|

市場調查報告書

商品編碼

1273521

水刀切割機市場——增長、趨勢、COVID-19 的影響和預測 (2023-2028)Waterjet Cutting Machine Market - Growth, Trends, and Forecasts (2023 - 2028) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

在預測期內,水刀切割機市場的複合年增長率預計為 5.5%。

主要亮點

- 快速工業化導致汽車、製造業等最終用途行業的增長是水刀切割機市場的主要驅動因素。 在製造業中引入機器人水刀切割機和自動化對市場增長產生了重大影響。 亞太地區的水刀切割機市場正在增長。

- 水刀切割機設置時間短,可以切割多種材料。 水刀切割機無需花費時間即可進行設置,可以切割多種材料,通過設置同時工作的多個切割頭最大限度地提高生產率,並且對於包括原型在內的各種尺寸的產品都非常高效。可以做出適當的反應。 通過引入 3D 切割和多軸水刀切割等先進技術,水刀切割有可能更容易和更廣泛地使用。

- 由於 COVID-19 疫情導致封鎖,部分與水刀切割機市場相關的產品停產。 結果,製造水刀切割機的企業被迫停產,阻礙了市場增長。 然而,最近許多運營商已經重新開業並滿負荷運營。 預計市場將在 2023 年初復甦。 現在 COVID-19 已經結束,設備製造商必須專注於保護人員、供應鍊和運營,解決緊迫問題並實施新的工作程序。

水刀切割機市場趨勢

磨料水刀切割機的成長

一種稱為水射流磨料加工的創新非傳統磨料切割技術涉及熔化氧化材料,並對鑄鐵、鋁、鋼和花崗巖等金屬進行拋光和成型。將水噴到工件上。 將水射流加工與 CNC 加工機相結合,可提高加工能力,實現零件的無故障生產,並減少工作時間和成本。

- 在這個過程中,通常有兩種方法,懸浮噴射法和噴射噴射法,將磨料送入切割設備。 但切割材料的實際工作是由磨粒完成的。 水的唯一作用是引導磨料到正確的切削點,並加速到適合切削的速度。 與常規鑽孔和機械鑽孔相比,磨料水刀切割具有無熱效應、加工範圍廣、靈活性高、生產率高和切削力小等優點。

- 工業 4.0 正在推動磨料水刀切割機市場穩步增長。 此外,全球擴張的重工業和工具製造業正在推動市場。 隨著採用創新水刀技術的磨料切割的使用範圍擴大,預計該市場將會增長。 金屬製造行業越來越多地使用磨料水射流切割機進行磨削操作,從而推動了市場需求。 任何涉及石材切割、加工、木工或切割硬質橡膠的工作都需要加砂水刀切割。

- 水刀技術近年來取得了長足的進步,消除了 3D 切割中的流滯和錐度等問題。 加砂水刀機為實現高精度加工提供了巨大的優勢。 它可以在不使用冷卻劑的情況下進行加工,並且可以非常平滑地完成複雜的形狀和切割表面,這是兩大優勢。 磨料水刀切割機還具有生產低成本、環保無毒產品的優勢。

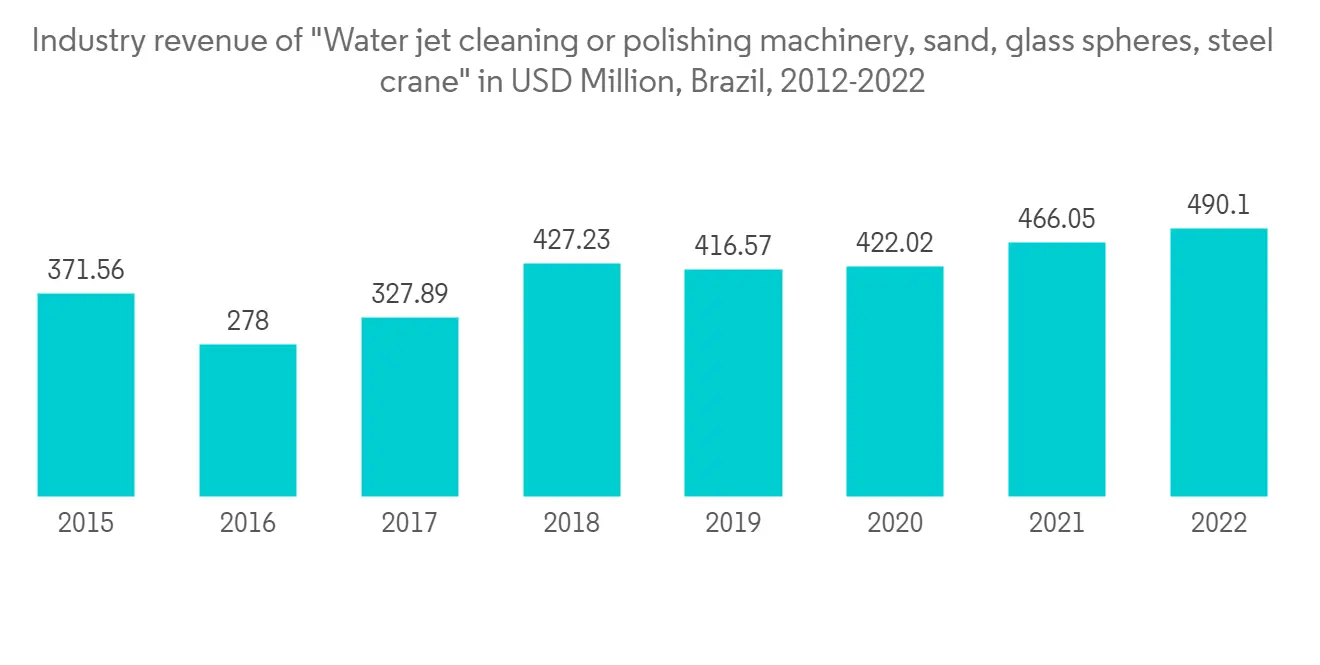

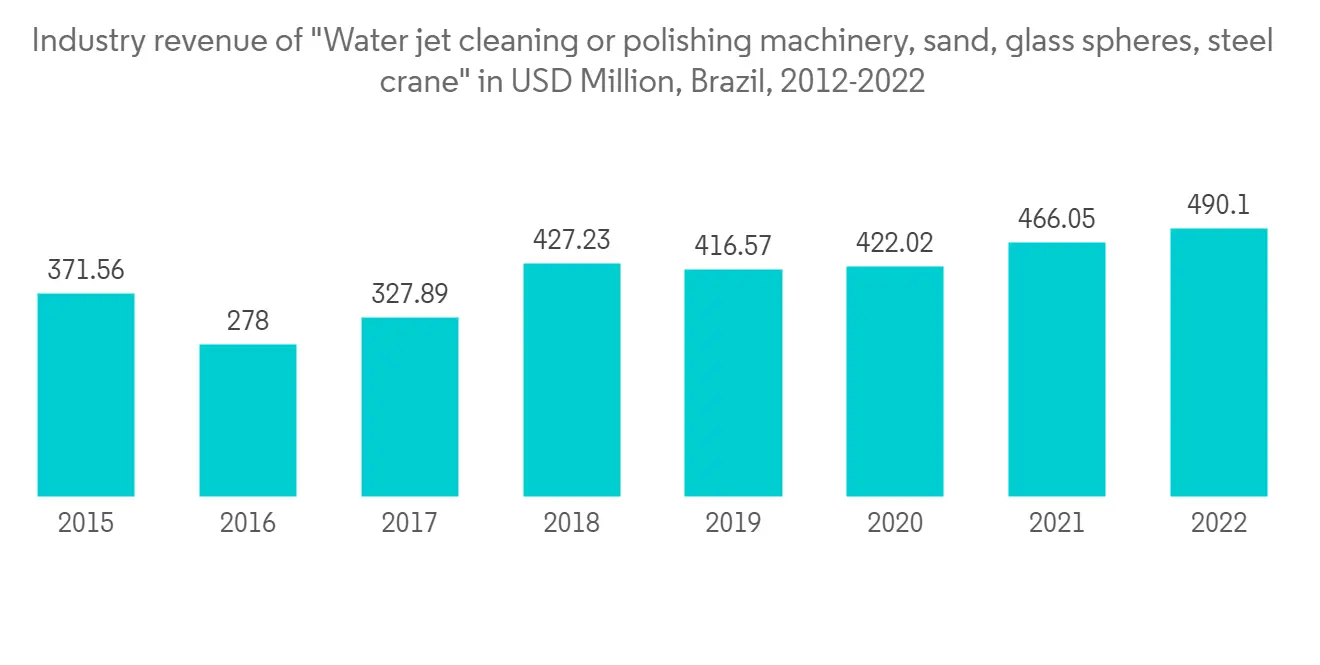

巴西各種規模的製造商,從單人車間到大型原始設備製造商,都在尋找適合添加到其他製造工藝中的磨料水刀切割技術。 在許多情況下,這台機器可以快速生產出可用的成品零件。 然而,也可以提供具有適合於通過常規方法加工的接近成品的形狀的空白區域。 不影響材料質量,不降低常規工作效率。 該設備的緊密嵌套還最大限度地提高了流程中的材料利用率。

主要行業水刀切割自動化流程介紹

- 自動化技術的採用在很大程度上受到整個製造業的技術發展和創新的影響。 通過使用機器人和控制系統等工具來改進製造程序,自動化在各個行業都有所增加。 自動化通過降低生產成本和時間改變了工業水刀切割機領域的製造過程。

- 水刀切割系統的自動化提高了效率,並使在阻塞點的工作更加安全。 在醫療器械領域,也將有利於促進產品開發和新技術的獲取。 航空航天業正在為新的生產技術和自主飛機時代鋪平道路。 在過去幾年中,水刀自動化市場經歷了巨大的增長。

- 由於水刀切割技術能夠切割多種材料,包括複合材料、可燃材料、金屬和玻璃,因此在各個行業中廣受歡迎。 該設備可以使用純水或水和磨料的溶液切割厚度達 10 英寸的鋼板。 例如,Flow International 的 Mach 系列水刀切割機可以切割厚度達 24 英寸的材料。 該技術還允許在石材、玻璃和金屬中快速鑽孔和切割精細細節和精密設計。

- 影響水刀切割機使用的另一個因素是技術創新和進步。 有助於提高最終用戶生產力和精密切割操作的主要發展包括微型、3D 和機器人水刀切割機 (WCM)。 例如,總部位於俄亥俄州的 WARDJet 是一家水刀切割設備製造商,它使用水刀切割機器人自動化技術為航空航天、汽車、電子和紡織行業製作焊接測試樣品。

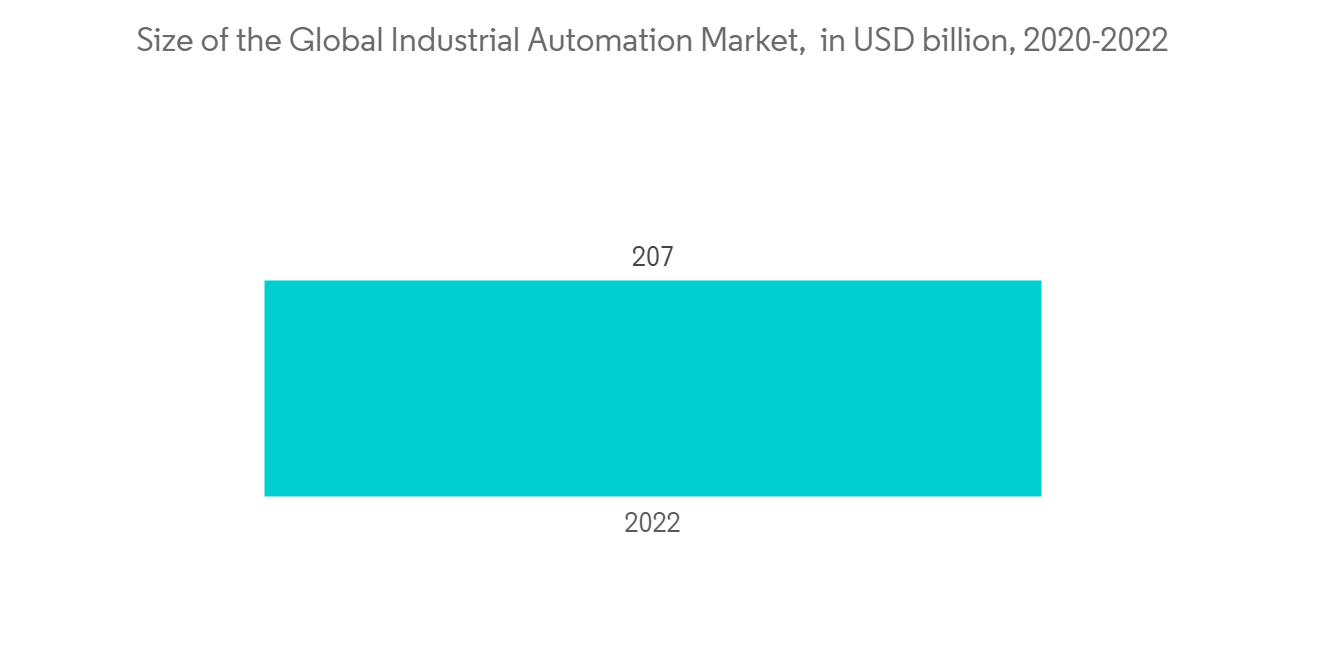

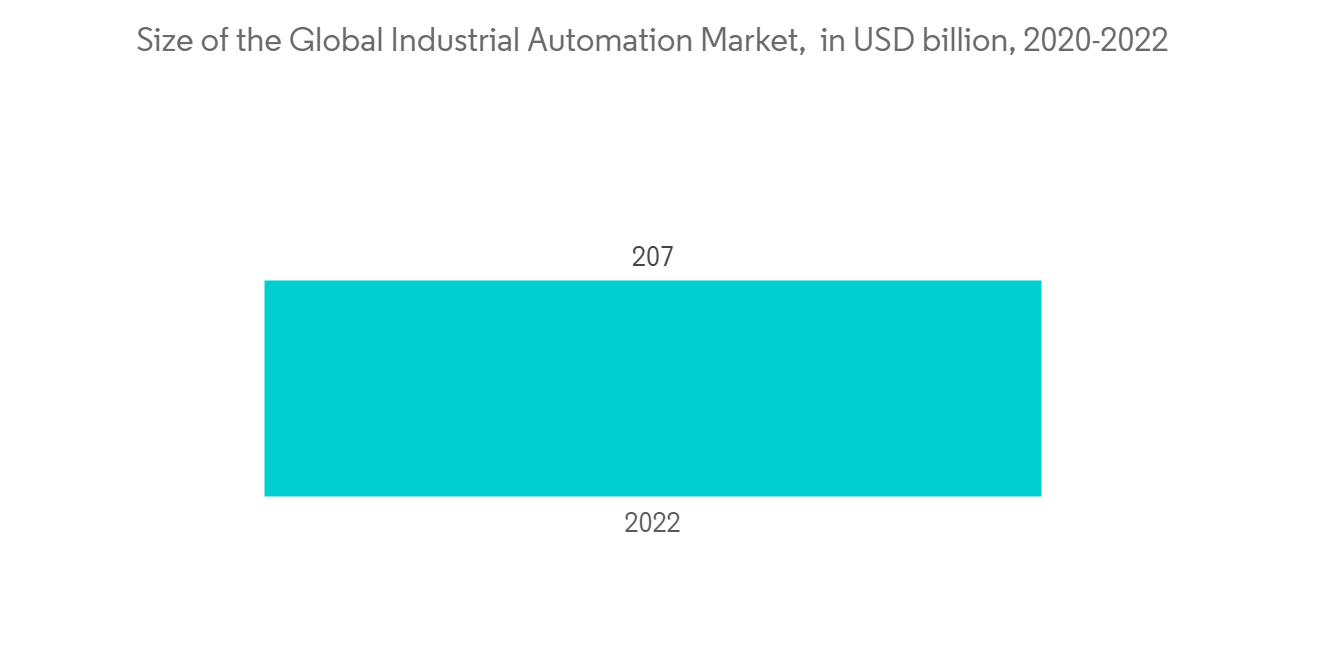

- 隨著對更現代設備的需求激增,預計對水刀切割機的需求將逐年顯著增長。 終端用戶行業越來越關注開發 50,000psi 以上的水刀壓力水平,這是一種常見的超高壓水平。 與其他激光、氧燃料和等離子切割機相比,水刀切割機使用高壓射流和冷切技術來提供乾淨的邊緣並消除翹曲和變形。 隨著包括許多尖端技術和工藝在內的全球自動化市場的擴大,預計該市場將進一步擴大。

水刀切割機行業概況

水刀切割機市場的競爭格局是分散的,據觀察,許多本土企業正在進入該市場。 為了在國際市場上站穩腳跟,領先的水刀切割機供應商致力於開發具有尖端技術的流線型產品。 政府對使用純水刀技術的支持不斷增加,也支持著這一市場的擴大。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

內容

第一章介紹

- 調查結果

- 本次調查的假設

- 本次調查的範圍

第二章研究方法論

第 3 章執行摘要

第 4 章市場洞察和動態

- 當前市場概況

- 市場驅動因素

- 市場製約因素

- 市場機會

- 技術進步

- 產業吸引力 - 波特五力分析

- 新進入者的威脅

- 買方/消費者議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭強度

- COVID-19 對市場的影響

第 5 章市場細分

- 產品類型

- 機器人水刀切割

- 3D 水射流切割

- 微水射流切割

- 最終用戶

- 汽車

- 電子產品

- 航空航天

- 建築學

- 礦業

- 其他行業

- 地區

- 北美

- 美國

- 加拿大

- 墨西哥

- 其他北美地區

- 南美洲

- 巴西

- 阿根廷

- 歐洲

- 德國

- 英國

- 法國

- 俄羅斯

- 西班牙

- 其他歐洲

- 亞太地區

- 印度

- 中國

- 日本

- 其他亞太地區

- 中東

- 阿拉伯聯合酋長國

- 沙特阿拉伯

- 其他中東地區

- 北美

第六章競爭格局

- 市場集中度概述

- 公司簡介

- OMAX Corporation

- Enovis(Colfax Corporation)

- Hypertherm Inc.

- Flow International Corporation

- Wardjet, Belotti SPA

- KMT Waterjet

- Resato International B.V.

- Jet Edge Inc.

- Dardi International Corporation

- Jekran Ltd

- International Waterjet Machines

- Kennametal Inc.

- CERATIZIT S.A.

- GMA Garnet Pty. Ltd.

- Hornet Cutting Systems*

第七章市場前景

第8章附錄

The waterjet cutting machine market is estimated to register a CAGR of 5.5% during the forecast period.

Key Highlights

- The fast industrialization that has led to the growth of end-use industries like automotive, manufacturing, and others is the main driver of the waterjet cutting machine market. Robotic waterjet cutting machines and the introduction of automation in the manufacturing sector have substantially impacted market growth. In the APAC region, there is a sizable market for waterjet cutting devices.

- Waterjet cutters require less setup time and can cut a wide variety of materials. They can be set up with many heads that operate simultaneously to maximize productivity, and they can accommodate all sizes of product runs, including prototype runs, with efficiency. Advanced technologies like 3D cutting and multi-axis waterjet cutting could be introduced to make waterjet cutting easier and more widely used.

- Due to lockdowns caused by the COVID-19 epidemic, several products related to the waterjet cutting machine market were no longer produced. As a result, businesses that make waterjet cutting machines had to stop production, which hampered their market growth. However, in recent times, many operators have reopened and are operating at full capacity. By the beginning of 2023, this is anticipated to aid in the market's recovery. Equipment and machinery manufacturers must concentrate on safeguarding their personnel, supply networks, and operations to deal with urgent problems and implement new working procedures now that COVID-19 is finally over.

Waterjet Cutting Machine Market Trends

Growth Potential of Abrasive Waterjet Cutting Machines

Water is sprayed at the workpiece during the innovative, non-traditional abrasive cutting technique known as waterjet abrasive machining to dissolve oxidized materials and polish and shape metals like cast iron, aluminum, steel, and granite. The abrasive waterjet systems' machining capacity is increased when an abrasive jet machining method is combined with a CNC machine, enabling hassle-free component production and decreasing operational time and costs.

- During this process, the abrasive material is typically pumped into the cutting apparatus using two different systems: suspension jet systems and injection jet systems. However, the actual task of cutting the material is done by the abrasive particle. Water's only function is to guide abrasive particles to the correct cutting point and accelerate them to a speed appropriate for cutting. In conventional or mechanical drilling processes, abrasive waterjet cutting offers some advantages like no thermal effect, high machining variety, high flexibility, high productivity, and minimal cutting force.

- Industry 4.0 is driving steady growth in the market for abrasive waterjet cutting machines. Additionally, the market is driven by the globally expanding heavy industry and tool manufacturing sectors. The market would expand because of increasing abrasive cutting applications for innovative waterjet technology. The market demand is driven by the expanding use of polishing tasks on abrasive waterjet cutting machines in the metal production sectors. Abrasive waterjet cutting is required for every job involving stone cutting, fabrication, woodworking, or even the cutting of hard rubber.

- Waterjet technology has advanced significantly in recent years, eliminating the problems of stream lag and tapering in 3D cutting. Abrasive waterjet machines offer significant benefits for achieving high-precision machining. The ability to machine without a refrigerant and produce intricate forms and cuts with great surface smoothness are two major advantages. Abrasive waterjet cutting machines also have the advantages of being less expensive, environmentally friendly, and producing non toxic byproducts.

Brazilian manufacturers of all sizes, from one-man shops to major OEMs, are discovering that the abrasive waterjet cutting technique is the perfect addition to their other manufacturing procedures. In many instances, this machinery can swiftly produce a finished, usable part. However, it can also provide a nearly finished or shaped blank area that is appropriate for subsequent processing using traditional methods. The efficiency of traditional operations is not diminished by the abrasive waterjet process because it does not affect the material qualities. This equipment's ability to nest closely maximizes material usage in the process as well.

Implementation of Waterjet Cutting Automation Process Across Major Industries

- The adoption of automation technologies has been greatly influenced by the evolution of technological advancements and innovation throughout manufacturing units. By utilizing tools like robotics and control systems to improve manufacturing procedures, automation has increased throughout industries. Automation has changed the manufacturing process in the industrial waterjet-cutting machine sector by reducing production costs and time.

- Automation in waterjet cutting systems is improving efficiency and making workplaces safer at transportation hubs. It is promoting product development and enabling staff to master new technologies in the medical device sector. Additionally, it is paving the way for new production techniques and an era of autonomous aircraft in the aerospace industry. Over the past few years, the waterjet automation market has experienced tremendous growth.

- Because of its adaptability in cutting several materials, including composites, combustible materials, metals, and glass, waterjet cutting technology is becoming more popular among various industries. The equipment can cut steel plates that are up to 10 inches thick using either pure water or a solution of water and abrasive material. For instance, the Mach line of waterjet cutting machines from Flow International Corporation can cut materials up to 24 inches thick. The technology also makes it possible to quickly drill or cut small details or precise designs in stones, glass, and metals, among other tasks.

- Another element that has affected the use of waterjet cutting machines among industries is technological innovation and advancement. Some of the key developments that assist end users in increasing their productivity and producing precise cutting operations include micro, 3D, and robotic waterjet cutting machines (WCMs). For example, WARDJet, which is based in Ohio and makes equipment for waterjet cutting, uses robotic automation for waterjet cutting to make weld test samples for the aerospace, automotive, electronic, and textile industries.

- With a surge in demand for more modern equipment, it is projected that the need for waterjet cutting machines will increase significantly every year. The end-user industries are becoming more interested in the development of waterjet pressure levels above the typical ultra-high-pressure levels of 50,000 psi. In contrast to other lasers, oxy-fuel, or plasma-cutting machines, the waterjet cutting machines use a high-pressure level jet and cold-cutting technology to give a clean edge and eliminate warping and distortion. The market is likely to grow even more as the global market for automation, which includes many cutting-edge technologies and processes, grows.

Waterjet Cutting Machine Industry Overview

The waterjet cutting machine market's competitive landscape is observed to be fragmented, with many local players operating in the market. To establish themselves in the international market, major suppliers of waterjet cutting machines are putting their efforts into developing items that are streamlined with cutting-edge technologies. The growing governmental support for using pure waterjet technology is another reason supporting this market's expansion.

OMAX Corporation, Enovis (Colfax Corporation), Flow International Corporation, Resato International B.V., and Belotti SPA are some of the leading players operating in the waterjet cutting machine market.

Some other major players in the market are KMT Waterjet, Hypertherm Inc., Jet Edge Inc., Dardi International Corporation, Jekran Ltd., International Waterjet Machines, Kennametal Inc., CERATIZIT S.A., GMA Garnet Pty. Ltd., Hornet Cutting Systems, etc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS & DYNAMICS

- 4.1 Current Market Overview

- 4.2 Market Drivers

- 4.3 Market Restraints

- 4.4 Market Opportunities

- 4.5 Technological Advancements

- 4.6 Industry Attractiveness - Porter's Five Forces Analysis

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Buyers/Consumers

- 4.6.3 Bargaining Power of Suppliers

- 4.6.4 Threat of Substitute Products

- 4.6.5 Intensity of Competitive Rivalry

- 4.7 Impact of COVID-19 on the Market

5 MARKET SEGMENTATION

- 5.1 Product Type

- 5.1.1 Robotic Waterjet Cutting

- 5.1.2 3D Waterjet Cutting

- 5.1.3 Micro Waterjet Cutting

- 5.2 End-User

- 5.2.1 Automative

- 5.2.2 Electronics

- 5.2.3 Aerospace

- 5.2.4 Construction

- 5.2.5 Mining Industry

- 5.2.6 Other Industries

- 5.3 Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Mexico

- 5.3.1.4 Rest of North America

- 5.3.2 South America

- 5.3.2.1 Brazil

- 5.3.2.2 Argentina

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Russia

- 5.3.3.5 Spain

- 5.3.3.6 Rest of Europe

- 5.3.4 Asia-Pacific

- 5.3.4.1 India

- 5.3.4.2 China

- 5.3.4.3 Japan

- 5.3.4.4 Rest of Asia-Pacific

- 5.3.5 Middle East

- 5.3.5.1 United Arab Emirates

- 5.3.5.2 Saudi Arabia

- 5.3.5.3 Rest of the Middle East

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration Overview

- 6.2 Company Profiles

- 6.2.1 OMAX Corporation

- 6.2.2 Enovis (Colfax Corporation)

- 6.2.3 Hypertherm Inc.

- 6.2.4 Flow International Corporation

- 6.2.5 Wardjet, Belotti SPA

- 6.2.6 KMT Waterjet

- 6.2.7 Resato International B.V.

- 6.2.8 Jet Edge Inc.

- 6.2.9 Dardi International Corporation

- 6.2.10 Jekran Ltd

- 6.2.11 International Waterjet Machines

- 6.2.12 Kennametal Inc.

- 6.2.13 CERATIZIT S.A.

- 6.2.14 GMA Garnet Pty. Ltd.

- 6.2.15 Hornet Cutting Systems*