產值仍同比成長 3.6%。根據工信部預測,2022年製造業產值預估成長3.1%,佔中國國內生產總值(GDP)的28%。

- 印度的製造業經歷了顯著成長,並已成為一個重要部門。國家製造業政策和 PLI 計畫等政府舉措旨在加強製造業對 GDP 的貢獻並使其與全球標準接軌。因此,在工業 4.0 的普及和製造業擴張的推動下,在可預見的未來,該國的市場成長預計將大幅上升。

- 此外,AMR 也對製造業產生重大影響。其應用不僅限於工廠和倉庫,還延伸到其他產業。然而,在 AMR 投入公共使用之前,還需要進行大規模的安全性試驗。新加坡正在積極進行此類試驗,預計 AMR 的商業用途將迅速增加。該地區如此重大的技術創新預計將在市場上創造巨大的需求。此外,東南亞國家對抗菌素抗藥性日益成長的需求預計將推動市場需求。

自主移動機器人產業概況

由於地區間應用的增加和技術進步,用於物流應用的自主移動機器人市場的特徵是日益分散。這種充滿活力的環境為 Agilox、6 River Systems, LLC、Addverb Technologies Limited、Aethon 和 ABB Ltd 等主要企業提供了利潤豐厚的機會。這些現有競爭之間的競爭非常激烈,主要供應商正在尋求策略性投資以擴大市場佔有率。

2023 年 6 月,ABB 有限公司宣布啟用新的機器人包裝和物流總部,該總部戰略性地位於喬治亞北部喬治亞州阿爾法利塔。這個最先進的設施將成為 ABB 在物流和包裝領域機器人自動化解決方案的獨特中心。

2023 年 4 月,Addverb Technologies Limited 宣布與 Logsquare 建立策略合作夥伴關係,專注於為中東客戶提供創新的自動化解決方案。此次合作旨在提高供應鏈效率、最佳化業務流程並提高收益。此次合作的核心是將 Adverb 的自主移動機器人 (AMR) 產品組合和軟體(包括其車隊管理系統 (FMS))整合到 Logsquare 的綜合客戶解決方案中。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概覽 – AMR 機器人現狀

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家/消費者的議價能力

- 新進入者的威脅

- 競爭公司之間敵對關係的強度

- 替代品的威脅

- 產業價值鏈分析

- 宏觀趨勢的影響

- 專利分析

- 監管狀況

- ROI分析/投資報酬分析

第5章市場動態

- 市場促進因素

- 最終用戶產業對自動化的需求不斷增加

- 與勞工相關的挑戰和技術進步

- 市場挑戰/抑制因素

- 通訊和連接問題(導航和感知)

- 高資本要求

第6章市場區隔

- 按外形尺寸

- 拖車/曳引機/拖船

- 揀貨/履行(單元裝載/甲板裝載/組裝)

- 貨物裝卸(堆高機/平衡重)

- 按使用環境

- 製造業(汽車、電氣/電子、食品和飲料、化學品/藥品)

- 非製造業(物流中心/配送中心/倉庫)

- 按地區

- 美國

- 歐洲

- 亞太地區(不包括中國和印度)

- 中國

- 印度

- 世界其他地區

第7章競爭形勢

- 公司簡介

- ABB Ltd

- Aethon

- Addverb Technologies Limited

- 6 River Systems, LLC

- Agilox

- Guozi Robotics

- Locus Robotics

- Clearpath

- Dematic

- Fetch Robotics

- Greek+

- HikRobot

- Omron

- Seegrid

- Suzhou Junion Intelligent Technology Co., Ltd

- Grey Orange Pte Ltd

- KION GROUP AG

- MOBILE INDUSTRIAL ROBOTS(MIR)(TERADYNE INC.)

- Vecna Robotics, Inc.

第8章 供應商市場佔有率

- 整體 AMR 市場

- 訂單履行 AMR 市場

- 物料搬運 AMR 市場

第9章市場的未來

The Autonomous Mobile Robots Market For Intralogistics Applications Industry is expected to register a CAGR of 33.80% during the forecast period(2024-2029).

Key Highlights

- Autonomous robots will become more common in the future supply chain as technology advances, allowing them to operate with more human-like abilities as autonomous robots develop the ability to work around the clock with higher consistent levels of quality and productivity, performing tasks that humans cannot, the advantages for the supply chain of the future are growing.

- The prominent reason for favoring the rampant growth of autonomous mobile robots in the global market is their unlimited movement by their physical size due to their mobility, which is largely opposed by industrial robots. As a result, autonomous mobile robots are capable of operating in a large workspace and exploring unknown environments and, therefore, are significantly performing tasks wherever needed. Owing to the need to operate in unknown and uncertain environments, autonomous mobile robots are incorporated with much higher-level intelligence than traditional industrial robots.

- The combination of technologies such as artificial intelligence, automation, the Internet of Things, computing power, and robotics enables the building of a new generation of smart factories. Robotics and automation have changed significantly over the past few years. In the continuously growing range of industries such as electronics, automotive, food, metalworking, and material handling, increasing investment in advanced automation creates ample opportunities for mobile robots.

- Notably, in the manufacturing sector, autonomous mobile robots have been gaining significant momentum as they address the demand for flexible material handling, the need for robots to operate on large structures, and the requirement for rapid reconfiguration of work areas. As per the material handling institute, two roadmaps provide predictions for future mobile robot systems.

- However, the high initial cost of mobile robots is a common concern for many organizations considering their adoption. Despite the high initial cost, mobile robots can provide a significant return on investment (ROI) over time, particularly in environments where they can increase efficiency, reduce labor costs, and improve safety. As the costs of AMRs continue to decrease and their abilities improve, it is important to consider the potential hidden expenses that may arise from their implementation. In addition to the initial setup, deployment, and reconfiguration efforts, other costs come under, particularly if the robot is not user-friendly. This poses a challenge to the growth of the market.

- The COVID-19 pandemic had a significant impact on the autonomous mobile market due to the shortage of workforce, the shutdown of manufacturing facilities to restrict the spread of the virus and nationwide lockdowns. The COVID-19 pandemic further boosted the market with the high demand for robotics disinfection solutions, robotic logistics solutions in factories and warehouses, or robots for home delivery.

Autonomous Mobile Robots Market Trends

Manufacturing to be the Largest End-user Industry

- In recent years, automation has revolutionized the manufacturing sector, resulting in enhanced productivity, efficiency, and safety. Among the latest breakthroughs in automation technology are autonomous mobile robots (AMRs). These mobile robots have gained considerable recognition in manufacturing facilities due to their ability to ensure human safety and meet the demand for optimal efficiency. Technological advancements have empowered manufacturers to create robots tailored to their operational requirements and effectively implement them for various applications.

- The manufacturing sector has experienced significant impacts from a highly constrained labor market, increased emphasis on safety and dependability, and supply chain disruptions in recent times. To address these challenges, manufacturers are seeking to satisfy market demands by expanding their operations with the aid of automation technology, such as robotics. The use of AMR technology has the potential to revolutionize and supplant conventional production methods, resulting in lasting changes to the manufacturing industry by revealing greater efficiencies.

- AMRs are increasingly being utilized within the automobile industry, presenting numerous prospects. AMRs effectively optimize operations, diminish expenses, and enhance productivity across various areas, such as assembly lines and material handling. Their versatility enables them to proficiently undertake diverse tasks, including welding, assembly, and part transportation within car manufacturing. Moreover, the automotive industry, encompassing welding shops and vehicle assembly plants, encounters challenges in automating material transport due to the diverse shapes and sizes of required parts. Consequently, the demand for AMRs in this sector has arisen.

- The electric vehicle (EV) market is experiencing rapid growth, necessitating the prompt implementation of a supporting charging infrastructure. The integration of autonomous charging has emerged as a crucial element in establishing a dependable, secure, and economically viable charging system. The AMR charging station is a facility that empowers robots to autonomously recharge as needed. The increasing demand for charging stations is anticipated to present substantial opportunities for the advancement of AMR technology.

- In March 2023, China-based NaaS Technology Inc. unveiled its inaugural autonomous mobile charging robot, catering to the escalating need for electric vehicle (EV) charging. Boasting advanced functionalities such as active vehicle tracking, intelligent charging, and automated payment settlement, this cutting-edge device seamlessly connects with EV charging ports through a mechanical arm during charging sessions. NaaS Technology Inc., traded on NASDAQ under the ticker symbol NAAS, has successfully linked over 515,000 chargers by December 31, 2022. Therefore, the rising investments and establishment of charging stations are expected to adopt such robotic charging facilities, which is expected to drive the demand for the market.

Asia Pacific to Hold Significant Market Share

- The Asia-Pacific region is witnessing a significant surge in investments within the non-manufacturing sector, primarily driven by the region's burgeoning industries and their strategic incorporation of automation technologies to enhance return on investment. The escalating adoption of robotics, the expansion of e-commerce, and the establishment of novel warehousing facilities are anticipated to establish the Asia Pacific AMR market as the dominant force.

- For instance, Hong Kong has successfully enticed numerous multinational corporations and startups due to its advantageous geographical position, thriving business environment, and well-developed transportation infrastructure. Hai Robotics, a prominent company in the region, has effectively tackled the scarcity of labor and bolstered the ecommerce industry by introducing the world's pioneering autonomous case-handling robotic (ACR) system. This groundbreaking technology seamlessly integrates the adaptability of traditional rack-moving autonomous mobile robots (AMR) with the precision and productivity of automated storage and retrieval systems (ASRS), thereby revolutionizing warehouse management.

- China has the largest manufacturing industry in the world and generates a significant share of the market demand. Moreover, the country's industrial output grew by 3.6% in 2022 from the previous year, as per the Ministry of Industry and Information Technology (MIIT), despite production and logistics disruptions from COVID-19 curbs. The output of the manufacturing sector was estimated to have risen by 3.1% in 2022, accounting for 28% of China's gross domestic product (GDP), according to the MIIT.

- Manufacturing in India has become a prominent sector, experiencing substantial growth. The government's initiatives, including the National Manufacturing Policy and the PLI scheme, aim to enhance the manufacturing industry's contribution to GDP and align it with global standards. Consequently, the country's market growth is anticipated to witness a significant upsurge in the foreseeable future, driven by the increasing prevalence of Industry 4.0 and the expanding manufacturing sector.

- Furthermore, AMRs have significantly impacted the manufacturing industry. Their application has extended beyond factories and warehouses to support other industries. However, the implementation of AMRs for public use requires extensive safety trials. Singapore, anticipating a surge in commercial AMR use, is actively engaged in conducting such trials. Such significant innovations in the region are expected to create a significant demand for the market. Moreover, the rising need for AMRs in Southeast Asian countries is expected to drive the demand for the market.

Autonomous Mobile Robots Industry Overview

The autonomous mobile robots market for intralogistics applications is characterized by high fragmentation, with an increasing number of applications and technological advancements across regions. This dynamic environment offers lucrative opportunities to key players such as Agilox, 6 River Systems, LLC, Addverb Technologies Limited, Aethon, and ABB Ltd. The competition among these established competitors is intense, prompting major vendors to seek strategic investments aimed at expanding their market share.

In June 2023, ABB Ltd. announced the inauguration of its new robotic packaging and logistics headquarters, strategically located north of Atlanta in Alpharetta, Georgia. This state-of-the-art facility is poised to serve as ABB's exclusive hub for robotic automation solutions within the logistics and packaging sectors.

In April 2023, Addverb Technologies Limited unveiled a strategic partnership with Logsquare, focusing on delivering innovative automation solutions to customers in the Middle East. The collaboration aims to enhance supply chain efficiency, optimize operational processes, and boost revenue. Central to this partnership is the integration of Addverb's autonomous mobile robot (AMR) portfolio and software, including its fleet management system (FMS), into Logsquare's comprehensive customer solutions.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview - Current Scenario of AMR Robotics

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyer/Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Intensity of Competitive Rivalry

- 4.2.5 Threat of Substitutes

- 4.3 Industry Value Chain Analysis

- 4.4 Impact of Macro Trends

- 4.5 Patent Analysis

- 4.6 Regulatory Landscape

- 4.7 ROI Analysis/Payback Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Demand for Automation across the End-user Industries

- 5.1.2 Labor-related Challenges Coupled with Advancements in Technology

- 5.2 Market Challenges/Restraints

- 5.2.1 Communication and Connectivity Issues (navigation and Perception)

- 5.2.2 High Capital Requirements

6 MARKET SEGMENTATION

- 6.1 By Form Factor

- 6.1.1 Tow/Tractor/Tug

- 6.1.2 Order Picking/Fulfillment (Unit Load/Deck Load/Assembly Line)

- 6.1.3 Load Carrying (Forklifts/Counterbalance)

- 6.2 By Environment of Operation

- 6.2.1 Manufacturing (Automotive, Electrical & Electronics, Food & Beverage, Chemical & Pharmaceuticals)

- 6.2.2 Non-Manufacturing (Logistics Centers/Distribution Centers/Warehouses)

- 6.3 By Geography

- 6.3.1 United States

- 6.3.2 Europe

- 6.3.3 Asia Pacific (Excluding China and India)

- 6.3.4 China

- 6.3.5 India

- 6.3.6 Rest of the World

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Ltd

- 7.1.2 Aethon

- 7.1.3 Addverb Technologies Limited

- 7.1.4 6 River Systems, LLC

- 7.1.5 Agilox

- 7.1.6 Guozi Robotics

- 7.1.7 Locus Robotics

- 7.1.8 Clearpath

- 7.1.9 Dematic

- 7.1.10 Fetch Robotics

- 7.1.11 Greek+

- 7.1.12 HikRobot

- 7.1.13 Omron

- 7.1.14 Seegrid

- 7.1.15 Suzhou Junion Intelligent Technology Co., Ltd

- 7.1.16 Grey Orange Pte Ltd

- 7.1.17 KION GROUP AG

- 7.1.18 MOBILE INDUSTRIAL ROBOTS (MIR)(TERADYNE INC.)

- 7.1.19 Vecna Robotics, Inc.

8 VENDOR MARKET SHARE

- 8.1 Overall AMR Market

- 8.2 Order Fulfilment AMR Market

- 8.3 Material Movement AMR Market