|

市場調查報告書

商品編碼

1404458

球閥:市場佔有率分析、產業趨勢與統計、2024-2029 年成長預測Ball Valve - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029 |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

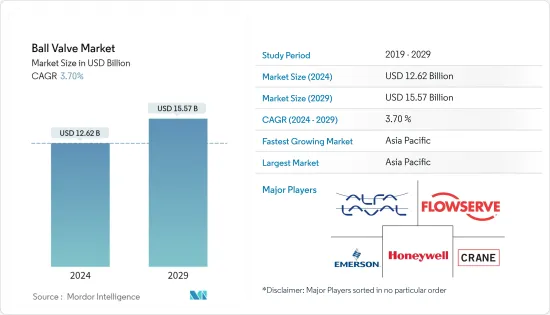

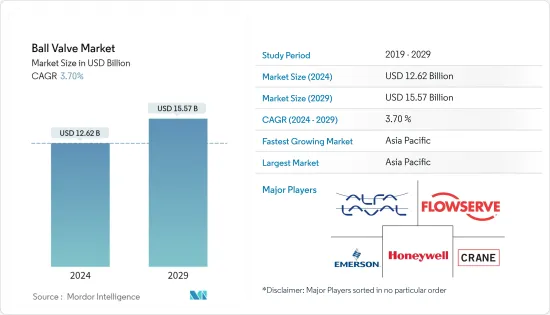

球閥市場規模預計到2024年為126.2億美元,預計到2029年將達到155.7億美元,在市場估計和預測期間(2024-2029年)複合年成長率為3.70%。

石油和天然氣需求的大幅成長被視為促進球閥市場成長的關鍵因素之一。此外,快速的工業化和都市化也是支撐新興市場開拓的重要因素。

主要亮點

- 球閥本質上是直角迴轉驅動閥,其提供強制關閉的能力使其適用於工業應用中的清潔氣體、壓縮空氣和液體服務。然而,當用於泥漿服務時,必須採取措施防止碎片堆積。此外,這些閥門非常堅固,非常適合需要簡單開/關操作的應用。它還非常耐用,無論使用多少次都保持穩定的性能。

- 球閥是石油和天然氣生產設備中應用最廣泛的流體隔離閥。這些閥門也用於為熔爐供應的燃氣系統。這些應用使得產油地區和具有大量精製能力的地區成為產品供應商有吸引力的目標。此外,由於此類工廠將在競標浮動的基礎上開發,因此與此類解決方案提供商合作的市場供應商預計將擁有競爭優勢。

- 在所有類型的材料中,不銹鋼因其高耐腐蝕性而獲得並預計將繼續獲得重要性。由於閥門經常打開和關閉,腐蝕會導致嚴重的問題。這些閥門可以使食品加工廠受益,並且可以在更惡劣的水類型中保持更好的性能。不銹鋼閥門比黃銅等其他材料具有更高的壓力額定功率,這一事實進一步促進了不銹鋼閥門的採用。

- 此外,根據閥口和閥座的數量,提供不同類型的球閥(例如單向、雙向和多向),並補充了它們的工業應用。這些閥門按照高壓管道和低壓管道等分類製造,進一步擴大了使用案例範圍。多家供應商不斷投資創新新產品,這是推動市場的主要因素之一。

- 閥門技術的進步,包括智慧閥門的出現以及自動化和控制系統的結合,正在為市場帶來新的前景。日益成長的環境問題和監管要求推動了對環保和節能閥門的需求。提供具有最小排放、低洩漏率和能源效率的節能球閥的製造商可以滿足對永續解決方案不斷成長的需求。

- 球閥通常採用較大直徑,因為蝶閥等替代閥門類型往往具有較小且較弱的閥桿。在空間限制和結構負荷至關重要的情況下,例如海上鑽探平臺和浮式生產儲油卸油設備(FPSO),使用者會選擇球閥的替代品。此外,流量控制的精度有限對所研究市場的成長構成了挑戰。

- COVID-19 的影響因供應商而異,一些供應商為食品業提供球閥並提供服務,而其他供應商僅為石油和天然氣行業提供服務。參與食品加工的供應商受疫情影響較小,因為食品相關產品的生產被視為基本服務,而且這些設施正在加班以滿足需求。然而,隨著大流行引發的限制幾乎取消並且各行業已恢復全面營運能力,預計所研究的市場將在預測期內出現向上成長。

球閥市場趨勢

食品加工業可能有重要的應用

- 食品加工產業是球閥重要應用的一個值得注意的領域。產品填充過程需要保持穩定的流量,因此球閥成為重要組件。該行業使用兩種類型的閥門:直接接觸材料的閥門和用於水和蒸汽等公共產業服務的閥門。在這兩種情況下,閥門都必須符合多項行業法規,特別是那些與食品材料接觸的行業法規。這對製造商獲得監管部門批准提出了重大挑戰,並且必須設計符合嚴格行業標準的閥門。

- 球閥在控制和維持大體積、溫度和壓力方面非常有效。在食品和飲料領域,衛生級球閥用於連接和調節輸送管道,由於其材質為不銹鋼,保證了所輸送流體的純淨、穩定性和品質。衛生級閥門也易於消毒和清洗,促進衛生。隨著各種供應商不斷推出產品,市場預計將會成長。

- 例如,2022 年 11 月,致動閥和設備控制製造商 Valworx 最近推出了一系列適合部署在食品和飲料製造領域的新衛生球閥。這些球閥具有突出的位置指示器,並且與 Namur 和 ISO 安裝相容。閥門有二通閥和三通閥,尺寸從 0.5 英吋到 4 英吋不等。新系列閥門符合 FDA、USD A 和 3-A 標準。

- 不銹鋼因其廣泛的耐腐蝕性而日益被認為是一種重要材料,這是食品加工領域的關鍵問題。當暴露於更具腐蝕性的水成分時,這些閥門也表現出卓越的耐用性,為食品加工廠提供了顯著的優勢。此外,與黃銅等替代材料相比,不銹鋼閥門具有更高的壓力額定功率。例如,典型的 1 英吋黃銅球閥的額定功率等級為 600 PSI,而相同尺寸的標準不銹鋼球閥的壓力額定功率為 1000 PSI。這項特性使其特別適合食品加工產業的高壓應用。

- 世界各地都市化不斷提高,對包裝食品的需求顯著增加。生活方式的改變,特別是在都市區,也導致包裝和加工食品的需求增加。為了確保糧食安全並實現自給自足的目標,各國正在透過監管改革和建立經濟特區等努力來發展食品加工業。例如,2022年6月,新興國家宣布提供3.75億美元資金支持美國肉類和家禽加工廠計劃。這些因素可能會產生對食品業廣泛使用的球閥的需求。

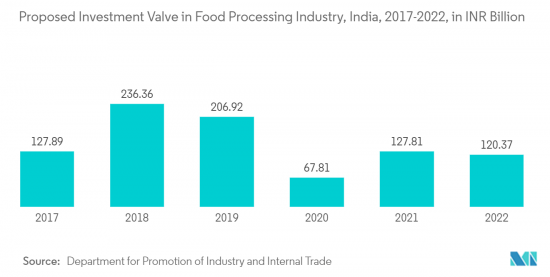

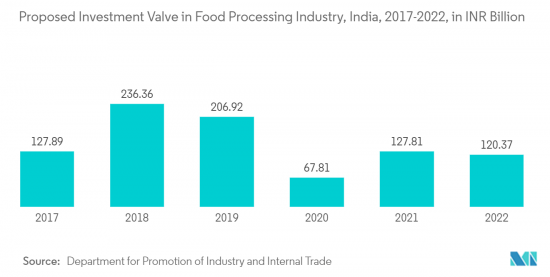

- 其他國家也觀察到了這種有利於市場成長的情況。根據工業和國內貿易促進部的報告,到 2022 年,印度食品加工產業的擬議投資價值為 1,203.7 億印度盧比(14.7 億美元)。印度食品加工工業部正在努力鼓勵整個價值鏈的投資,包括實施 PLI 計劃,到 2026-27 年將食品加工能力擴大近 3,000 億印度盧比(36 億美元)。創造額外的直接和間接就業機會。這些舉措預計將為球閥提供重要機會。

預計北美將佔據主要市場佔有率

- 北美是球閥的主要市場,石油和天然氣、電力、食品和包裝以及化學品等多個行業對球閥的需求量很大。美國和加拿大顯示出巨大的需求,工業自動化的快速整合進一步推動了這一需求。這一趨勢預計將刺激該地區球閥市場的需求。

- 在北美地區,對智慧型球閥的需求不斷增加。該地區的主要行業正在轉向球閥,球閥結合了處理器和網路功能,以補充透過中央控制站協調的先進監控技術。製程工業中擴大採用自動化進一步強化了這種需求趨勢。

- 與加拿大相比,美國在區域需求成長中發揮關鍵作用。在美國,幾乎每個最終用戶領域的需求都在成長,主要是石油和天然氣、精製和發電。能源消費量的增加是這些產業需求成長的主要驅動力。例如,根據EIA的數據,2022年美國即時能源消耗總量約為102.92兆BTU,其中石油消費量約為31%。

- 此外,對石油和天然氣以及其他石油產品的需求不斷增加也鼓勵石油生產商增加產量並開拓新油田,預計這將推動所研究市場的進一步成長。例如,2022年11月,加拿大能源承包協會(CAOEC)宣布,預計2023年加拿大將鑽探約6,409口井,比2022年增加約15%。

- 隨著該地區人口的成長以及各行業消費量預計將增加,預計該地區可能會安裝新的水處理設施,以滿足對球閥的需求。一個著名的例子是紐約州官員在 2022 年 9 月宣布,他們已撥款超過 2.32 億美元用於七個城市的用水和污水基礎設施計劃。紐約州環境設施公司提供資金和低成本融資方案,以促進水基礎設施計劃,累積支出超過 7.63 億美元。這些建立處理廠的投資必然會增加對球閥的需求。

- 球閥用於調節壓力和流量。其防漏性能是一個顯著的特性,在處理液體的化學工業中特別有利。 2022年7月,BASF宣布了計劃的最終投資決定,旨在將其位於路易斯安那州阿森松教區的化學製造綜合體的產能提高一倍。該擴建計劃歷時七年多,總資本投資超過 10 億美元,使該公司能夠滿足北美地區建築、電器、道路運輸和汽車等多個行業對其產品不斷成長的需求。 。 變得。

球閥產業概況

球閥市場分散,由多個參與企業組成,但目前沒有一個集團佔據較大佔有率。每家公司都進行併購以提高其產品的專業化。由於其廣泛的消費者基礎,該市場被視為利潤豐厚的投資機會。主要市場參與企業包括福斯公司、阿法拉伐、克瑞公司和霍尼韋爾國際公司。

2022 年 11 月,克林格流體控制推出了更堅固的球閥「Monoball KHO」。該公司表示,該閥門具有鑄造精良的外殼,比其前身能夠吸收更多的力。此外,這些閥門有多種型號可供選擇,螺紋和法蘭也可根據客戶要求量身定做。

2022 年 11 月,丹佛斯宣布推出適用於無油系統的新排放解決方案。據該公司稱,這些新型止回閥和截止閥結合了阻尼噴嘴止回閥、截止閥和擴散器功能,以滿足應用需求。此外,系統的分離式停止和止回功能可實現快速存取並提高密封可靠性,並且鎖定環設計可防止球閥意外關閉。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間的敵對關係

- 產業價值鏈分析

- COVID-19 對市場的影響

第5章市場動態

- 市場促進因素

- 各國工業化進展

- 對製程安全的需求不斷成長

- 市場挑戰

- 因閥門維修而停機

第6章市場區隔

- 按材料(定性分析)

- 鑄鐵

- 鋼

- 合金底座

- 其他材料

- 按最終用戶產業

- 油和氣

- 化學

- 水/污水

- 電力

- 食品和飲料

- 製藥

- 其他最終用戶產業

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東/非洲

第7章競爭形勢

- 公司簡介

- ALFA LAVAL

- CIRCOR International Inc.

- Crane Co.

- Castel SRL

- Sanhua USA

- Curtiss-Wright Corporation

- Danfoss A/S

- Emerson Electric Co

- Georg Fischer Ltd

- Flowserve Corporation

- Hitachi Ltd

- Honeywell International Inc.

- KITZ Corporation

- Mueller Water Products Inc

第8章投資分析

第9章 市場未來展望

The Ball Valve Market size is estimated at USD 12.62 billion in 2024, and is expected to reach USD 15.57 billion by 2029, growing at a CAGR of 3.70% during the forecast period (2024-2029).

A significant rise in the demand for oil and gas is expected to be one of the significant factors contributing to the ball valve market growth. Additionally, rapid industrialization and urbanization are other essential factors supporting the development of the studied market.

Key Highlights

- The ball valve is essentially a valve that requires a quarter-turn to operate and is well-suited for clean gas-compressed air and liquid service in industrial applications, owing to its ability to provide a secure shutoff. However, when used for slurry service, measures must be taken to prevent the accumulation of debris. Furthermore, these valves are incredibly robust and highly suitable for applications requiring a simple on/off action. They're also highly durable and maintain consistent performance even after many use cycles.

- Ball valves are the most widely adopted fluid shutoff valves among oil and gas production facilities. These valves are also used in fuel gas systems feeding furnaces. Such applications make the oil-producing regions and regions with huge oil refining capacities attractive targets for the product vendors. Furthermore, as such plants are developed on tender floatation, the market vendors with partnerships and collaborations with such solution providers are expected to have a competitive advantage.

- Among all the types of materials, stainless steel is gaining and is expected to witness importance since they are more corrosion-resistant. Because valves open and close frequently, corrosion can cause significant issues. These valves hold up much better to harsher water types, which can benefit food processing plants. The fact that stainless steel valves also have a higher pressure rating than other materials, such as brass, further drives their adoption.

- Furthermore, the availability of ball valves in different variants, such as unidirectional, bidirectional, or multi-directional, depending on valve ports and the valve seat number, also complements their industrial adoption. These valves are also manufactured based on the classification for high-pressure or low-pressure pipelines, further expanding their use cases. Several vendors are constantly investing in innovative new products, which is acting as one of the major factors driving the market.

- The advancements in valve technology, including the emergence of smart valves and the incorporation of automation and control systems, present fresh prospects in the market. The rising environmental concerns and regulatory mandates fuel the need for eco-friendly and energy-efficient valves. Manufacturers who provide ball valves with minimized emissions, low leakage rates, and enhanced energy efficiency can seize the expanding demand for sustainable solutions.

- Ball valves are commonly employed in larger bore sizes, as alternative valve types like butterfly valves tend to have smaller and weaker stems. In situations where space constraints and structural load are paramount, such as offshore drilling platforms and floating production storage and offloading (FPSOs), users opt for alternatives to ball valves. Furthermore, the limited precision in flow rate control poses a challenge to the growth of the examined market.

- The impact of COVID-19 was different on the vendors since some offer and service ball valves for the food industry, while others offer only for the oil and gas sector. The pandemic less impacted vendors catering to food processing since the manufacturing of food-related items was deemed an essential service, and those facilities worked extra hours to fulfill the demand. However, with the pandemic-led restriction almost removed from everywhere and industries returning to their full-scale operational capabilities, the studied market is expected to experience upward growth during the forecast period.

Ball Valve Market Trends

Food Processing Industry Expected to Have Significant Applications

- The food processing industry is a notable sector where ball valves find significant application. The process of product fillings necessitates the maintenance of a regulated flow, making ball valves an essential component. The valves employed in the industry are of two types: those that come in direct contact with the material and those used in utility services such as water and steam. In both cases, the valves must comply with several industry regulations, particularly those that come in contact with food material. This presents a considerable challenge for manufacturers to obtain regulatory approvals, requiring them to design valves that meet stringent industry standards.

- Ball valves are highly efficient in controlling and maintaining high volume, temperature, and pressure. In the food and beverage sector, sanitary ball valves are utilized to connect and regulate conveyance pipes, ensuring the purity, stability, and quality of fluids during transport due to their stainless steel construction. Sanitary valves are also easy to disinfect and clean, promoting hygiene. The market is expected to grow due to continuous product launches by various vendors.

- For instance, in November 2022, Valworx, a producer of actuated valves and equipment controls, recently introduced a novel range of hygienic ball valves suitable for deployment in the food and beverage manufacturing sector. These ball valves are equipped with a conspicuous position indicator and are compatible with Namur and ISO mountings. The valves are obtainable in two- and three-way configurations and available in various sizes ranging from 0.5 to 4 inches. The new line of valves conforms to the FDA, USDA, and 3-A standards.

- Stainless steel is increasingly recognized as a crucial material due to its extensive resistance to corrosion, a significant concern in the food processing sector. These valves have also demonstrated exceptional durability when exposed to more aggressive water compositions, offering notable advantages to food processing plants. Moreover, stainless steel valves possess a higher pressure rating compared to alternative materials like brass. For instance, a typical 1-inch brass ball valve may have a pressure rating of 600 PSI, whereas a standard stainless steel ball valve of the same size would likely have a pressure rating of 1000 PSI. This characteristic renders them particularly suitable for high-pressure applications within the food processing industry.

- The growing urbanization rate across various parts of the world significantly enhances the demand for packaged food. Changing lifestyles, especially in urban areas, also contribute to the ever-increasing demand for packaged and processed foods. To ensure food security and achieve self-sufficiency goals, various countries are making efforts such as making regulatory changes and developing special economic zones to develop food processing industries; for instance, in June 2022, USDA announced a fund of USD 375 million in support for meat and poultry processing plant projects in the United States. Such factors will create the demand for the ball valves for their extensive usage in the food industry.

- A favorable scenario for the growth of the studied market has also been observed in other countries. The Department for Promotion of Industry and Internal Trade reported that the proposed investment in the food processing sector in India was valued at INR 120.37 billion (USD 1.47 billion) in 2022. Efforts are being taken to encourage investments across the entire value chain by the Indian Ministry of Food Processing Industries, including the implementation of the PLI scheme, which is expected to expand food processing capacity by nearly INR 30,000 crore (USD 3.6 billion) and create additional direct and indirect employment by the year 2026-27. Such initiatives are expected to offer significant opportunities for the ball valves.

North America is Expected to hold a Significant Market Share

- North America stands as a prominent market for ball valves, boasting substantial demand across diverse industries such as oil and gas, electricity, food and packaging, and chemicals. Both the United States and Canada exhibit immense demand, further fueled by the swift integration of industrial automation. The projected trend is expected to stimulate the market demand for ball valves in the region.

- North American area is witnessing a growing requirement for intelligent ball valves. Prominent regional industries are transitioning towards ball valves that incorporate processors and networking capabilities to complement advanced monitoring technology, which is coordinated through a central control station. The increased adoption of automation in process industries further reinforces this demand trend.

- The United States assumes a pivotal role in augmenting regional demand in contrast to Canada. The nation experiences a growing demand across nearly all end-user sectors, particularly in oil and gas, refining, and power generation. Higher energy consumption is the primary factor behind the higher demand across these sectors. For instance, according to EIA, total immediate energy consumption in the United States in 2022 was about 102.92 quadrillions Btu, of which petroleum consumption was about 31 percent.

- Furthermore, higher demand for oil & gas and other petroleum products also drives oil producers to increase their production and explore new oil extraction sites, which are expected to help the studied market grow further. For instance, in November 2022, the Canadian Association of Energy Contractors (CAOEC) announced that in 2023, it expects about 6,409 wells to be drilled in Canada, an approximately 15 percent increase from 2022.

- It is expected that new water treatment facilities will likely be set up in the region to feed the demand for ball valves as a result of an anticipated increase in regional population and increased water consumption across different sectors. A notable example is the recent announcement by New York State officials in September 2022, wherein they allocated over USD 232 million for water and sewer infrastructure projects in seven municipalities. The New York State Environmental Facilities Corporation granted funds and offered low-cost financing packages to facilitate water infrastructure initiatives with a cumulative expenditure exceeding USD 763 million. These investments in establishing treatment plants will inevitably augment the need for ball valves.

- Ball valves are utilized to regulate pressure and flow. Their leak-proof nature is a notable attribute that renders them highly advantageous, particularly in the chemical industry involving liquids. In July of 2022, BASF declared its final investment decision on a project worth USD 780 million, aimed at doubling the production capacity of its chemical manufacturing complex in Ascension Parish, Louisiana. The expansion project, which spans over seven years and represents a combined capital investment of over USD 1 billion, will enable the company In order to meet the growing demand for its products in a variety of sectors, such as construction, appliances, road haulage, and automobiles throughout North America.

Ball Valve Industry Overview

The ball valve market is fragmented and consists of several players, with no group currently holding a major share in the market. The companies are engaging in mergers and acquisitions to increase their expertise in the product. The market is viewed as a lucrative investment opportunity due to its wide consumer base. Some key market players include Flowserve Corporation, Alfa Laval, Crane Co., Honeywell International Inc., etc.

In November 2022, Klinger Fluid Control launched a more robust ball valve, Monoball KHO. According to the company, this valve has a neatly cast housing that can absorb even more force than the previous model. Furthermore, these valves are available in various models and with threads or flanges that can be adapted to customer requirements.

In November 2022, Danfoss launched its new discharge solution for oil-free systems. According to the company, these new check and stop valves incorporate a damped nozzle check valve, stop valves, and diffuser function to address the application requirements. Furthermore, the decoupled stop and check functions of the system allow fast access and improve the reliability of sealing, while the lock ring design prevents unintentional ball valve closes.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Industrialization in Various Countries

- 5.1.2 Growing Demand for ProcessSafety

- 5.2 Market Challenges

- 5.2.1 Downtime Due to Repairing of Valves

6 MARKET SEGMENTATION

- 6.1 By Material (Qualitative Analysis)

- 6.1.1 Cast Iron

- 6.1.2 Steel

- 6.1.3 Alloy Based

- 6.1.4 Other Materials

- 6.2 By End-User Industry

- 6.2.1 Oil and Gas

- 6.2.2 Chemicals

- 6.2.3 Water and Waste Water

- 6.2.4 Power

- 6.2.5 Food and Beverage

- 6.2.6 Pharmaceutical

- 6.2.7 Other End-User Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia-Pacific

- 6.3.4 Latin America

- 6.3.5 Middle East & Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ALFA LAVAL

- 7.1.2 CIRCOR International Inc.

- 7.1.3 Crane Co.

- 7.1.4 Castel SRL

- 7.1.5 Sanhua USA

- 7.1.6 Curtiss-Wright Corporation

- 7.1.7 Danfoss A/S

- 7.1.8 Emerson Electric Co

- 7.1.9 Georg Fischer Ltd

- 7.1.10 Flowserve Corporation

- 7.1.11 Hitachi Ltd

- 7.1.12 Honeywell International Inc.

- 7.1.13 KITZ Corporation

- 7.1.14 Mueller Water Products Inc