|

市場調查報告書

商品編碼

1405369

林業機械:市場佔有率分析、產業趨勢與統計、2024-2029 年成長預測Forestry Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029 |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

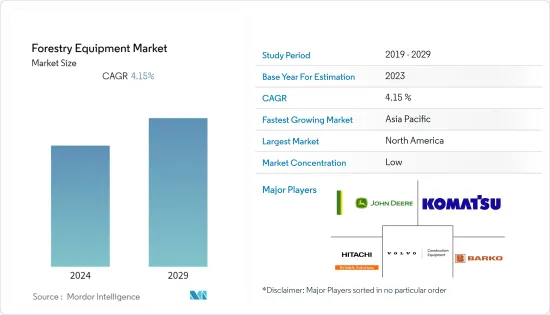

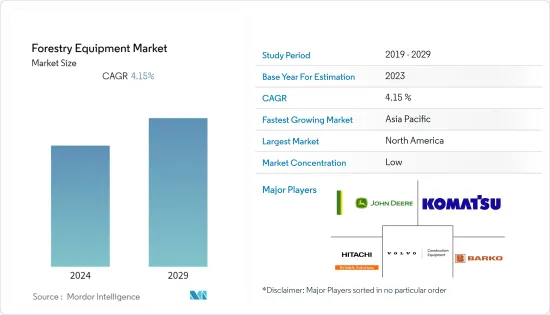

預測期內,林業機械市場預計將從 105.9 億美元成長至 129.8 億美元,複合年成長率為 4.15%。

已開發國家和新興國家的森林保護和管理意識不斷增強,以及從手工林業工作向機械化和自動化的轉變,推動了市場的成長。

主要亮點

- 在目前的林業範圍內,森林管理的角色是規劃和實施森林管理和利用實踐,以實現特定的環境、經濟、社會和文化目標,並且正在迅速擴大。管理目標各不相同,包括保護森林和自然保護區的資源保護,但主要目標往往是木製品的生產。森林管理的基本理念是注重木材生產和“永續採伐”,即在不消耗森林資本的情況下採伐增量木材。

- 健康的森林依賴健康的林產品工業,而林產品工業得到了政府大量投資的支持。例如,2023年4月,美國政府宣布從拜登總統的兩黨基礎設施法案中撥款3,370萬美元,用於加強木製品經濟並促進永續森林管理。這項投資支持復原力強、健康的森林與林業部門強大的農村經濟和就業之間的關鍵聯繫,特別是在依賴國家森林和草原生長和繁榮的社區。

- 此外,在拉丁美洲,林業在恢復歷史悠久的大西洋森林的繁榮方面所發揮的作用越來越受到關注,這些森林曾經覆蓋巴西、巴拉圭和阿根廷的大片地區。但五個世紀的伐木、農業擴張以及聖保羅和里約熱內盧等城市的不斷發展使其支離破碎。因此,30多年來,各種組織一直致力於保護和恢復遺跡。據聯合國稱,約70萬公頃土地已恢復,目標是到2030年保護和恢復100萬公頃,到2050年保護和恢復1500萬公頃。因此,拉丁美洲林業維護活動的增加預計將推動對大型林業機械的需求。

- 然而,高成本和缺乏與林業機械相關的意識預計將減緩市場成長。由於缺乏有關該設備的資訊,它尚未在開發中國家普及。

- COVID-19大流行的影響減弱後,建築和林業機械的需求迅速恢復。預計未來幾年需求將持續穩定成長。在良好的經濟活動和基礎設施計劃的推動下,北美的需求尤其保持強勁。南美市場受到初級產品領域活躍活動的支撐。

林業機械市場趨勢

削片機和研磨機成為最大的現場加工設備領域

- 林業設備市場的現場加工設備部分預計在預測期內將顯著成長。這是由於用作發電廠原料的木質顆粒產量增加。

- 削片機是一種將木材變成木片的機器。與研磨機不同,它們根據設備設定產生尺寸均勻的切屑。在林業工業中,削片機生產用於紙漿木材、顆粒、豬燃料、形勢和任何其他需要均勻木片的應用的材料。削片機有多種配置,其典型特徵包括進料機構、一組旋轉刀、砧座和排放滑槽。

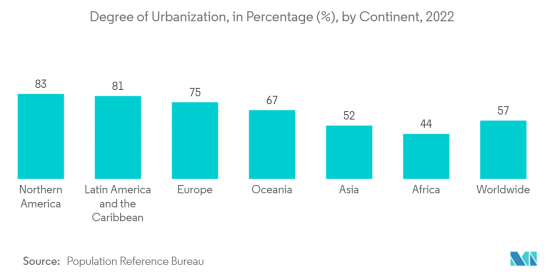

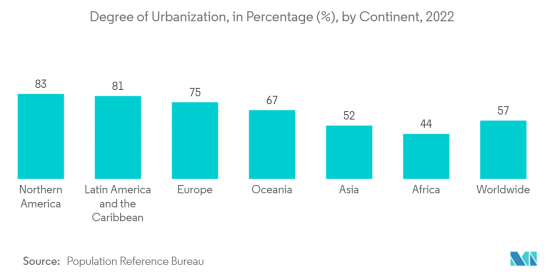

- 林業削片機由提供大規模伐木服務的伐木承包使用。許多企業依靠這些削片機有效地將大樹變成木片。世界快速的都市化摧毀了大片林地,為削片機的使用創造了許多機會。根據人口研究所預測,2022年全球都市化率為57%。北美是都市化程度最高的地區,達 83%。

- 此外,種植園已成為木材能源生產的主要貢獻者,預計未來還會增加。為促進可再生能源發電廠而增加的投資預計將促進木棧板的製造,從而推動對削片機和研磨機的需求。由於森林是木質顆粒的一級資訊來源,森林面積的擴大可能會促使削片機需求激增。

北美佔最大市場佔有率

- 預計北美在預測期內將出現強勁成長,這主要是由於售後市場銷售的增加和向改進的伐木技術的轉變。

- 根據美國農業部統計,美國林產品產業約占美國製造業國內生產總值(GDP)總額的4%,每年生產價值超過2,000億美元的產品。該地區目前木材開採活動激增,木材和非木材林產品的開採量不斷擴大,為林業機械製造商提供了擴大產品供應的機會。

- 在建築設計中擴大使用散裝木材,促使美國的森林管理實踐值得稱讚。因此,對木材產品(包括紙張和生質能能)的需求將會激增,促使對裝載機、覆蓋機和其他現場設備等各種林業機械的需求增加,以促進該地區林業工業的木材採伐。是期待。

- 林業是加拿大最重要的產業,對經濟和就業做出了重大貢獻。林產品總價值每年超過 380 億加元(325 億美元),佔所有製成品的 10%。此外,加拿大是木材開採和生產的領先國家之一,促使了大規模的伐木作業。

- 例如,2022 年末,美國北卡羅來納州伊登頓 52 英畝的原始森林被清除,用於伐木和伐木,以生產用於生質能源的木質顆粒。根據能源資訊管理局 (EIA) 的數據,2021 年美國生產了約 175 億加侖生質燃料,消耗了約 168 億加侖。隨著生質能源能源發電需求的不斷增加,木質顆粒的需求也預計將大幅成長,為林業機械創造應用機會。

林業機械行業概況

林業機械市場高度分散,主要參與者包括迪爾公司、日本小松公司公司、沃爾沃建築設備公司(AB沃爾沃)、日立建機(HCM)和巴科液壓有限責任公司。市場參與者正在採取合作夥伴關係和收購等策略來增強其產品供應並獲得永續的競爭優勢。

- 2023 年 5 月 -日本小松公司推出日本小松公司951XC,這是一款用於在陡坡和鬆軟地面上進行最終切割的收割機。 8輪設計與穩定的日本小松公司概念結合,提供穩定性、高效的機動性和低接地壓力。日本小松公司951XC 也與日本小松公司C164 結合進行了最佳化,小松 C164 是專門為砍伐大樹而設計的收割機頭。此外,靜液壓傳動有利於充分利用引擎動力,在困難地形和高爬坡能力上具有顯著優勢。

- 2023 年 2 月 - 迪爾公司為其履帶/木材裝載機產品線推出了新的中型型號。約翰迪爾的新型 2956G 專為各種規模的伐木承包而設計,他們正在尋找一台能夠提供引擎馬力和液壓功能的最佳組合,同時將機器重量保持在90,000 磅以下的機器。這是理想的解決方案。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

- 產業價值鏈分析

- COVID-19 和宏觀經濟趨勢對產業的影響

第5章市場動態

- 市場促進因素

- 自動化程度的提高推動了林業機械的需求

- 伐木公司更換過時且低效的林業機械

- 市場抑制因素

- 林業機械高成本

- 缺乏林業機械資訊

第6章市場區隔

- 依產品類型

- 伐木設備

- 電鋸

- 收割機

- 伐木歸堆機

- 伐木機

- 貨運代理

- 集材機

- 其他提取設備

- 現場處理設備

- 削片機和研磨機

- 德林弗·鶇

- 其他現場加工機械

- 其他林業機械

- 裝載機

- 覆蓋機

- 其他林業機械

- 選購零件/附件

- 鋸鏈、導桿、圓盤、齒

- 收割機和其他切割頭

- 其他零件/附件

- 伐木設備

- 依地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東/非洲

第7章 競爭形勢

- 公司簡介

- Deere and Company

- Komatsu Ltd.

- Volvo CE(AB Volvo)

- Hitachi Construction Machinery Co. Ltd.(HCM)

- Barko Hydraulics LLC.

- Develon(HD Hyundai Infracore)

- Kesla Oyj

- Ponsse Oyj

- Rottne Industri AB.

- Eco Log Sweden AB

- Mahindra Group

- AGCO Corporation

- Caterpillar Inc.

- Kubota Corporation

- Bell Equipment Limited

第8章投資分析

第9章市場的未來

The forestry equipment market is expected to grow from USD 10.59 billion to USD 12.98 billion over the forecast period, registering a CAGR of 4.15%.

The market is growing owing to the rising awareness about forest preservation and management in several developed and developing countries and the transition in forestry operations from manual work to mechanized and automated modes of operation in forests.

Key Highlights

- With the present scope in the forest industry, the role of forest management has been growing rampantly with the aim of planning and implementing practices for the stewardship and use of forests to meet specific environmental, economic, social, and cultural objectives. While the objectives of management vary widely and include the protection of resources in protected forests and nature reserves, the primary objective has often been the production of wood products. A basic tenet of forest management has been a significant focus on wood production, which is 'sustained yield,' or harvesting the wood increment without drawing down on the forest capital.

- This has been largely supported by significant government investment as healthy forests depend on a healthy forest products industry. For instance, in April 2023, the US government announced USD 33.7 million from President Biden's Bipartisan Infrastructure Law for projecting funds to strengthen the wood products economy and promote sustainable forest management. This investment supports a crucial link between resilient, healthy forests and strong rural economies and jobs in the forestry sector, especially in communities that depend on national forests and grasslands to grow and thrive.

- In addition to this, the role of forestry is gaining prominence in Latin America to bring back the historic flourishing Atlantic Forest that once covered a vast swath of Brazil, Paraguay, and Argentina. But five centuries of logging, agricultural expansion, and the relentless growth of cities like Sao Paulo and Rio de Janeiro reduced it to fragments. Thus, various organizations have been working for more than three decades to preserve and restore what remains. As per the UN, approximately 700,000 ha of land have already been restored, and the goal is to protect and revive 1 million ha by 2030 and 15 million ha by 2050, an area bigger than all of Nepal, Greece, or Nicaragua. Thus, the increase in forestry maintenance activities in Latin America is expected to propel the demand for large forestry machines.

- However, the high cost and lack of awareness associated with forestry equipment is expected to slow down the growth of the market. Due to the lack of information about the equipment, the adoption is still not widespread in developing countries.

- The market saw a rapid recovery in demand for construction and forestry equipment following a decline in the impacts of the COVID-19 pandemic. The demand is expected to show a favorable increase in the upcoming years as well. Notably, demand in North America continued to be robust, driven by good economic activity and infrastructure projects. The South American market was supported by high activity in the commodity segment.

Forestry Equipment Market Trends

Chippers and Grinders to be the Largest On-site Processing Equipment Segment

- The on-site processing equipment segment within the forestry equipment market is projected to experience substantial growth throughout the forecast period. This can be attributed to the escalating production of wood pellets utilized as feedstock for power plants.

- Chippers are machines that can reduce trees into wood chips. They are distinct from grinders in that they generate chips of uniform size, contingent upon the equipment settings. Within the forestry industry, chippers produce material for pulpwood, pellets, hog fuel, landscaping, and any other application that necessitates uniform chips. Chippers are available in a diverse range of configurations, and their typical features comprise a feed mechanism, a set of rotating knives, an anvil, and a discharge chute.

- Lean clearing contractors employ forestry chippers and those providing large-scale tree-clearing services. Many contractors rely on these chippers to effectively reduce large trees into wood chips. Rapid urbanization worldwide destroyed vast forested areas, creating numerous opportunities for using chippers. According to the Population Reference Bureau, worldwide urbanization was 57% in 2022. North America registered the highest degree of urbanization, with 83%.

- Furthermore, it is anticipated that forest plantations may emerge as significant contributors to the production of wood energy, with a projected increase in the future. Escalating investments in promoting renewable power plants are expected to boost the manufacture of wooden pallets, thereby driving the demand for chippers and grinders. Since forests are the primary source of wooden pellets, expanding forest areas is likely to result in a surge in chipper demand.

North America Holds Largest Market Share

- North America is anticipated to experience significant growth during the projected period, primarily due to the rising aftermarket sales and the shift toward modified cut-to-length logging techniques in the region.

- As per the United States Department of Agriculture, the forest products industry in the United States contributes to roughly 4% of the nation's overall manufacturing Gross Domestic Product (GDP), generating an excess of USD 200 billion in products annually. The area is currently experiencing a surge in timber extraction activities, and the escalating extraction of both timber and Non-timber forestry products is anticipated to present opportunities for Forestry equipment manufacturers to augment their product offerings.

- The escalating use of mass timber in architectural design is propelling commendable forest management practices in the United States. The consequent surge in demand for wood products, including paper and biomass for energy, is anticipated to stimulate the need for various forestry equipment, such as loaders, mulchers, and other on-site equipment, to facilitate timber harvesting in the region's forest industry.

- Canada's foremost industry is forestry, with significant economic and employment contributions. Forest products' total worth surpasses CAD 38000 million (USD 32500 million) annually, representing 10% of all manufactured goods. Additionally, Canada ranks among the leading nations in timber extraction and production, resulting in extensive logging operations.

- For instance, in late 2022, a 52-acre indigenous woodland located in Edenton, North Carolina, United States, was subjected to clear-cutting for the purposes of timber harvesting and the chipping of whole trees to produce wood pellets for bioenergy. According to the Energy Information Administration (EIA), approximately 17.5 billion gallons of biofuels were manufactured in the United States in 2021, with approximately 16.8 billion gallons being consumed. As the demand for bioenergy generation continues to increase, the requirement for wood pellets is expected to escalate significantly, thereby creating opportunities for the application of forestry equipment.

Forestry Equipment Industry Overview

The forestry equipment market is highly fragmented, with the presence of major players like Deere and Company, Komatsu Ltd., Volvo CE (AB Volvo), Hitachi Construction Machinery Co. Ltd. (HCM), and Barko Hydraulics LLC. Players in the market are adopting strategies such as partnerships and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

- May 2023 - Komatsu launched the Komatsu 951XC, a harvester for final logging in steep terrain and on soft ground. The eight-wheel design, integrated with the stable Komatsu concept, ensures a machine with stability, efficient maneuverability, and low ground pressure. The Komatsu 951XC is also optimized with the Komatsu C164 - a harvester head specially designed for logging large trees. Further, the hydrostatic transmission facilitates engine power to be utilized entirely, providing considerable advantages in difficult terrain and enhanced climbing ability.

- February 2023 - Deere and Company introduces a new mid-size model to its line-up of crawler log loaders. It is designed for logging contractors of all sizes; John Deere's new 2956G is an ideal solution for customers looking for a machine that provides the best combination of engine horsepower and hydraulics capability while maintaining a machine weight of less than 90,000 lbs.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Degree of Competition

- 4.3 Industry Value Chain Analysis

- 4.4 Impact of COVID-19 and Macro Economic Trends on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Automation to Boost the Forestry Equipment Demand

- 5.1.2 Replacement of Older, Less Productive Forestry Machinery by Logging Firms

- 5.2 Market Restraints

- 5.2.1 High Cost of Forestry Equipment

- 5.2.2 Lack of Information About Forestry Equipment

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Felling Equipment

- 6.1.1.1 Chainsaws

- 6.1.1.2 Harvesters

- 6.1.1.3 Feller Bunchers

- 6.1.2 Extracting Equipment

- 6.1.2.1 Forwarders

- 6.1.2.2 Skidders

- 6.1.2.3 Other Extracting Equipment

- 6.1.3 On-Site Processing Equipment

- 6.1.3.1 Chippers and Grinders

- 6.1.3.2 Delimbers and Slashers

- 6.1.3.3 Other On-Site Processing Equipment

- 6.1.4 Other Forestry Equipment

- 6.1.4.1 Loaders

- 6.1.4.2 Mulchers

- 6.1.4.3 Other Forestry Equipment

- 6.1.5 Separately Sold Parts and Attachments

- 6.1.5.1 Saw Chain, Guide Bars, Discs, and Teeth

- 6.1.5.2 Harvesting and Other Cutting Heads

- 6.1.5.3 Other Parts and Attachments

- 6.1.1 Felling Equipment

- 6.2 By Geography

- 6.2.1 North America

- 6.2.2 Europe

- 6.2.3 Asia Pacific

- 6.2.4 Latin America

- 6.2.5 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Deere and Company

- 7.1.2 Komatsu Ltd.

- 7.1.3 Volvo CE (AB Volvo)

- 7.1.4 Hitachi Construction Machinery Co. Ltd. (HCM)

- 7.1.5 Barko Hydraulics LLC.

- 7.1.6 Develon (HD Hyundai Infracore)

- 7.1.7 Kesla Oyj

- 7.1.8 Ponsse Oyj

- 7.1.9 Rottne Industri AB.

- 7.1.10 Eco Log Sweden AB

- 7.1.11 Mahindra Group

- 7.1.12 AGCO Corporation

- 7.1.13 Caterpillar Inc.

- 7.1.14 Kubota Corporation

- 7.1.15 Bell Equipment Limited