|

市場調查報告書

商品編碼

1132520

工業 4.0 實施分析(2022 年)Industry 4.0 Adoption Report 2022 |

||||||

在本報告中,我們分析了全球製造業中工業 4.0 的實施情況,並根據對 500 名製造商高級管理人員的採訪,調查了以下項目。

- 智能工廠戰略的介紹現狀和工業4.0相關的7個戰略(按地區和行業)

- 受訪者 KPI(關鍵績效指標)和改進計劃的重要性(基於 27 個 KPI 列表項)

- 業務決策者和一致性:按框架/按聯盟

- 投資執行/計劃狀態:15 家智能製造公司和 16 種互聯產品的用例(按地區/行業)

- 參與智能工廠項目的供應商

- 最大的技術挑戰:受訪者面臨的問題

- 其他

本報告中回答的問題

- 對於製造商而言,最重要的智能工廠 KPI 是什麼?

- 在運營和產品中採用最多的工業 4.0 用例有哪些?

- 誰是工業 4.0 項目的決策者?

- 哪些技能差距阻礙了製造商從概念驗證 (PoC) 轉向商業部署?

- 製造商如何採購他們的軟件以及他們在哪裡托管?

- 未來三年製造商計劃如何購買軟件?

- 公司在哪裡運行其關鍵工作負載?

- 工業 4.0 項目中最常涉及哪些類型的供應商?

- 保護生產車間的最常用技術有哪些?

- 製造商如何保護他們的互聯產品?

本報告從以下七個方面觀察智能工廠技術的實施情況。

- 1. 策略

- 2. KPI(關鍵績效指標)

- 3. 決策制定和框架

- 4. 用例採用

- 5. 部署到雲端邊緣

- 6. 供應商摘要

- 7. 任務

本報告中的主要公司

|

|

內容

第 1 章執行摘要

第 2 章工業 4.0 概述

第三章分析技術

第 4 章工業 4.0 戰略

第 5 章智能工廠 KPI(關鍵績效指標)

第 6 章決策和框架

第 7 章採用工業 4.0 用例

- a.概述

- b. 詳細信息:智能製造的用例

- c. 詳細信息:智能產品的用例/功能

第 8 章。部署方法(雲和邊緣)

第 9 章供應商

第 10 章:任務

第十一章附錄

第12章 IoT Analytics

217-page report on the state of Industry 4.0 adoption based on the input from 500 senior executives in manufacturing companies including:

- Implementation state of smart factory strategy and 7 more strategies related to industry 4.0 across different regions and industries

- Importance and planned improvement of respondents' KPIs across a list of 27 different KPIs

- The decision makers and alignment of companies with different frameworks/consortia

- Adoption and planned investment for 15 smart manufacturing and 16 connected products use cases across regions and industries

- Vendors involved in smart factory projects

- Biggest technical challenges faced by respondents

- And more

The “Industry 4.0 Adoption Report 2022” is part of IoT Analytics' ongoing coverage of industrial IoT. The information presented in this report is based on extensive research and an extensive survey of 500 senior executives in manufacturing companies.

The purpose of this document is to inform interested parties of the current state of adoption of Industry 4.0 use cases across manufacturers through the IoT Analytics research lens.

Questions answered in this report:

- What smart factory KPIs are most important to manufacturers?

- What are the most adopted Industry 4.0 use cases for operations and products?

- Who are the decision makers in Industry 4.0 projects?

- What are some of the skill gaps that inhibit manufacturers from moving from proof of concept (PoC) to commercial deployment?

- How do manufacturers procure software and where do they host it?

- How do manufacturers plan to purchase software in the next three years?

- Where do companies run key workloads?

- What kind of vendors are most often involved in Industry 4.0 projects?

- What are the most common techniques to secure the shop floor?

- How do manufacturers secure connected products?

At a glance:

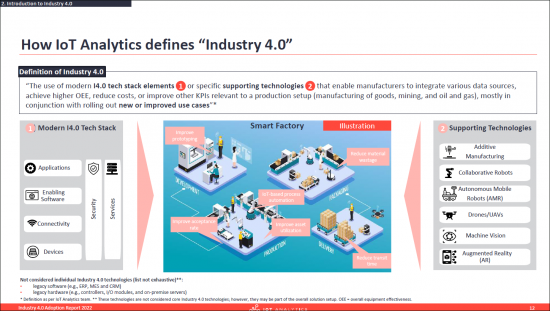

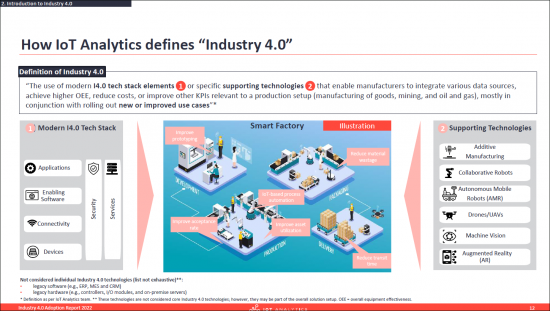

Definition (as per IoT Analytics)

"The use of modern I4.0 tech stack elements (1) or specific supporting technologies (2) that enable manufacturers to integrate various data sources, achieve higher OEE, reduce costs, or improve other KPIs relevant to a production setup (manufacturing of goods, mining, and oil and gas), mostly in conjunction with rolling out new or improved use cases."

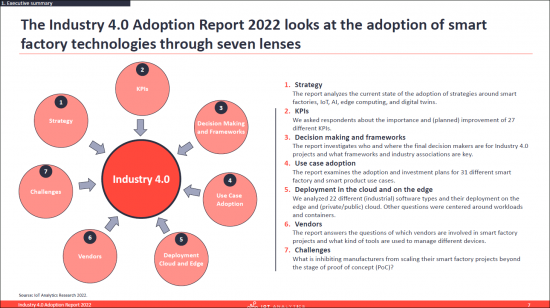

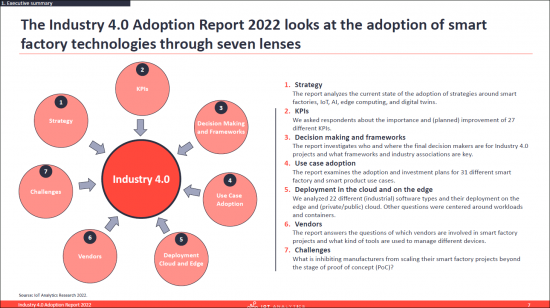

The Industry 4.0 Adoption Report 2022 looks at the adoption of smart factories technologies through seven lenses.

- 1. Strategy

- 2. KPIs

- 3. Decision makind and frameworks

- 4. Use case adoption

- 5. Deployment in the cloud and on the edge

- 6. Vendors

- 7. Challenges

This report includes statistics on the progress in the implementation of 8 different strategies across regions, industries, and company sizes.

The results show the importance each KPI has for the smart factory strategy across a list of 27 KPIs.

This publication includes a detailed breakdown of the final decision makers by decision type.

This report includes extended statistics for smart manufacturing and connected products use cases, including adoption rate and planned investments across regions and industries.

IoT Analytics includes detailed deep dives into the adoption and planned investment for each of the:

- 15 smart manufacturing use cases

- 16 smart product use cases

Selected companies mentioned in the report:

|

|

Table of Contents

1. Executive summary

2. Introduction to Industry 4.0

3. Methodology

4. Industry 4.0 strategy

5. Smart factory KPIs

6. Decision making and frameworks

7. Adoption of Industry 4.0 use cases

- a. Overview

- b. Deep dive: Smart manufacturing use cases

- c. Deep dive: Smart product use cases/features