|

市場調查報告書

商品編碼

1445934

金屬基複合材料 - 市場佔有率分析、產業趨勢與統計、成長預測(2024 - 2029 年)Metal Matrix Composites - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

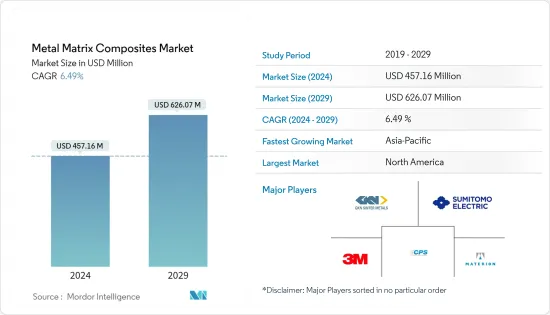

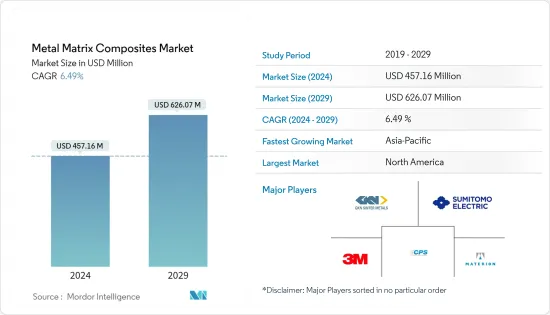

金屬基複合材料市場規模預計到2024年為4.5716億美元,預計到2029年將達到6.2607億美元,在預測期內(2024-2029年)CAGR為6.49%。

在 2020 年新型冠狀病毒 (COVID-19) 大流行期間,全國實施了封鎖和社交距離規定,導致供應鏈中斷和各個製造業關閉。這對市場產生了負面影響。然而,在後疫情時期,市場正重回正軌。

主要亮點

- 航空航太和國防工業對輕質材料的需求不斷成長,以及金屬基複合材料優於金屬的性能是市場的主要促進因素。

- 然而,複雜的製造過程可能會阻礙市場的成長。

- 機車行業的不斷成長的使用和電動汽車的日益普及預計將為市場提供新的機會。

- 北美市場佔有率最高。然而,預計亞太地區將在預測期內主導市場。

金屬基複合材料市場趨勢

電氣和電子領域成長最快

- 金屬基複合材料用於各種電氣和電子元件和設備。例如,鋁-石墨複合材料因其優異的導熱性、可調的熱膨脹係數和低密度而被用於電力電子模組。

- SiC 增強的 Al 和 Cu 具有優異的熱物理性能,如低熱膨脹係數 (CTE)、高導熱率和改善的機械性能,例如更高的比強度、更好的耐磨性和特定模數。

- 由於具有高導熱性,dymalloy(一種含有 55% 鑽石顆粒(以體積計)的銅銀合金基體)被用作電子產品中高功率、高密度多晶片模組的基材。

- 此外,PRMMC(顆粒增強金屬基複合材料)具有高體積分數,在電子行業中有廣泛的應用,包括散熱器面板、功率半導體封裝、微波模組、電池套、黑盒子外殼、印刷電路等。板散熱器等。

- 根據日本電子資訊科技產業協會(JEITA)發布的全球電子統計數據,預計2021年全球電子資訊產業產值將年增11%,達到33,602億美元,2022年產值也將年增11%。成長5%,達到35,366 億美元。

- 手機、攜帶式計算設備、遊戲系統和其他個人電子設備的生產將繼續激發對電子元件的需求,預計這將推動對金屬基複合材料的需求。

- 由於上述所有因素,在預測期內,對電氣和電子設備的需求可能會增加所研究市場的需求。

亞太地區將主導市場

- 亞太地區佔全球電子產品產量的 70% 以上,韓國、日本和中國等國家為全球各產業製造各種電氣元件和用品。

- 亞太地區2021年前9個月的汽車總產量為3,267萬輛,較2020年同期成長11%。

- 總體而言,中國、印度、日本和韓國等國家的需求持續成長可能會提振該地區的金屬基複合材料市場。

- 2021年12月,中國工業生產年增4.3%。因此,中國工業部門的擴張預計將有利於預測期內金屬基複合材料市場的成長。

- 根據中國工信部資料顯示,2022年前5個月電子資訊製造業維持穩定成長,年營業收入2,000萬元以上(約300萬美元),較去年同期成長9.9%。

- 政府啟動了 PLI 計劃,隨著製造商在印度增加產量,該計劃可能會在五年內提供 55 億美元的激勵措施。這可能會促進該國電子產品的生產,從而有利於金屬基複合材料的需求。

- 在航空航太領域,據印度品牌股權基金會(IBEF)稱,未來四年,印度航空業預計將獲得 3,500 億印度盧比(49.9 億美元)的投資。

- 此外,2022年前四個月,日本電子產業的產量為36,564.4億日圓(326億美元),與2021年同期相比成長約0.2%。

- 上述因素可能會增加亞太地區應用產業對金屬基複合材料的需求。

金屬基複合材料產業概述

全球金屬基複合材料市場本質上是部分分散的,該行業存在大量全球和本地參與者。市場的主要參與者包括 GKN Sinter Metals Engineering GmbH、Materion Corporation、3M、Sumitomo Electric Industries Ltd 和 CPS Technologies Corporation 等。

額外的好處:

- Excel 格式的市場估算 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章:簡介

- 研究假設

- 研究範圍

第 2 章:研究方法

第 3 章:執行摘要

第 4 章:市場動態

- 促進要素

- 航太和國防工業對輕質材料的需求不斷增加

- 金屬基複合材料優於金屬的性能

- 限制

- 製造流程複雜

- 其他限制

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 消費者的議價能力

- 新進入者的威脅

- 替代產品和服務的威脅

- 競爭程度

- 技術簡介

第 5 章:市場區隔(市場價值規模)

- 類型

- 鎳

- 鋁

- 耐火

- 其他類型

- 填料

- 碳化矽

- 氧化鋁

- 碳化鈦

- 其他填料

- 最終用戶產業

- 汽車及機車

- 電氣和電子

- 航太和國防

- 工業的

- 其他最終用戶產業

- 地理

- 亞太

- 中國

- 印度

- 日本

- 韓國

- 亞太其他地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 西班牙

- 歐洲其他地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 中東和非洲其他地區

- 亞太

第 6 章:競爭格局

- 併購、合資、合作與協議

- 市場排名分析

- 領先企業採取的策略

- 公司簡介

- 3A Composites

- 3M (Ceradyne Inc.)

- ADMA Products Inc.

- CPS Technologies Corp.

- DAT Alloytech

- Denka Company Limited

- GKN Sinter Metals Engineering GmbH

- Hitachi Metals Ltd

- Materion Corporation

- MTC Powder Solutions AB

- Plansee Group

- Sumitomo Electric Industries Ltd

- Thermal Transfer Composites LLC

- TISICS Ltd

第 7 章:市場機會與未來趨勢

- 在機車行業中的應用不斷成長

- 電動車的普及率不斷提高

The Metal Matrix Composites Market size is estimated at USD 457.16 million in 2024, and is expected to reach USD 626.07 million by 2029, growing at a CAGR of 6.49% during the forecast period (2024-2029).

During the pandemic period in 2020 due to COVID-19, there were nationwide lockdowns and social distancing mandates which led to supply chain disruption and the closure of various manufacturing industries. This impacted the market negatively. However, in the post-pandemic period, the market is getting back on track.

Key Highlights

- Increasing demand for lightweight materials in the aerospace and defense industry and superior properties of metal matrix composites over metals are the major driving factors for the market.

- However, the complicated manufacturing process is likely to hinder the market growth.

- Growing use in the locomotive industry and increasing adoption of electric vehicles are expected to provide new opportunities for the market.

- North America accounted for the highest market share. However, Asia-Pacific is projected to dominate the market during the forecast period.

Metal Matrix Composites Market Trends

Electrical and Electronics Segment to Register Fastest Growth

- Metal matrix composites are used in various electrical and electronic components and devices. For instance, aluminum-graphite composites are employed in power electronic modules due to their excellent thermal conductivity, tunable coefficient of thermal expansion, and low density.

- Al and Cu reinforced by SiC are used in various industries due to their excellent thermo-physical properties, such as low coefficient of thermal expansion (CTE), high thermal conductivity, and improved mechanical properties, such as higher specific strength, better wear resistance and specific modulus.

- Because of its high heat conductivity, dymalloy, a copper-silver alloy matrix containing 55% diamond particles (by volume), is utilized as a substrate for high-power, high-density multi-chip modules in electronics.

- In addition, PRMMCs (particulate reinforced metal matrix composites), with a high-volume fraction, have a wide range of applications in the electronics industry, including radiator panels, power semiconductor packages, microwave modules, battery sleeves, black box enclosures, printed circuit board heat sinks, and others.

- According to the global electronics statistics published by the Japan Electronics and Information Technology Industries Association (JEITA), the Production by the global electronics and IT industries is expected to grow 11% year on year in 2021 to reach USD 3,360.2 billion, with 2022 production too lifting 5% to USD 3,536.6 billion.

- The production of cellular phones, portable computing devices, gaming systems, and other personal electronic devices will continue to spark the demand for electronic components, which is expected to boost the demand for metal matrix composites.

- Owing to all the factors mentioned above, the demand for electrical and electronic equipment is likely to increase the demand in the market studied during the forecast period.

Asia-Pacific Region to Dominate the Market

- Asia-Pacific accounts for more than 70% of global electronics production, with countries like South Korea, Japan, and China involved in manufacturing various electrical components and supplies to various industries globally.

- The Asia-Pacific region recorded 32.67 million of total automotive production in the nine months of 2021, an increase of 11% from the same period in 2020.

- Overall, the consistent growth in demand in countries like China, India, Japan, and South Korea is likely to boost the metal matrix composites market in the region.

- Industrial production in China increased by 4.3% year-on-year in December 2021. Thus, the expansion of the industrial sector in the country is anticipated to benefit the growth of the metal matrix composites market during the forecast period.

- According to China's data from the Ministry of Industry and Information Technology, the electronic information manufacturing sector maintained steady growth in the first five months of 2022. The value-added output of electronic information manufacturers with annual operating revenue of at least CNY 20 million (about USD 3 million) expanded 9.9 percent year-on-year during the period.

- The government launched the PLI scheme, which is likely to offer incentives as manufacturers increase production in India with USD 5.5 billion available over five years. This is likely to boost the production of electronics in the country, thus benefiting the demand for metal matrix composites.

- In the aerospace sector, according to the India Brand Equity Foundation (IBEF), the country's aviation industry is expected to witness INR 35,000 crore (USD 4.99 billion) investment in the next four years.

- Moreover, in the first four months of 2022, the production by the Japanese electronics industry accounted for JPY 3,656.44 billion (USD 32.60 billion), registering a growth rate of around 0.2% compared to the same period in 2021.

- The factors mentioned above are likely to ascend the demand for metal matric composites across the application industries in Asia-Pacific.

Metal Matrix Composites Industry Overview

The global metal matrix composites market is partially fragmented in nature, with the presence of a large number of global and local players in the industry. The major players in the market include GKN Sinter Metals Engineering GmbH, Materion Corporation, 3M, Sumitomo Electric Industries Ltd, and CPS Technologies Corporation, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Demand for Lightweight Materials in Aerospace and Defense Industry

- 4.1.2 Superior Properties of Metal Matrix Composites over Metals

- 4.2 Restraints

- 4.2.1 Compilicated Manufacturing Process

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

- 4.5 Technological Snapshot

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Type

- 5.1.1 Nickel

- 5.1.2 Aluminium

- 5.1.3 Refractory

- 5.1.4 Other Types

- 5.2 Fillers

- 5.2.1 Silicon Carbide

- 5.2.2 Aluminum Oxide

- 5.2.3 Titanium Carbide

- 5.2.4 Other Fillers

- 5.3 End-user Industry

- 5.3.1 Automotive and Locomotive

- 5.3.2 Electrical and Electronics

- 5.3.3 Aerospace and Defense

- 5.3.4 Industrial

- 5.3.5 Other End-user Industries

- 5.4 Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Italy

- 5.4.3.4 France

- 5.4.3.5 Spain

- 5.4.3.6 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 3A Composites

- 6.4.2 3M (Ceradyne Inc.)

- 6.4.3 ADMA Products Inc.

- 6.4.4 CPS Technologies Corp.

- 6.4.5 DAT Alloytech

- 6.4.6 Denka Company Limited

- 6.4.7 GKN Sinter Metals Engineering GmbH

- 6.4.8 Hitachi Metals Ltd

- 6.4.9 Materion Corporation

- 6.4.10 MTC Powder Solutions AB

- 6.4.11 Plansee Group

- 6.4.12 Sumitomo Electric Industries Ltd

- 6.4.13 Thermal Transfer Composites LLC

- 6.4.14 TISICS Ltd

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Growing Use in Locomotive Industry

- 7.2 Increasing Adoption of Electric Vehicles