|

市場調查報告書

商品編碼

1403829

震動監測 -市場佔有率分析、行業趨勢和統計、2024-2029 年成長預測Vibration Monitoring - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029 |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

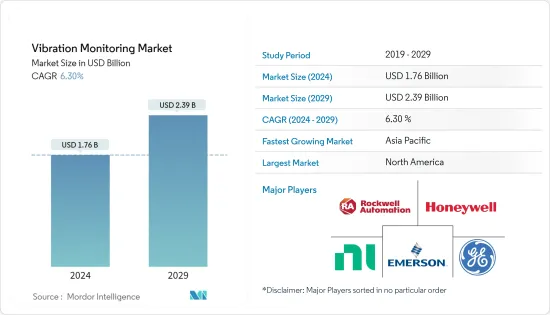

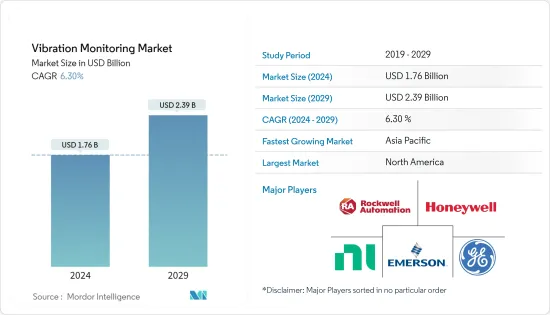

震動監測市場規模預計到 2024 年為 17.6 億美元,預計到 2029 年將達到 23.9 億美元,在預測期內(2024-2029 年)複合年成長率為 6.30%。

由於比生產流程更簡化的維護流程具有最佳化潛力,機械維護產業正在不斷成長。

主要亮點

- 震動監測是預測性維護的一個重要方面,主要用於旋轉設備,如蒸氣渦輪和燃氣渦輪機機、馬達、泵浦、壓縮機、造紙機、軋延、工具機和工具機。用於評估設備的運作狀況和機械狀況。震動分析可以在問題變得嚴重並導致意外停機之前發現問題。這可以透過連續或以指定間隔監測機器震動來實現。

- 震動狀態監測設備測量旋轉和往復機械的震動程度。感測器收集頻率和振幅資訊來測量機器震動模式。震動監測對於追蹤和分析齒輪和軸承等機械部件的狀況變化以及預測設備和零件故障至關重要。

- 與物聯網 (IoT) 相關的先進技術和服務的引入正在改變大多數工業應用。新參與企業和傳統進入者提供改變商業模式的創新解決方案的機會越來越多,旨在實現工廠自動化和工業智慧維護,創造更多創新的工作環境,這是透過努力產生的。由於使用狀態監測進行預防性維護,震動監測市場預計將出現強勁成長。

- 化學、石油和天然氣、電力和石化、水泥和製藥等行業必須遵守嚴格的國際政策,管理流程效率、人體工學和員工安全。製造過程會產生許多有毒氣體和化學物質,包括多環芳烴、乙烯、苯、丙烯、硫化氫、丁二烯、丁烷和硫,取決於產品。因此,員工安全已成為重中之重,震動監測正在蓬勃發展。

- 這種重要性促使各行業做出特別努力來保護其機械。使用狀態監測進行故障識別的主要好處是,負責人可以採取補救措施,以避免或降低維修成本,提高機器安全性,從而提高人身安全。市場成長受到各種關鍵因素的推動,包括機器狀態監測中無線系統的接受度不斷提高、自動化狀態監測技術的普及和智慧工廠的普及,以及用於狀態監測的安全雲端運算平台的出現。

- 技術專長的存在可以改善整體市場成長。此外,由於管理機構施加的道德考慮以及需要熟練的技術資源來進行可操作的資料分析,市場面臨限制。此外,由於偏遠地區缺乏專業知識以及震動監測系統與其他維護方法整合的趨勢不斷增加,預計市場在整個預測期內將面臨挑戰。

- 由於COVID-19的爆發,遠端操作的需求大幅增加。 2020年第一季,全球多家工業通訊企業收益成長大幅下滑。隨著經濟持續復甦和遠端控制需求的增加,市場變得越來越活躍,導致不需要人工監督的高度自動化系統的引入。

震動監測市場趨勢

石油和天然氣佔據主要市場佔有率佔有率

- 石油和天然氣業務在惡劣的操作環境下營運,包括海上鑽井和石化精製。機械故障會造成嚴重的經濟和環境後果。因此,在世界許多地區,檢測和預防不可預測的石油和天然氣機械及零件問題是強制性的。因為預測性維護技術透過最佳化維護計劃和提高生產力來幫助降低營運成本。

- 石油和天然氣產業處於採用創新技術的最前沿,以在快速發展的(物聯網)形勢中最佳化營運、提高效率並確保安全。該行業受到嚴格的監管標準,以確保營運安全和環境保護。震動監測是幫助企業遵守這些法規的主動措施。透過利用震動感測器並採取主動維護方法,石油和天然氣產業可以最佳化資產性能、提高安全性並顯著節省成本。

- 石油和天然氣產業預計將主導不斷擴大的市場。能源電力產業包括煤炭、核能、礦產、無污染燃料領域。已開發國家和開發中國家政府和私營部門在替代能源和電力源的支出不斷增加,導致安裝更多額外的能源和發電廠,加劇了對震動監測程序的需求。例如,2022年3月,印度石油公司董事會核准對Numaligarh石化計劃投資655億印度盧比(8.3949億美元)。此類計劃可能會增加震動監測系統的應用機會。

- 此外,2022 年 1 月,印度石油公司 (IOCL) 宣布了城市燃氣發行(CGD) 行業的擴張計劃,並正在考慮投資 700 億印度盧比(9.186 億美元)。此外,2022 年 5 月,ONGC 宣布計劃在 22-25 會計年度投資 40 億美元,擴大在印度的探勘活動。這些努力可能會進一步加速所研究市場的成長。

- 震動監測解決方案在石油和天然氣行業非常重要,因為它們可確保生產機械的運作並最大限度地減少停機時間、降低營運成本並提高生產力和財務回報。震動監測系統透過減少非計劃性運作和最佳化機器性能來降低維護和維修成本。

- 預計未來幾年對地下震動監測和控制系統的需求將大幅增加,以提高盈利並減少上游業務的停機時間。據日本經濟產業省稱,2022年日本從阿拉伯聯合大公國進口的原油將超過6,030千萬公升。其中大部分(約 3,000 萬千公升)來自穆爾班油田,其次是達斯島(Das Island)約 1,770 萬千公升。美國、沙烏地阿拉伯、阿拉伯聯合大公國等國未來的探勘和鑽探計劃預計將進一步擴大地下震動監測和控制系統的使用。

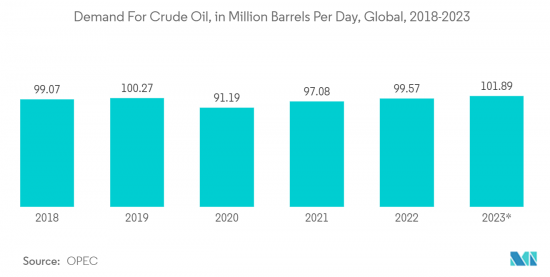

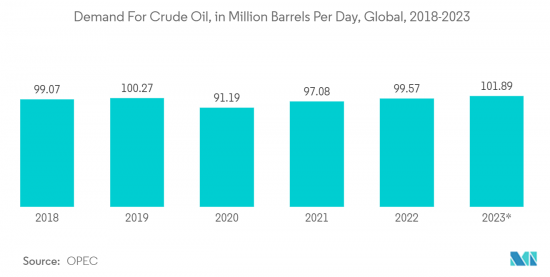

- 此外,根據OPEC的數據,2022年國際原油消費量預計將達到9,957萬桶/日,若算上生質燃料,2023年國際原油消費量將增加至1,0189萬桶/日。此外,震動監測在石油和天然氣行業的採用率很高。這用於預測分析,幫助製造商提高生產力並最大限度地提高營運效率。在石油和天然氣領域,需要進行狀態監測以對關鍵機械震動分析,以管理和防止因意外機器故障而導致的意外停機。

亞太地區市場將實現顯著成長

- 中國是全球重要的製造中心,也是世界上人口最多的國家,正在增加對電力和基礎設施領域的投資。中國政府先前宣布投資780億美元興建110座核能發電廠,預計2030年運作。這些進步預計將增加採用新興技術的潛力,以促進基於狀態的監測,例如震動監測解決方案。

- 電力、石油和天然氣、水泥、化學和石化以及汽車公司對預測性維護和震動監測技術的採用和認知不斷提高,再加上「中國製造 2025」等政府雄心勃勃的目標,可能會維持對震動監測的需求預測期內亞太地區。

- 儘管碳氫化合物能源價格下降,中國石油天然氣集團公司(中石油)等中國國家石油公司仍繼續專注於石油和天然氣探勘活動,以實現能源獨立。預計此類活動將推動對震動監測解決方案的強勁需求,以監測和促進石油和天然氣設備和基礎設施的維護。中國擁有世界上最大的頁岩油氣蘊藏量,並致力於透過與石油和天然氣公司成立合資企業來開發這些蘊藏量。

- 震動監測是預測性維護計畫的重要組成部分。定期檢查和監控油氣泵的狀況可以讓您在潛在問題導致故障之前識別並解決它們,避免計劃外停機和不必要的維修,可以節省您的時間和金錢。增加對所研究市場中各種應用的投資可能會進一步推動成長。 IBEF預計,2023年1月印度液化天然氣進口量預計為22.66億立方公尺(MMSCM)。 IEA預計,到2024年,印度天然氣消費量預計將成長25 BCM,年均成長率為9%。

- 印度擁有世界上最大的汽車市場之一。據 SIAM 稱,2023 會計年度印度汽車銷量約為 2,120 萬輛。印度汽車工業商協會(SIAM)的報告顯示,2022年6月國內小客車批發量成長2.2%至327萬輛,摩托車銷量成長1.7%至1,330萬輛。此外,政府的目標是到2030年將公車的電動車普及提高到40%,私家車的電動車普及率達到30%,商用車的電動車普及率達到70%。因此,隨著汽車產業的崛起和銷售能力的增強,該領域對震動監測的需求預計將會增加。

- 預防性保養是食品和飲料行業的關鍵要求。此外,震動監測可以有效避免停機,從根本上識別機器健康狀況,預測即將發生的設備故障,並透過主動糾正來最大限度地降低能源成本。食品業投資的增加預計將為市場和供應商創造豐富的前景,以滿足需求。

- 例如,根據(MFDS)的數據,2022年韓國食品工業總產值約佔該國GDP的3.15%,較前一年的2.91%略有上升。此外,韓國還計劃增強當地食品工業五個關鍵部門的活力,作為 2030 年食品工業價值翻倍目標的一部分。同樣,根據韓國食品和藥物管理局的數據,韓國食品工業近年來經歷了顯著成長,年成長率約為 8.1%。這些能力可能有助於市場需求。

震動監測產業概況

震動監測市場競爭激烈。該市場的重要參與企業包括羅克韋爾自動化公司、美國國家儀器公司、通用電氣公司、艾默生電氣公司、霍尼韋爾國際公司、Bruel &Kjaer 聲音與振動測量公司等。公司建立多種合作夥伴關係,透過推出新產品來競爭並擴大市場佔有率。

2022年8月,專注於電池生產、汽車和能源儲存技術的脫碳領域創新解決方案供應商羅克韋爾自動化宣布將與Bravo汽車公司合作。汽車製造商依靠噪音震動監測和聲振粗糙度測試來最佳化車輛性能並維持其車輛目錄的舒適度標準。

2022 年 2 月,倍加福開始提供一系列震動感測器,以對低頻或高頻範圍內的震動速度和加速度進行可靠的測量。倍加福的震動感測器已獲得 SIL 2 許可,測量能力高達每分鐘 128 毫米,與競爭產品相比,還可自動偵測滾珠軸承的狀態。由於其堅固的外殼封裝了電子裝置,該感測器以其免維護操作和長使用壽命而令人印象深刻。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間的敵對關係

- 宏觀經濟走勢對市場的影響

第5章市場動態

- 市場促進因素

- 提高預測性維護和分析強化的意識

- 無線系統在震動監測中的使用增加

- 市場挑戰

- 缺乏客製化且初始投資較高

第6章市場區隔

- 按類型

- 硬體

- 加速計

- 車速表

- 位移計

- 其他硬體

- 軟體

- 服務

- 硬體

- 按最終用戶產業

- 車

- 油和氣

- 能源/電力

- 礦業

- 食品和飲料

- 化學

- 其他最終用戶產業

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東/非洲

第7章競爭形勢

- 公司簡介

- Rockwell Automation Inc.

- National Instruments Corporation

- General Electric Corporation

- Emerson Electric Company

- Honeywell International Inc.

- Bruel & Kjaer Sound & Vibration Measurement

- Meggit PLC

- Analog Devices Inc.

- SPM Instrument AB

- Schaeffler AG

- STMicroelectronics

- PCB Piezotronics Inc.

- Banner Engineering

- SKF

- Azima DLI Corporation

- Data Physics Corporation

第8章投資分析

第9章市場的未來

The Vibration Monitoring Market size is estimated at USD 1.76 billion in 2024, and is expected to reach USD 2.39 billion by 2029, growing at a CAGR of 6.30% during the forecast period (2024-2029).

The machine maintenance industry has experienced growth due to the optimization potential of maintenance processes, which have become more streamlined than production processes.

Key Highlights

- Vibration monitoring is a critical aspect of predictive maintenance, and it is primarily used in rotating equipment such as steam and gas turbines, motors, pumps, compressors, paper machines, rolling mills, machine tools, and gearboxes. It is used to evaluate the operational and mechanical condition of equipment. Vibration analysis can detect developing problems before they become too severe and cause unscheduled downtime, which can be achieved by continuously monitoring machine vibrations or at predetermined intervals.

- Vibration condition monitoring equipment measures the vibration levels of rotating and reciprocating machinery. Sensors collect information on frequency and amplitude to measure the vibration patterns of machinery. Vibration monitoring is essential for tracking and analyzing changes in the condition of machinery parts, such as gears and bearings, and predicting equipment or part failure.

- The introduction of advanced technologies and services associated with the Internet of Things (IoT) is transforming most industrial applications. The opportunities for new entrants and traditional players to offer innovative solutions that change the business models are created by initiatives aimed at the automation of factories and implementing industrial smart maintenance, as well as efforts towards creating more innovative working environments. The vibration monitoring market is expected to grow strongly, thanks to the use of condition monitoring for preventive maintenance.

- Industries such as chemical, oil and gas, power and petrochemical, cement, and pharmaceuticals must abide by the stringent international policies that dictate process efficiency, ergonomics, and employee safety. Many toxic gasses and chemicals, such as polyaromatic hydrocarbons, ethylene, benzene, propylene, hydrogen sulfide, butadiene, butane, and sulfur, are generated as byproducts during the manufacturing processes. Therefore, vibration monitoring is gaining momentum as employee safety has gained paramount prominence.

- This significance has pushed various verticals to make extra efforts to protect their machinery. The main benefit of fault identification using condition monitoring is to allow personnel to take remedial action to avoid or reduce repair costs and increase machinery safety, thus improving human safety. The growth of the market is anticipated to be driven by various key factors, such as the rising acceptance of wireless systems in machine condition monitoring, the rising popularity of automated condition monitoring technologies and smart factory penetration, and the emergence of secure cloud computing platforms utilized in condition monitoring.

- The market's overall growth could be improved by the presence of technical expertise. Additionally, the market faces limitations due to ethical considerations imposed by governing bodies and a need for proficient technological resources for practical data analysis. Moreover, the market is expected to encounter challenges throughout the projected period, including the unavailability of expertise in remote areas and the increasing trend of integrating vibration monitoring systems with other maintenance practices.

- There has been a significant increase in the demand for remote operations due to the COVID-19 outbreak. A major decline in revenue growth for a number of industry communication companies worldwide took place during the 1st quarter of 2020. With the continued recovery of the economy and the growing need for remote operations, the market is becoming more and more active, leading to the adoption of highly automated systems that do not require any human oversight.

Vibration Monitoring Market Trends

Oil and Gas to Hold Significant Market Share

- Oil and gas operations operate in extreme operating environments, such as offshore drills and petrochemical refineries. There are severe financial and environmental consequences for any mechanical defeat. Thus, the detection and prevention of unpredictable oil and gas machinery and component issues are mandated in many parts of the world. The flammable oil price environment expands the adoption of predictive maintenance technologies, as these help organizations cut operational expenses by optimizing maintenance scheduling and driving productivity.

- The oil and gas industry is at the forefront of adopting innovative technologies to optimize operations, enhance efficiency, and ensure safety in the rapidly evolving landscape of the (IoT). This industry is subject to strict regulatory standards to ensure operational safety and environmental protection. Vibration monitoring is a proactive measure that helps companies comply with these regulations. By leveraging vibration sensors and adopting a proactive approach to maintenance, the oil and gas industry can optimize asset performance, enhance safety, and achieve substantial cost savings.

- The oil and gas industry is anticipated to dominate the expanding Market. The energy and power industry includes several segments, such as coal, nuclear power, minerals, and clean fuels. The raised spending from the government and the private sector on alternative energy and power sources in developed and developing nations is resulting in the installation of more additional energy and power plants, thus fueling the need for vibration monitoring procedures. For instance, in March 2022, the Board of Oil India approved an investment of INR 6,555 crore (USD 839.49 million) for the Numaligarh petrochemical project. Such projects will enhance the application opportunities for vibration monitoring systems.

- In addition, in January 2022, Indian Oil Corp. Ltd. (IOCL) announced plans to extend its city gas distribution (CGD) industry, looking to invest INR 7,000 crore (USD 918.6 million). Further, in May 2022, ONGC announced plans to invest USD 4 billion from FY22-25 to increase its exploration efforts in India. Such initiatives may further propel the studied market growth.

- Vibration monitoring solutions are critical in the oil and gas industry as they ensure that the production machinery is operational and downtime is minimized, lowering operating costs and increasing productivity and monetary gains. A vibration monitoring system aids in the reduction of unplanned outages and the optimization of machine performance, thus reducing maintenance and repair costs.

- The demand for downhole vibration monitoring and control systems is expected to increase significantly in the coming years to increase profitability and reduce downtime in upstream operations. According to METI (Japan), in 2022, the import volume of crude oil from the United Arab Emirates to Japan reached more than 60.3 million kiloliters. The majority of nearly 30 million kiloliters comprised oil from the Murban oil field, followed by oil from Das Island at around 17.7 million. The applications of the downhole vibration monitoring control system have been expected to grow further with upcoming exploration and drilling projects in countries such as the United States, Saudi Arabia, and the United Arab Emirates.

- In addition, according to OPEC, the international Crude oil consumption reached 99.57 million barrels a day in 2022, which included biofuels is projected to grow to 101.89 million barrels per day in 2023. Furthermore, the adoption of vibration monitoring is high in the oil and gas sectors. It is used for predictive analysis, which helps manufacturers increase their productivity and maximize operational efficiency. Condition monitoring is required for vibration analysis on vital machines to manage and prevent unexpected shutdowns due to unforeseen machinery failure within the oil and gas sector.

Asia-Pacific to Witness Significant Market Growth

- China is a prominent global manufacturing center with the largest population globally, and it is increasing investments in the power and infrastructure sectors. The Chinese government has previously declared investments worth USD 78 billion to construct 110 nuclear power plants, which are scheduled to become operational by 2030. These advancements are anticipated to expand the potential for adopting contemporary technologies, such as vibration monitoring solutions, to facilitate condition-based monitoring.

- Increasing adoption and awareness of predictive maintenance and vibration monitoring technologies in the power, oil and gas, cement, chemical and petrochemical, and automotive firms, coupled with government ambitions, such as 'Made in China 2025', may design sustained demand for vibration monitoring in Asia-Pacific during the forecast period.

- Despite the falling hydrocarbon energy prices, there is a continued focus on oil and gas exploration activities to achieve energy self-sufficiency by NOCs, such as CNPC in China. These activities are anticipated to create a robust demand for vibration-monitoring solutions to monitor and facilitate the maintenance of oil and gas equipment and infrastructures. China has the most significant shale oil and gas reserve worldwide and focuses on tapping the same through joint ventures with oil and gas companies.

- Vibration monitoring is an integral part of a predictive maintenance program. Regularly inspecting and monitoring the condition of oil and gas pumps can help identify and address potential problems before they cause failure, thus saving time and money by avoiding unplanned outages and unnecessary repairs. Increasing investment in various applications in the studied market may further propel growth. According to IBEF, India's LNG import was predicted at 2,266 million metric standard cubic meters (MMSCM) in January 2023. According to IEA, natural gas consumption in India is expected to grow by 25 BCM, recording an average annual boost of 9 percent until 2024.

- India boasts one of the largest automotive markets globally. As per SIAM, approximately 21.2 million vehicles were sold in India during FY 2023. In June 2022, domestic passenger vehicle wholesales witnessed a 2.2 percent surge, reaching 3.27 lakh units, while two-wheeler sales experienced a 1.7 percentage increase, totaling 13.30 lakh units, as reported by the Society of Indian Automobile Manufacturers (SIAM). Additionally, the government aims to achieve a 40 percent electric vehicle sales penetration for buses, 30 percentage for private cars, and 70 percent for commercial vehicles by 2030. Therefore, with the rising automotive industry and growing sales capabilities, the need for vibration monitoring in the sector is expected to increase.

- Preventive maintenance has emerged as a crucial requirement in the Food and Beverage Industry. Furthermore, vibration monitoring can effectively avert downtime, identify fundamental machine health, and minimize energy expenses by anticipating impending equipment malfunctions and rectifying them proactively. The escalating investments in the food sector are expected to generate abundant prospects for the market and vendors to cater to the demand.

- For instance, According to the (MFDS), the food industry's total production value in South Korea accounted for approximately 3.15 percent of the country's GDP in 2022, a slight increase from 2.91 percent in the previous year. Additionally, South Korea aims to enhance the vitality of five significant sectors within the local food industry as part of its 2030 objective to double the sector's value. Similarly, according to the Korea Food and Drug Administration, the Korean food industry has experienced significant growth in recent years, with an annual increase of approximately 8.1 percent. These capabilities will contribute to the market's demand.

Vibration Monitoring Industry Overview

The vibration monitoring market is significantly competitive. Some significant players in the Market are Rockwell Automation Inc., National Instruments Corporation, General Electric Corporation, Emerson Electric Company, Honeywell International Inc., and Bruel & Kjaer Sound & Vibration Measurement. The companies are increasing their market share by forming multiple partnerships and introducing new products to earn a competitive edge.

In August 2022, Rockwell Automation Inc., a company providing innovative solutions in the area of decarbonization focused on battery production, vehicles, and energy storage technologies, teamed up with Bravo Motor Company, a California firm that offers an array of services to businesses. Automotive manufacturers rely on noise vibration monitoring and harshness testing to optimize vehicle performance and keep a standard of comfort across their automobile catalog.

In February 2022, Pepperl+Fuchs started offering a range of vibration sensors to perform reliable measures of vibration velocity and acceleration in lower or high-frequency fields. Pepperl+Fuchs vibration sensors are licensed to SIL 2, and they have a large measurement capacity of up to 128 mm per minute, as well as an automated state detecting for ball bearings compared with competing products. The sensors impress with a maintenance-free operation and long service life due to their robust housing encased in electronics.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of Macroeconomic Trends on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Awareness About Predictive Maintenance and Augmenting it with Analytics

- 5.1.2 Increasing Use of Wireless Systems for Vibration Monitoring

- 5.2 Market Challenges

- 5.2.1 Lack of Customization and High Initial Investment

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Hardware

- 6.1.1.1 Accelerometer

- 6.1.1.2 Velocity

- 6.1.1.3 Displacement

- 6.1.1.4 Other Hardware

- 6.1.2 Software

- 6.1.3 Services

- 6.1.1 Hardware

- 6.2 By End-user Industry

- 6.2.1 Automotive

- 6.2.2 Oil and Gas

- 6.2.3 Energy and Power

- 6.2.4 Mining

- 6.2.5 Food and Beverage

- 6.2.6 Chemicals

- 6.2.7 Other End-user Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia Pacific

- 6.3.4 Latin America

- 6.3.5 Middle-East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Rockwell Automation Inc.

- 7.1.2 National Instruments Corporation

- 7.1.3 General Electric Corporation

- 7.1.4 Emerson Electric Company

- 7.1.5 Honeywell International Inc.

- 7.1.6 Bruel & Kjaer Sound & Vibration Measurement

- 7.1.7 Meggit PLC

- 7.1.8 Analog Devices Inc.

- 7.1.9 SPM Instrument AB

- 7.1.10 Schaeffler AG

- 7.1.11 STMicroelectronics

- 7.1.12 PCB Piezotronics Inc.

- 7.1.13 Banner Engineering

- 7.1.14 SKF

- 7.1.15 Azima DLI Corporation

- 7.1.16 Data Physics Corporation