|

市場調查報告書

商品編碼

1443940

金屬表面處理:市場佔有率分析、產業趨勢與統計、成長預測(2024-2029)Metal Finishing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

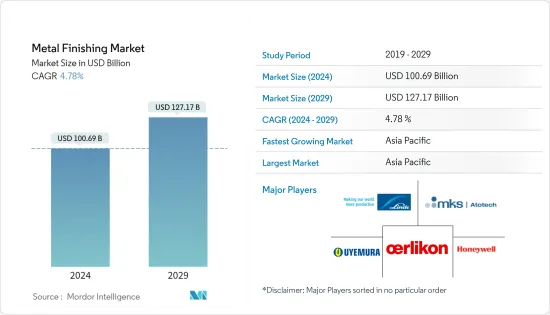

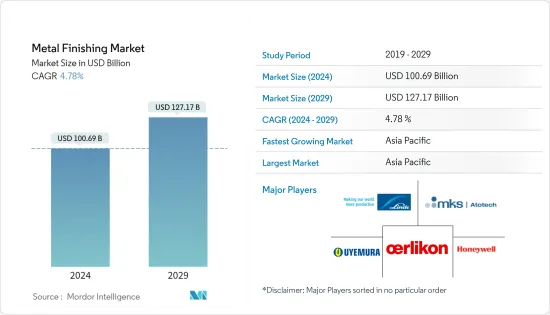

金屬表面處理市場規模預計到2024年為1006.9億美元,預計到2029年將達到1271.7億美元,在預測期內(2024-2029年)成長4.78%,以年複合成長率成長。

COVID-19 大流行對市場產生了負面影響。這是因為製造設施和工廠因封鎖和限制措施而關閉。供應鏈和運輸中斷造成了進一步的市場瓶頸。然而,隨著所研究市場的需求復甦,該產業在 2021 年出現復甦。

主要亮點

- 短期內,對耐用、耐磨和持久的金屬產品的需求不斷增加是推動市場成長的一些因素。

- 另一方面,對某些金屬表面處理化學品的環境法規以及塑膠替代金屬的增加預計將阻礙市場成長。

- 然而,從傳統溶劑型技術向新技術的過渡可能會在預測期內提供市場機會。

- 由於汽車、建築、電子和硬體等最終用戶行業的強勁需求,亞太地區主導了全球市場。

金屬表面處理市場趨勢

汽車產業佔市場主導地位

- 金屬表面處理市場的需求主要由汽車產業主導。金屬表面處理是為車輛金屬零件提供保護層最常用的方法之一。

- 金屬飾面用於車輛部件,例如引擎、其他引擎蓋下部件、動力方向盤系統、煞車部件和系統、空調部件和系統、底盤硬體、空調部件和燃油系統。

- 金屬表面處理還包括油漆和陶瓷塗布。許多大大小小的汽車零件都需要光滑的接觸表面以減少應力並且沒有毛邊和缺陷。這使得汽車引擎的表面摩擦和熱量更少,產生更多馬力並提高整體性能。

- 美國擁有世界主要汽車工業之一,佔國內生產總值(GDP)至少3%。 2022年,全國汽車產量近1,006萬輛,包括小客車和商用車,比2021年增加10%。因此,國內汽車產量的增加預計將產生汽車需求的上升。金屬表面處理市場。

- 在印度尼西亞,由於車輛排放氣體法規收緊、車輛安全性提高、車輛駕駛員輔助系統以及零售和電子商務領域物流快速成長,對輕型商用車的需求大幅增加。例如,根據 OICA 的數據,2022 年該國生產了約 1,60,171 輛輕型商用車,比 2021 年成長了 1%。預計這將推動金屬精加工市場的需求上升。該國的輕型商用車市場。

- 此外,在菲律賓,電子商務對商品的需求不斷增加,正在推動輕型商用車在物流中的使用,為國內輕型商用車市場的成長鋪平道路。許多電子商務和物流公司在該國不斷發展,進一步推動了輕型商用車市場的成長。例如,2022年國內輕型商用車產量達50,560輛,較2021年成長68%。

- 此外,馬來西亞放寬的行動限制令使該國許多經濟部門得以恢復營運,從而增強了景氣,並有助於包括商用車在內的新車生產。您需要它來經營您的業務。例如,馬來西亞2022年輕型商用車產量為52,085輛,較2021年成長48%。因此,預計這將支持該國輕型商用車金屬飾面的需求。

- 由於技術更先進的汽車的出現,金屬表面處理市場可能會長期成長。

亞太地區主導市場

- 在亞太地區,汽車產業投資和生產的增加、電氣和電子設備產量的增加以及重型機械需求的激增是推動金屬表面處理市場的一些關鍵因素。跨國公司推動了該地區工業部門的發展。

- 中國在亞太地區金屬表面處理市場佔有最大的市場佔有率。由於國內投資和建設活動的增加,金屬表面處理市場的需求預計在整個預測期內都會增加。近年來,中國一直是世界基礎建設的主要投資者之一,並做出了重要貢獻。例如,根據中國國家統計局(NBS)的數據,2022年中國建築業產值將達到27.63兆元(41.08581億美元),比2021年成長6.6%。

- 此外,由於物流和供應鏈的改善、企業活動的增加以及豐富的國內消費促進政策等因素促進了國內客車生產,中國也是最大的小客車小客車國之一。例如,根據OICA的數據,2022年中國小客車產量為23,836,083輛,較2021年成長11%。因此,由於國內小客車產量的增加,金屬表面處理市場的需求呈現上升趨勢。

- 由於車輛排放法規收緊、車輛安全性提高、車輛駕駛員輔助系統以及零售和電子商務領域物流快速成長,印度對新型和先進輕型商用車 (LCV) 的需求不斷增加。已顯著增加。例如,根據OICA的數據,2022年印度輕型商用車產量達617,398輛,較2021年成長27%,較2020年恢復60%。

- 此外,由於印度汽車工業的投資增加和進步,基底金屬的消費量預計將增加。例如,塔塔汽車在2022年4月宣布,計畫未來5年向小客車業務投資30.8億美元。因此,汽車產量和汽車行業投資的增加預計將增加國內汽車和交通行業對金屬表面處理市場的需求。

- 銅、錫、鎳和鋁是電子工業中常用的金屬。亞洲地區是全球最大的電氣和電子設備生產國,主要由中國、日本、韓國、新加坡和馬來西亞等國家主導。

- 根據 JEITA(日本電子資訊科技協會)的數據,2022 年 12 月日本國內消費性電器產品出貨收益達到 1,252 億日圓(9.6,404 億美元)。同時,3月份是2022年消費性電器產品出貨收益最強勁的月份,金額約為1,255億日圓(9.6635億美元),而5月份則是最弱的月份,金額為864億日圓( 6.6528億美元)。因此,由於該國家電出出貨的增加,金屬表面處理市場的需求預計將增加。因此,憑藉該地區如此有利的趨勢和投資,亞太地區有望主導全球市場。

金屬表面處理產業概述

金屬表面處理市場高度分散。市場的主要企業(排名不分先後)包括OC Oerlikon Management AG、MKS Atotech、Linde plc、C. Uyemura、Honeywell International Inc.等。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 調查先決條件

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 促進因素

- 非洲汽車產量增加

- 對耐用、耐磨和持久的金屬產品的需求不斷增加

- 其他司機

- 抑制因素

- 某些化學品的環境法規

- 增加金屬對塑膠的替代

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代產品和服務的威脅

- 競爭程度

第5章市場區隔

- 類型

- 無機金屬飾面

- 覆層

- 事前處理/表面處理

- 消耗品和備件

- 電鍍

- 鍍鋅

- 無電電鍍

- 化成膜

- 熱噴塗粉末塗料

- 陽極處理

- 電解拋光

- 有機金屬飾面

- 混合金屬飾面

- 無機金屬飾面

- 目的

- 車

- 家用電器

- 硬體

- 航太

- 重型設備

- 電子產品

- 建造

- 其他用途

- 地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲

- 亞太地區

第6章 競爭形勢

- 併購、合資、合作與協議

- 市場佔有率(%)**/排名分析

- 主要企業採取的策略

- 公司簡介

- AE Aubin Company

- ALMCOGROUP

- Auromex Co., Ltd.

- C. Uyemura Co., Ltd.

- DuPont

- Grind Master

- Guyson Corporation

- Honeywell International Inc.

- Linde plc

- MKS|Atotech

- OC Oerlikon Management AG

- OTEC Precision Finish, Inc.

- Plating Equipment Ltd

- POSCO

- Quaker Chemical Corporation

- sequa gGmbH

- TIB Chemicals AG

第7章市場機會與未來趨勢

- 從傳統溶劑型技術轉向新技術的轉變

- 其他機會

The Metal Finishing Market size is estimated at USD 100.69 billion in 2024, and is expected to reach USD 127.17 billion by 2029, growing at a CAGR of 4.78% during the forecast period (2024-2029).

.

The COVID-19 pandemic negatively impacted the market. This was because of the shutdown of the manufacturing facilities and plants due to the lockdown and restrictions. Supply chain and transportation disruptions further created hindrances for the market. However, the industry witnessed a recovery in 2021, thus rebounding the demand for the market studied.

Key Highlights

- Over the short term, the increasing demand for durable, wear-resistant, and long-lasting metal products are some of the factors driving the market's growth.

- On the other hand, the environmental restrictions on some metal finishing chemicals and increasing metal replacement with plastics are expected to hinder the market's growth.

- However, the shift from traditional solvent-borne technologies to newer technologies will likely provide market opportunities during the forecast period.

- Asia-Pacific dominated the global market, with robust demand from end-user industries such as automotive, construction, electronics, and hardware.

Metal Finishing Market Trends

Automotive Segment to Dominate the Market

- The automotive industry dominated the demand for the metal finishing market. Metal finishing is one of the most common methods used to provide a protective layer on the metal components of vehicles.

- Metal finishing is used in vehicle parts such as engines, other under-the-hood components, power steering systems, brake parts and systems, air conditioning components and systems, chassis hardware, climate control components, and fuel systems.

- Metal finishing also includes the application of paints or ceramics. Many small and large automobile parts require their contact surfaces to be smooth, stress-relieved, and without burrs or defects. This enables the automotive engines to achieve a surface with less friction and heat, generating more horsepower and overall better performance.

- The United States is one of the major automotive industries in the world, contributing at least 3% to the country's overall gross domestic product (GDP). The country produced close to 10.06 million units of automobiles, including passenger and commercial vehicles, in 2022, which showed an increase of 10% compared to 2021. Therefore, increasing the production of automobiles in the country is expected to create an upside demand for the metal finishing market.

- In Indonesia, the increasing regulations on vehicle emissions, vehicle safety advancement, driver-assist systems in vehicles, and rapidly growing logistics in the retail and e-commerce sectors have significantly driven the demand for light commercial vehicles. For instance, according to OICA, in 2022, around 1,60,171 units of light commercial vehicles were produced in the country, which showed an increase of 1% compared to 2021. This is expected to create an upside demand for the metal finishing market from the country's light commercial vehicle market.

- Moreover, in the Philippines, the increased demand for goods through e-commerce is pushing the use of light commercial vehicles in logistics, paving the way for light commercial vehicle market growth in the country. Many e-commerce and logistics companies are growing in the country, further boosting the light commercial vehicle market's growth. For instance, in 2022, light commercial vehicle production in the country amounted to 50,560 units, which shows an increase of 68% compared to 2021.

- Furthermore, due to the relaxation of movement control orders in Malaysia, many economic sectors were allowed to re-open businesses in the country, which helped to improve business confidence and contributed to the production of new vehicles, including commercial vehicles, which are much-needed for running businesses. For instance, in 2022, light commercial vehicle production in Malaysia amounted to 52,085 units, which shows an increase an 48% compared to 2021. Therefore, this is expected to support the demand for metal finishing from the country's light commercial vehicles.

- The metal finishing market has the potential for growth in the long term with the emergence of more technologically developed cars.

Asia-Pacific Region to Dominate the Market

- In the Asia-Pacific region, the increasing investments and production in the automotive industry, rising production of electricals and electronics, and surging demand for heavy equipment are some of the major factors driving the market for metal finishing. Multinational companies drive the industrial sector in this region.

- China holds the largest Asia-Pacific market share for the metal finishing market. The demand for the metal finishing market is expected to rise throughout the forecast period due to rising investments and construction activity in the country. China is a huge contributor, as it has been one of the leading investors in infrastructure worldwide over the past few years. For instance, according to the National Bureau of Statistics (NBS) of China, in 2022, the output value of construction works in China amounted to 27.63 trillion yuan (USD 4108.581 billion), an increase of 6.6% compared with 2021.

- Moreover, China is also one of the largest producers of passenger cars due to the improving logistics and supply chains, increased business activity, and the country's raft of pro-consumption measures, among other factors contributing to the passenger car production in the country. For instance, according to OICA, in 2022, passenger car production in China amounted to 2,38,36,083 units, which showed an increase of 11% compared to 2021. Therefore, increasing the production of passenger cars in the country is expected to create an upside demand for the metal finishing market.

- In India, increasing regulations on vehicle emissions, vehicle safety advancement, driver-assist systems in vehicles, and rapidly growing logistics in the retail and e-commerce sectors have been significantly driving the demand for new and advanced Light commercial vehicles (LCVs). For instance, according to OICA, in 2022, light commercial vehicle production in India amounted to 6,17,398 units, showing an increase of 27% compared to 2021 and a recovery of 60% compared to 2020.

- Furthermore, increased investments and advancements in the automobile industry in India are expected to increase the consumption of base metals. For instance, in April 2022, Tata Motors announced plans to invest USD 3.08 billion in its passenger vehicle business over the next five years. Therefore, increasing automobile production and investment in the automobile industry is expected to have an upside demand for the metal finishing market from the country's automotive and transportation industry.

- Copper, tin, nickel, and aluminum are common metals the electronics industry uses. The Asian region is the largest producer of electrical and electronics globally, with countries such as China, Japan, South Korea, Singapore, and Malaysia dominating globally.

- In Japan, according to JEITA (Japan Electronics and Information Technology Association), domestic shipments of consumer electronics in Japan reached a value of JPY 125.2 billion (USD 964.04 million) in December 2022. While March was the strongest month for consumer electronics shipments during 2022, with around JPY 125.5 billion (USD 966.35 million), May was the weakest, with the value falling to JPY 86.4 billion (USD 665.28 million). Therefore, increasing consumer electronics shipments from the country is expected to increase demand for the metal finishing market.

- Hence, with such favorable trends and investments in the region, Asia-Pacific is expected to dominate the global market.

Metal Finishing Industry Overview

The Metal Finishing market is highly fragmented. The major players in this market (not in a particular order) include OC Oerlikon Management AG, MKS Atotech, Linde plc, C. Uyemura Co., Ltd, and Honeywell International Inc., among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Automotive Production in Africa

- 4.1.2 Increasing Requirement for Durable, Wear-resistant, and Long-lasting Metal Products

- 4.1.3 Other Drivers

- 4.2 Restraints

- 4.2.1 Environmental Restrictions on Some Chemicals

- 4.2.2 Increasing Replacement of Metal with Plastics

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size by Value)

- 5.1 Type

- 5.1.1 Inorganic Metal Finishing

- 5.1.1.1 Cladding

- 5.1.1.2 Pretreatment/Surface Preparation

- 5.1.1.3 Consumables and Spares

- 5.1.1.4 Electroplating

- 5.1.1.5 Galvanization

- 5.1.1.6 Electro-less Plating

- 5.1.1.7 Conversion Coatings

- 5.1.1.8 Thermal Spray Powder Coating

- 5.1.1.9 Anodizing

- 5.1.1.10 Electro-polishing

- 5.1.2 Organic Metal Finishing

- 5.1.3 Hybrid Metal Finishing

- 5.1.1 Inorganic Metal Finishing

- 5.2 Application

- 5.2.1 Automotive

- 5.2.2 Appliances

- 5.2.3 Hardware

- 5.2.4 Aerospace

- 5.2.5 Heavy Equipment

- 5.2.6 Electronics

- 5.2.7 Construction

- 5.2.8 Other Applications

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 A.E. Aubin Company

- 6.4.2 ALMCOGROUP

- 6.4.3 Auromex Co., Ltd.

- 6.4.4 C. Uyemura Co., Ltd.

- 6.4.5 DuPont

- 6.4.6 Grind Master

- 6.4.7 Guyson Corporation

- 6.4.8 Honeywell International Inc.

- 6.4.9 Linde plc

- 6.4.10 MKS | Atotech

- 6.4.11 OC Oerlikon Management AG

- 6.4.12 OTEC Precision Finish, Inc.

- 6.4.13 Plating Equipment Ltd

- 6.4.14 POSCO

- 6.4.15 Quaker Chemical Corporation

- 6.4.16 sequa gGmbH

- 6.4.17 TIB Chemicals AG

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Shift from Traditional Solvent-borne Technologies to Newer Technologies

- 7.2 Other Opportunities